Tommy Fury wants to prove he’s more than just the boy who fumbled.

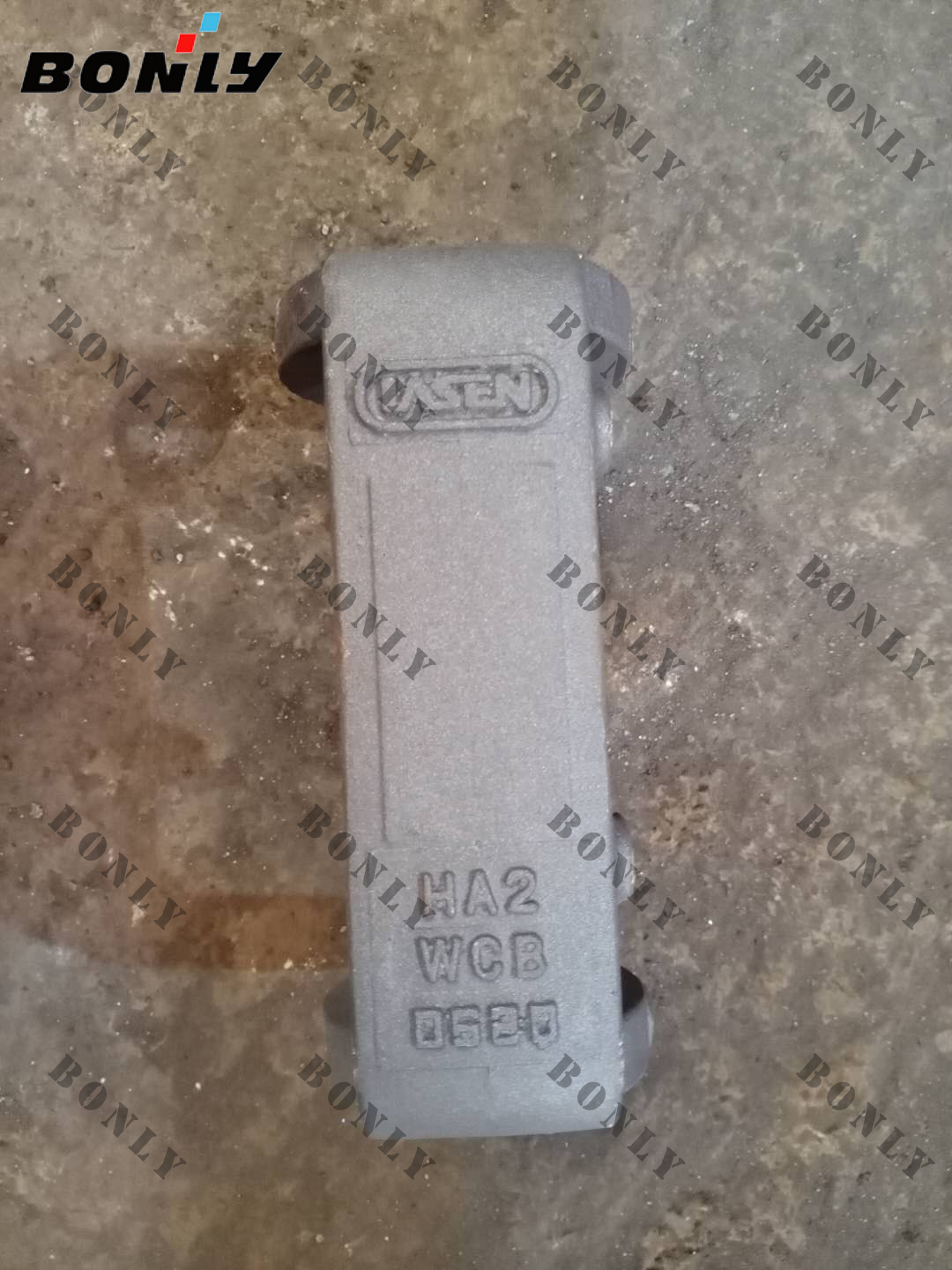

The means to that end is a knockout victory over YouTube sensation Jake Paul when they collide atop the ESPN+ and FITE+ pay-per-view (PPV) boxing event this Sunday afternoon (Feb. 26, 2023) from Diriyah, Saudi Arabia. Hook Type Abrator

THE TRUTH! International superstar and serial risk-taker, Jake “The Problem Child” Paul, will face the biggest challenge of his budding combat sports career when he takes on his first-ever professional boxer, Tommy “TNT” Fury, inside Diriyah Arena in Diriyah, Saudi Arabia, streaming live on ESPN pay-per-view (PPV). “Paul vs. Fury,” which will also feature WBC Cruiserweight kingpin, Ilunga Makabu, battling former WBC and WBA champion, Badou Jack, in the co-main event, special start time is slated for 2 p.m. ET, with a PPV price tag of $49.99.

Don’t miss a single second of face-punching action!

Fury was showing off his punching power during a recent visit to “Shopping for Sneakers” and I found it strange that a sneaker store would have a punch machine. It would be like a glove store having a treadmill but sure, let’s go with it.

Here’s a condensed clip:

Tommy Fury’s jab is DIFFERENT (via @KickGameUK) pic.twitter.com/JU1cYmi7T9

Still no match for skinny, scarf-wearing hippies.

“When I’m done, this guy will never box ever again,” Fury told Sky Sports. “I’ve never been a man to speak about sparring sessions, but I can quietly confirm that sparring has been brutal. I’m dealing with people in the gym on a regular basis that would knock Jake Paul into next week.”

Paul is currently a -180 favorite at DraftKings Sportsbook.

For the rest of the Paul vs. Fury fight card and PPV lineup click here. To order their boxing PPV event on Sunday click here or here.

Check your inbox for a welcome email.

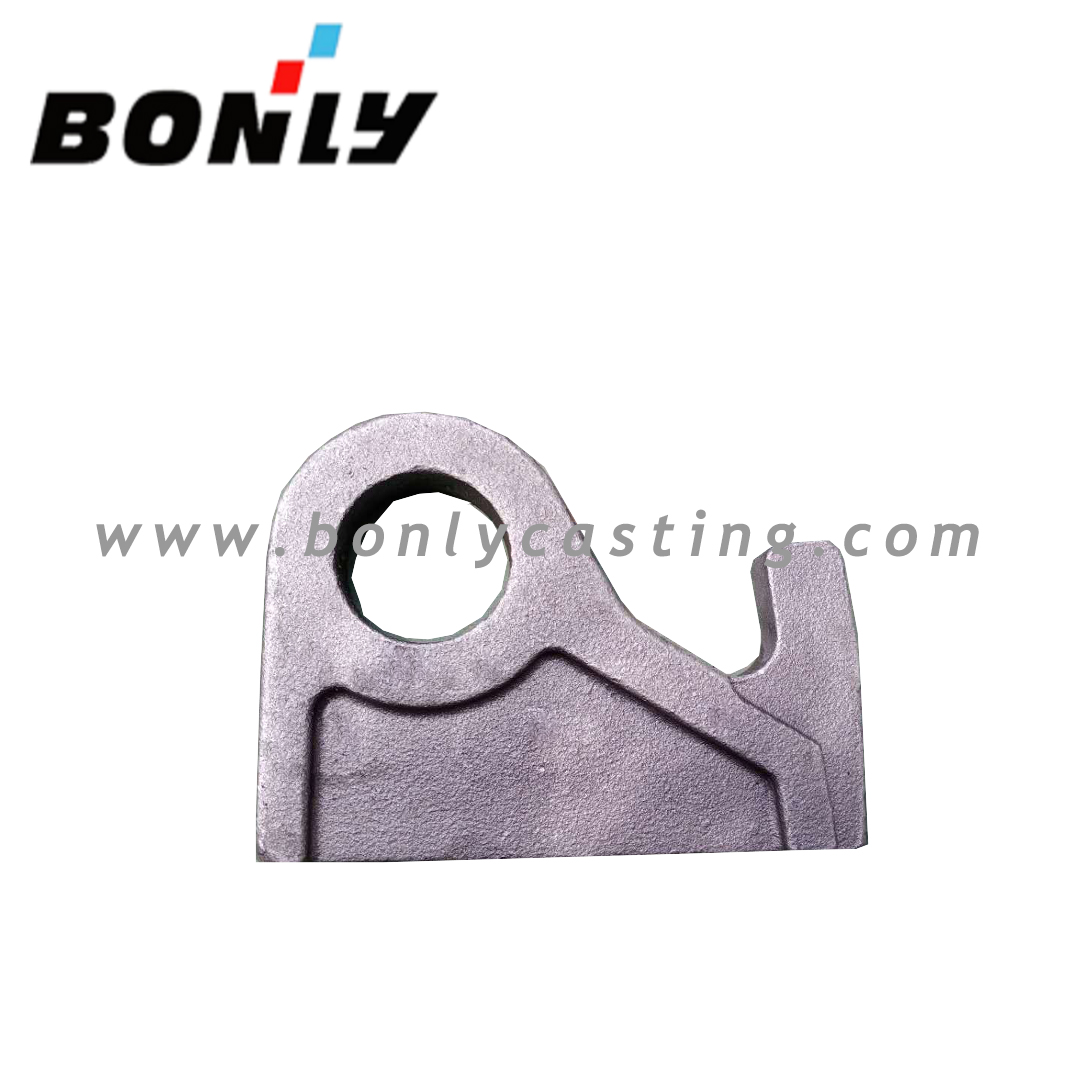

Fired Boiler Parts Oops. Something went wrong. Please enter a valid email and try again.