PINE VALLEY, Calif. (KGTV) - Loved ones are mourning the loss of an East County teen, a week after a one-car crash, after he left work.

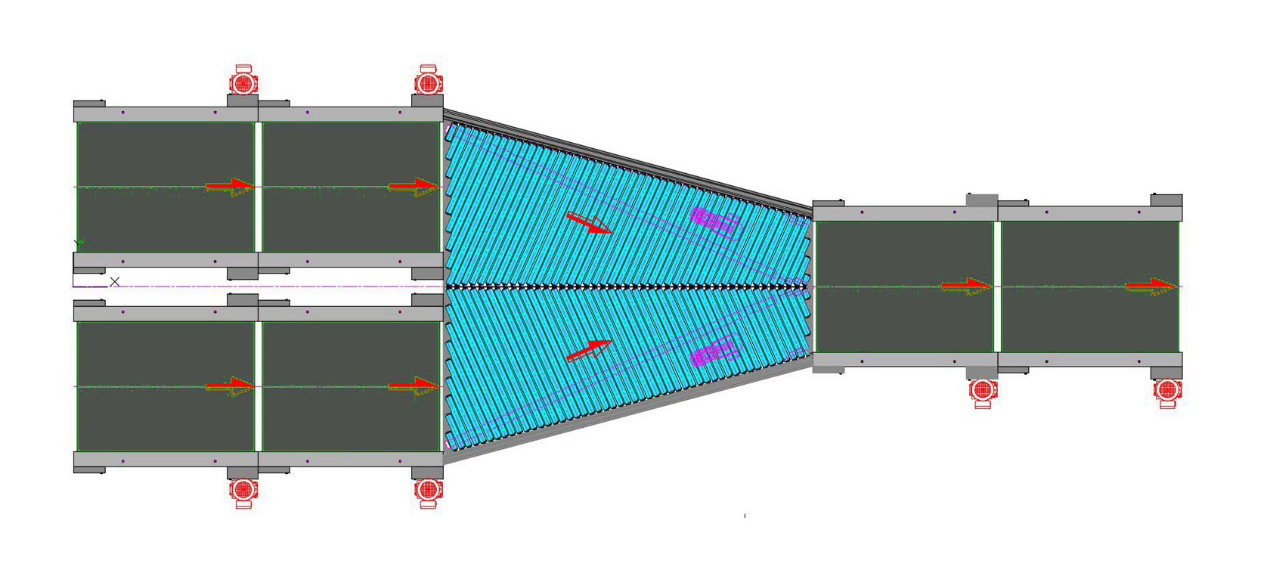

Jason Spirz met our crew along Old Highway 80 in Pine Valley, the second time he's stopped here since the accident. Narrow-Belt Cross Belt Sorter

“It’s going to hurt, every time I go near this place,” said Spirz.

A week ago, around 11 p.m., his 18-year-old son Josh was halfway to his Campo home, after a shift as a cook at Descanso Junction Restaurant, when his Toyota Camry rounded a curve.

According to skid marks, it's believed he lost control around the corner, before spinning out and crashing into a rocky embankment.

The CHP says the car flipped, and Josh, not wearing a seatbelt, was ejected. He would die at the scene.

“The world stopped. I didn't know what to do. I couldn't process it,” said Spirz.

Spirz calls his son, who played football and graduated from Mountain Empire High, kind, adventuresome, and funny.

“We go for a quiet walk, and he’d have some antics to make us all bust up the whole time,” said Spirz.

Spirz says Josh has recently discovered his passion for cooking, after being promoted from dishwasher at Descanso Junction Restaurant.

“He would come home with crazy creations he decided to try out,” said Spirz.

Spirz says as unique and special as his son was, he could also be stubborn.

“He didn’t wear a seatbelt. Everyone who loved him asked him to wear one. Thickheaded. Just lived a little too carefree,” said Spirz.

After the crash, Spirz found his son's belt buckle at the scene.

“This is going nowhere. Will take it out to remember him,” said Spirz.

Spirz hopes by sharing the story of his son’s life and death, lives will be saved.

“If he could be a lesson for everybody, it's safe, buckle your seat belt,” said Spirz.

A Gofundme campaign has been set up to help the family with funeral expenses.

The investigation into the crash is ongoing.

Mail Sorting System Meantime, the CHP spokesperson says while California has a 97% compliance for seat belts, half of all fatal crashes involve people who aren't strapped in, or not properly restrained.