Daniels Manufacturing Corporation (DMC ) has announced that its LaceLok Cable Lacing Fasteners is now qualified to MIL-DTL-32554 and MIL-DTL-32555. This fastening technology is a direct replacement for lacing tape/string ties and cable ties for secondary support of wire harnesses.

LaceLok offers a solution for secondary wire-harness support, providing a direct replacement for hand-tied lace and cable ties. The system consists of LaceLok Cable Lacing Fasteners and the LaceLok Installation Tool that, when combined, offer safer and more effective results. Releasable Beaded Cable Ties

Hand-tied lace and plastic cable ties have been the primary options for wire harness secondary support for more than 50 years. Unfortunately, both methods present significant ergonomic, safety, and consistency risks.

Hand-tied lace often causes fatigue and repetitive motion injuries. It’s often applied inconsistently as the applied tension can vary from operator to operator or across the duration of an operator’s shift.

Alternatively, cable ties offer a large profile that can damage adjacent cables and sharp edges after the excess cable tie is cut off.

Typically, plastic cable ties are also less resistant to temperature ranges and several common chemicals. For these and other reasons, the U.S. military has approved LaceLok, but prohibited the use of plastic cable ties on aerospace wire harnesses per the Joint Services Manual NAVAIR 01-1A-505-1.

DMC is a recognized manufacturer of Mil Spec qualified tooling for aerospace and other high-reliability electrical systems.

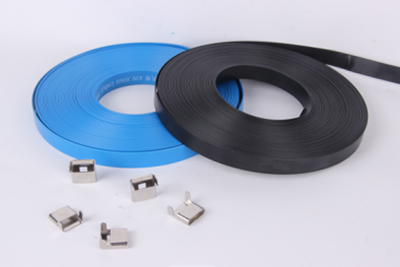

LaceLok combines the ease of cable ties with the abrasion and chemical resistance of lacing tape. The LaceLok system consists of LaceLok and the LaceLok Installation Tool.

LaceLok is constructed with the same Nomex lacing tape used in hand-tied lace. The Nomex lace is attached by aramid fiber thread to an ultra-high temperature thermoplastic fastener head. LaceLok can withstand extreme temperatures from -76° F to 500° F and is resistant to hydraulic fluid, jet fuel, lubricating oil, and isopropyl alcohol. LaceLok is offered in a variety of lengths from 6 to 24 inches long, and can be wrapped once, twice, or three times around wire bundles to provide tensile strengths of 55 to 165 lbs.

Using LaceLok is simple and ergonomic. The user wraps LaceLok around the bundle and squeezes the trigger two to three times to tighten, lock, and terminate the fastener. The resulting loop force is controlled by the fastener, not the user.

Browse the most current issue of Design World and back issues in an easy to use high quality format. Clip, share and download with the leading design engineering magazine today.

Top global problem solving EE forum covering Microcontrollers, DSP, Networking, Analog and Digital Design, RF, Power Electronics, PCB Routing and much more

The Engineering Exchange is a global educational networking community for engineers. Connect, share, and learn today »

Pvc Ties Copyright © 2024 WTWH Media LLC. All Rights Reserved. The material on this site may not be reproduced, distributed, transmitted, cached or otherwise used, except with the prior written permission of WTWH Media Privacy Policy | Advertising | About Us