The ModuMiniTurn tool system incorporates a specialized coupling mechanism between the modular head and tool shank.

Tungaloy has updated its ModuMiniTurn modular turning-tool system for Swiss machines by adding 30 new, round-shank toolholders that are suitable for machining the back side of the parts in the subspindle. Bicycle tire studs

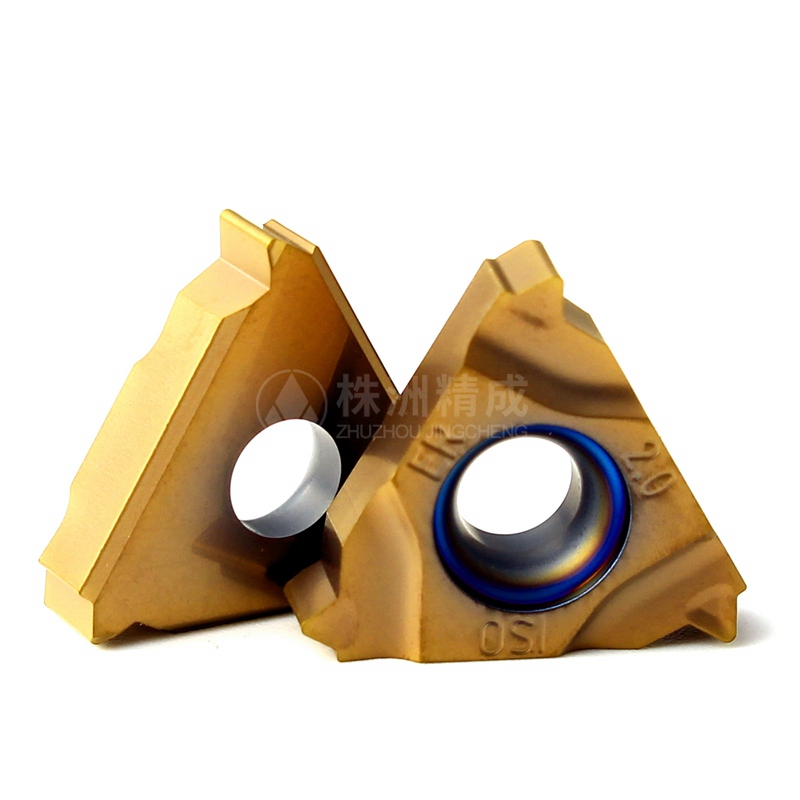

The ModuMiniTurn modular turning tool system incorporates a specialized coupling mechanism between the modular head and tool shank, which reportedly achieves repeatability accuracy within the 5-μm range and minimizes downtime during tooling changeovers. The system offers standard modular heads for a range of applications, including forward turning, back turning, grooving, thread turning, parting and productive Y-axis turning.

The new round shank toolholders are designed to fit the cylindrical-shank toolholders in most Swiss-type lathes. Similar to existing ModuMiniTurn square-shank toolholders, the new round-shank toolholders also feature highly repeatable accuracy, reducing downtime.

The modular heads for the round-shank toolholders have a QR12 coupling connection and are available for forward turning, grooving and thread-turning applications. The forward-turning modular heads come in three standard cutting-angle styles: L for 95 degrees, U for 93 degrees and Q for 107.5 degrees, enabling operators to select optimal cutting angles for operations by swapping the modular cutting heads for the inserts.

The shank diameters are available in 16 mm (0.630″), 19.05 mm (0.75″) and 20 mm (0.787″).

Liquid coolant offers advantages unrelated to temperature. Forced air is the fluid of choice in this shop...but even so, conventional coolant can't be eliminated entirely.

Creating threaded holes in titanium alloys calls for proper techniques based on an understanding of both the properties of these materials and the peculiarities of the tapping process.

Apmt1604 Reducing cutting fluid use offers the chance for considerable cost savings. Tool life may even improve.