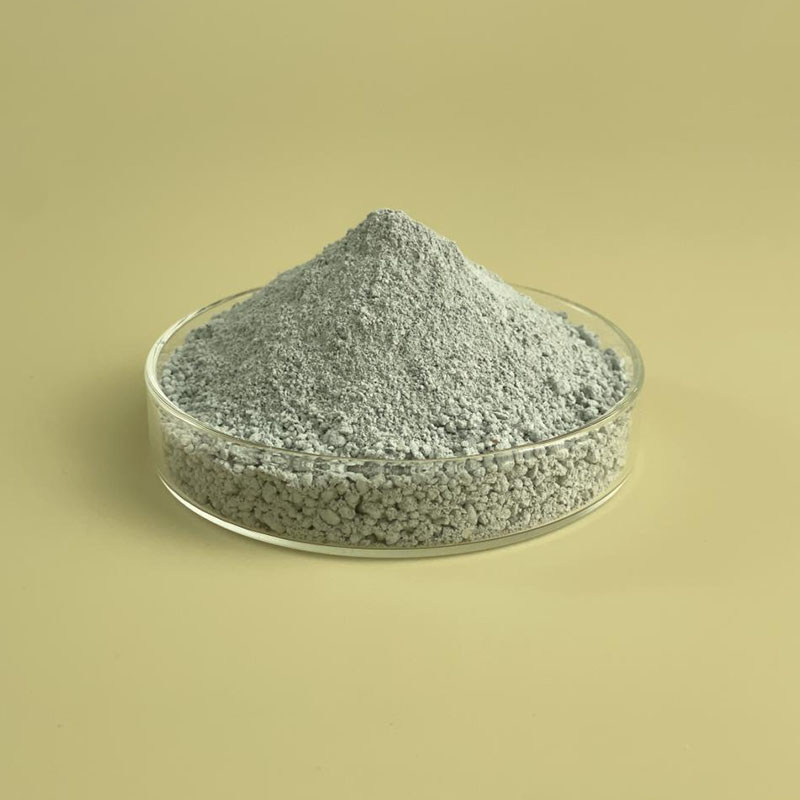

For plastering work, consumers and specifiers have to depend on ordinary cement which is meant for general applications. For plastering, the key requirements are – coverage, crack resistance and finish. Ramco Super Plaster is a non-refractory plaster and brick mortar concentrate which has several advantages like greater workability, lesser rebound loss, higher productivity, higher coverage of 10% and more, superior finish, crack freemasonry, M-Sand compatibility and higher durability.

“Ramco Super Plaster is a value added mortar product, engineered purely for plastering and brickwork. The product provides increased coverage and better crack resistance to the walls. It also gives excellent workability with M-sand” said CEO A V Dharmakrishnan. Refractory Insulation Bricks

With a series of cement and cement-related product launches, RAMCO CEMENTS becomes a complete solutions provider. “Ramco Super Plaster is launched with the objective of segmenting the market and focusing on RIGHT PRODUCT FOR RIGHT APPLICATION” said Balaji K Moorthy, Executive Director (Marketing). As a word of caution he added “Ramco Super Plaster is not to be used for load bearing applications and is to be used for plastering and brickwork only.”

The product has been launched in a convenient 25 kg bag which ensures easy handling and lesser wastage. The Chairman and Managing Director, P R Venketrama Raja, remarked “I would say that the correct solution for plastering and brick mortar today, is this revolutionary product which is very easy to use and comes in a new 25 kg packaging so that this can be applied even for small applications. One can easily transport it and use it for small works too.”

Ramco Cements were the pioneers in introducing the blended Portland Pozzolana Cement with the launch of Ramco Supergrade way back in 1998. Subsequently Ramco Supersteel, a Portland Slag cement was launched in 2000. Then in 2014, the company came up with Ramco Superfast, a customised cement, exclusively for block manufacturing. In 2019, a premium brand of blended cement, Ramco Supercrete was launched for crack-free concreting applications. Apart from the various cements for specific applications, Ramco Cements had also introduced a range of dry mix products like Ramco Tile Fix, Ramco Block Fix, Ramco Superfine Wall Putty, Ramco Self Curing Plaster, Ramco Tile Grout.

Now, with the launch of this new product, Ramco Super Plaster (a non refractory plaster and brick mortar concentrate), Ramco Cements has once again emerged as a solution provider, market leader and innovator in the industry by continuing its commitment of providing Right Products for Right Application.

RAMCO has the most modern RAMCO Research and Development centre in Chennai - an independent state of the art research centre - which not only continuously and independently monitors the quality of cement or concrete produced by its own plants but also carries out tests for customers.The research centre is continuously engaged in research and in development of specialised cements for specific applications for specific market segments. The research centre is also fully equipped to carry out most advanced studies on the durability of concrete and to develop new products to strengthen the brand as the complete cement solution provider.

Ramco Cements Limited, the pioneers in the cement industry, launched Ramco Super Plaster, a revolutionary plastering solution for plastering and brick work. For plastering work, consumers and specifiers have to depend on ordinary cement which is meant for general applications. For plastering, the key requirements are – coverage, crack resistance and finish. Ramco Super Plaster is a non-refractory plaster and brick mortar concentrate which has several advantages like greater workability, lesser rebound loss, higher productivity, higher coverage of 10% and more, superior finish, crack freemasonry, M-Sand compatibility and higher durability. “Ramco Super Plaster is a value added mortar product, engineered purely for plastering and brickwork. The product provides increased coverage and better crack resistance to the walls. It also gives excellent workability with M-sand” said CEO A V Dharmakrishnan. With a series of cement and cement-related product launches, RAMCO CEMENTS becomes a complete solutions provider. “Ramco Super Plaster is launched with the objective of segmenting the market and focusing on RIGHT PRODUCT FOR RIGHT APPLICATION” said Balaji K Moorthy, Executive Director (Marketing). As a word of caution he added “Ramco Super Plaster is not to be used for load bearing applications and is to be used for plastering and brickwork only.” The product has been launched in a convenient 25 kg bag which ensures easy handling and lesser wastage. The Chairman and Managing Director, P R Venketrama Raja, remarked “I would say that the correct solution for plastering and brick mortar today, is this revolutionary product which is very easy to use and comes in a new 25 kg packaging so that this can be applied even for small applications. One can easily transport it and use it for small works too.” Ramco Cements were the pioneers in introducing the blended Portland Pozzolana Cement with the launch of Ramco Supergrade way back in 1998. Subsequently Ramco Supersteel, a Portland Slag cement was launched in 2000. Then in 2014, the company came up with Ramco Superfast, a customised cement, exclusively for block manufacturing. In 2019, a premium brand of blended cement, Ramco Supercrete was launched for crack-free concreting applications. Apart from the various cements for specific applications, Ramco Cements had also introduced a range of dry mix products like Ramco Tile Fix, Ramco Block Fix, Ramco Superfine Wall Putty, Ramco Self Curing Plaster, Ramco Tile Grout. Now, with the launch of this new product, Ramco Super Plaster (a non refractory plaster and brick mortar concentrate), Ramco Cements has once again emerged as a solution provider, market leader and innovator in the industry by continuing its commitment of providing Right Products for Right Application. RAMCO has the most modern RAMCO Research and Development centre in Chennai - an independent state of the art research centre - which not only continuously and independently monitors the quality of cement or concrete produced by its own plants but also carries out tests for customers.The research centre is continuously engaged in research and in development of specialised cements for specific applications for specific market segments. The research centre is also fully equipped to carry out most advanced studies on the durability of concrete and to develop new products to strengthen the brand as the complete cement solution provider.

Tata Power has significantly bolstered India's electric vehicle (EV) infrastructure by deploying over 850 EV charging points and supporting 2300 electric buses across the country. This initiative underscores Tata Power's commitment to promoting sustainable mobility solutions and enhancing EV adoption nationwide. The EV charging points, strategically located in key urban and semi-urban areas, aim to facilitate convenient and widespread access to charging facilities for electric vehicle users. Tata Power's extensive network of charging stations plays a crucial role in addressing range anxiety a..

A luxury mansion in London, once owned by Hui Ka Yan, chairman of beleaguered Chinese property developer China Evergrande Group, has been sold for $57 million. Located in the exclusive Knightsbridge area, the mansion was part of Hui?s extensive property portfolio. The mansion's sale follows a series of high-value asset disposals by Hui, aimed at addressing Evergrande's financial troubles. The property features luxurious amenities, including multiple bedrooms, expansive living spaces, and a swimming pool, epitomizing opulence. China Evergrande, once one of China's largest property developers,..

In a recent inspection, authorities in Noida have found that 131 residential societies lack adequate fire safety equipment, raising significant concerns about residents' safety. The findings were part of a broader fire safety audit conducted across the city to ensure compliance with safety regulations. The audit revealed that these societies either lacked essential fire safety equipment such as fire extinguishers, hydrants, and smoke detectors, or had non-functional systems. Many buildings were also found to have blocked or poorly maintained emergency exits, which could hinder evacuation effo..

Construction World (CW) is India’s premier and largest circulated construction business magazine, covering the gamut from projects, latest construction news in India, construction trends, policies and people to topical concerns, and technology, with reason, intelligence, and objectivity.

A-303, Navbharat Estates, Zakaria Bunder Road, Sewri (West), Mumbai - 400 015, Maharashtra, India

"Now get regular updates from CW Magazine on WhatsApp!

Join the CW WhatsApp channel for the latest news, industry events, expert insights, and project updates from the construction and infrastructure industry.

Click the link below to join"

By creating an account, you agree to our Terms and Conditions and have read and acknowledge the Privacy Policy

RegisterStay Updated on India's Construction Economy

Subscribe to CW's Daily Newsletter With Handpicked and Curated Stories

On the latest construction news through our weekly newsletter

Thank you for subscribe our newsletter

Refractory Mass Don't miss out on valuable insights and opportunities to connect with like minded professionals