A single wine bottle holder is a decorative way to show off a prized bottle of wine. Many wine enthusiasts like single wine bottle holders because they provide an attractive conversation piece on the countertop or table while their guests are enjoying wine.

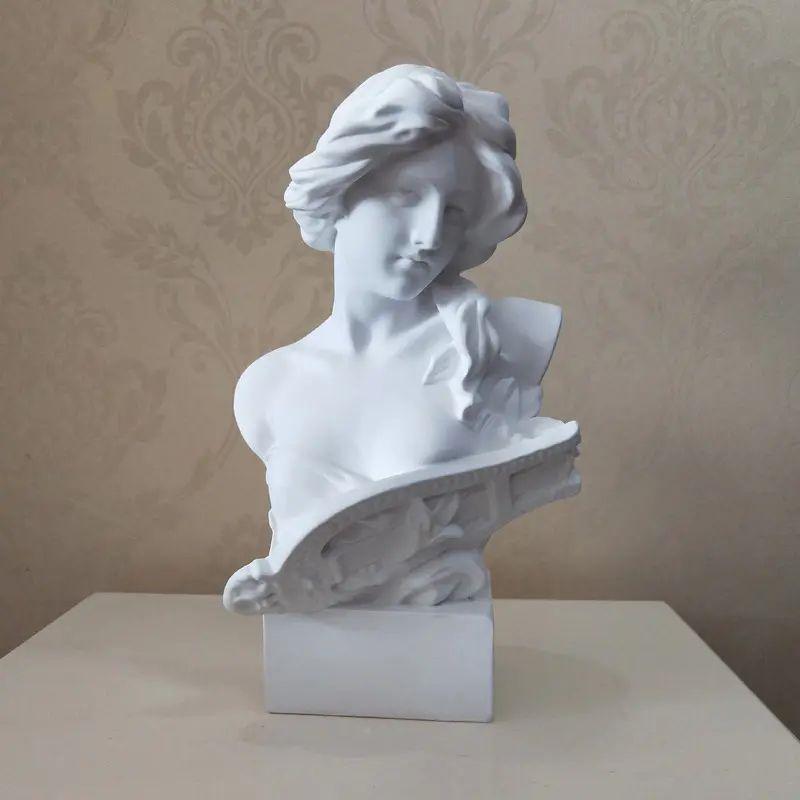

The stylish and charming design of the goddess statue wine holder presented here is a perfect example of decorative wine holder. The shape of this wine rack is an elegant girl statue, beatuiful and attrictive. Although it can hold any types of bottle wine, but its color scheme perfectly matches the red wine. It can be a perfect table decoration even you don’t use it as wine holder. Resin Climbing Man Wall Sculpture

We are a participant in the Amazon Services LLC Associates Program. If you make a purchase, Design Swan may earn an affiliate commission. Please read our disclosure for more info.

High-end color matching, made of cold cast resin, polished by hand.

This wine rack can store red wine, champagne and non-alcoholic bottled beverages.

Whether you need a wine rack or just admire tabletop sculptures, this statue rack is ready to become your favorite wine accessory.

It is suitable for your kitchen, restaurant or bar decoration, and can also be used as an intimate gift for weddings, birthdays or housewarming gifts.

Launched in 2008, DesignSwan is a web blog devoted to uncovering and sharing the latest and greatest design, inspiration, graphics and technology from all over the world.

Cast Resin Sculpture Please noted, this site may contain affiliate links. Please read our disclosure for more info.