China has been the world’s factory for over four decades – but that could be changing soon, as even Chinese firms are moving supply chains out of the country.

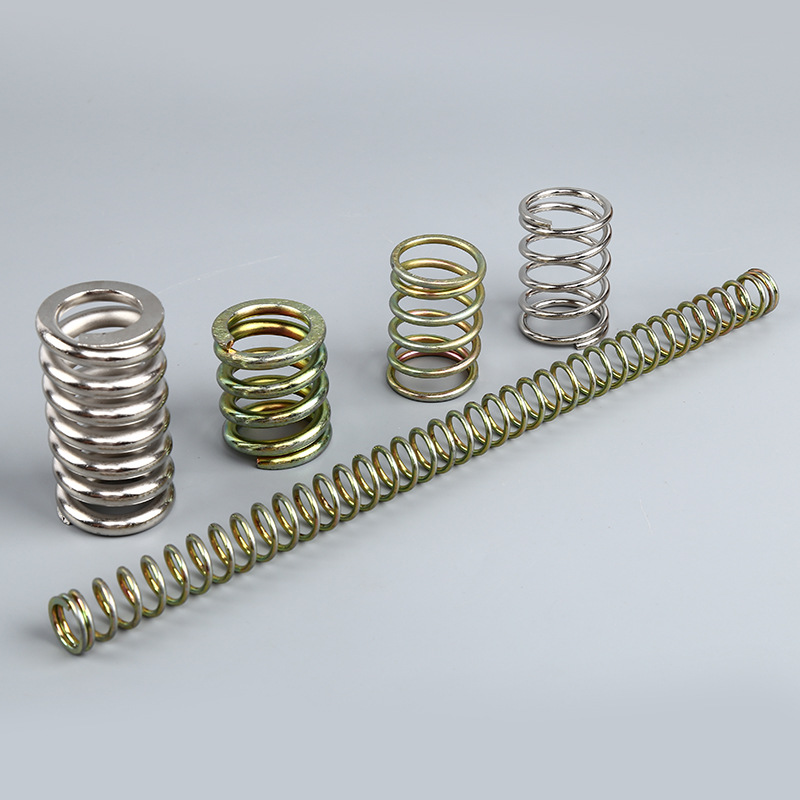

While Western countries have already been doing this since 2018 after then-president Donald Trump launched a trade war against China, home-grown companies from the manufacturing giant are now following in their footsteps. Metal Springs

To be sure, Chinese manufacturers aren’t moving all their production out of the mainland. But a combination of geopolitical risks – such as tensions with the US – and rising costs are pushing them to look for alternatives.

“We already see a lot of China-based manufacturers are actively looking at setting up overseas productions with anticipation of the supply chain challenges and political risks,” Shay Luo, a principal at consulting firm Kearney told Insider.

While India – which is set to overtake China as the most populous nation by mid-2023 – is likely to be a key beneficiary of the shift, much of the shuffle is headed to nearby Southeast Asia countries such as Vietnam, Thailand, Malaysia, and Indonesia.

Further away, lower-cost havens nearer key consuming markets – such as Mexico for the US market and Eastern Europe – are also proving popular, Luo said.

Here are the six countries these supply chains are moving to:

Bangladesh, an apparel manufacturing giant, has attracted US$770 million worth of foreign direct investment from China.

South Asian countries like India and Bangladesh are prime candidates for Chinese manufacturers to move to, thanks to their vast lands and young populations.

While India is mainly positioning itself as an alternative for international manufacturers who want to diversify away from China, it is also trying to attract Chinese companies targeting the Indian market.

Apple opens its first retail store in India

Chinese firms already operating manufacturing facilities in India include smartphone makers Oppo and Vivo, and carmaker SAIC.

Bangladesh, an apparel manufacturing giant, has attracted US$770 million worth of foreign direct investment from China – the highest amount among foreign investors, Md Sirazul Islam, the executive chairman of the Bangladesh Investment Development Authority, told the Dhaka Tribune media outlet in June 2022.

Setting up manufacturing in Bangladesh was already attractive even before the pandemic and geopolitical tensions intensified because wages in China have been going up.

The cost difference is significant – the average monthly salary of a worker in Bangladesh is around US$120, less than one-fifth of the US$670 a factory worker takes home in the southern-China manufacturing hub of Guangzhou, Mostafiz Uddin, the owner of the Bangladeshi apparel manufacturer Denim Expert, told Insider in December 2022.

Thailand is Southeast Asia’s auto manufacturing hub.

As Southeast Asia’s second-largest economy, Thailand has been moving up the value chain in manufacturing and is a production hub for car parts, vehicles, and electronics, with multinationals such as Sony and Sharp setting up shop there.

And Chinese companies aren’t too far behind either.

For instance, Chinese companies have relocated parts of their supply chains to Thailand. Companies producing solar panels, such as Shanghai’s JinkoSolar, are moving their production to the island nation to take advantage of lower costs and avoid geopolitical tensions, the South China Morning Post reported in July.

Tesla launches sales in Thailand, heating up electric vehicle competition

Chinese car-parts manufacturers are also making their way to Thailand due to pressure from their overseas clients who are now wary of relying too much on China and over geopolitical tensions, Bloomberg reported on April 11, citing car-parts suppliers.

One supplier of electric vehicle charging components identified by his family name Wang told Bloomberg he was pushed into setting up a new factory overseas by a European customer.

“It looks like I have no choice. Move out, or lose the business,” Wang told the media outlet.

Vietnam has witnessed a rash of foreign investments in its economy.

With China’s economy reopening after three years of strict COVID-19 restrictions, there has been a flood of Chinese companies setting up shop in Vietnam, Reuters reported on March 16.

“Enquiries from Chinese firms about manufacturing investment in Vietnam grew exponentially in the last quarter of last year,” Michael Chan, the senior director of leasing at industrial real estate specialist BW Industrial Development, told Reuters. Chan said the rash of influx is mostly catering to larger peers that are already there.

For instance, Vietnam’s solar panel industry – dominated by Chinese firms – is attracting ancillary support providers such as plastic moulding manufacturers, die-cast makers, and energy storage providers, per Reuters, citing industry sources.

Chinese companies that have moved to Vietnam include Growatt, a Shenzhen-based power storage firm, and Hangzhou First Applied Material, a solar panel component maker.

Mexico is shaping up to be a prime location for Chinese manufacturers to relocate – particularly since the US is a key consuming market.

“We’re increasingly seeing Chinese companies manufacturing finished goods in Mexico to serve their US customers, immunising themselves against further worsening of the US and China relations,” Kearney, the consultancy, said in its 2022 Reshoring Index report published on April 13. “In their wake, second- and third-tier Chinese suppliers are coming to Mexico to continue serving their OEM customers,” Kearney added, referring to original equipment manufacturers.

Mexico’s Hofusan Industrial Park – which was jointly developed by the Mexican Santos family, and Chinese investors Holley Group and Futong Group – represents how Chinese firms are moving closer to their key consumers by moving to a nearby country. And here are other similar industrial estates being built in Mexico right now, added Kearney.

Chinese companies exporting out of Mexico to the US would also be able to lower freight rates due to increases in energy prices. and skirt high US tariffs slapped on some products from China, per Bloomberg.

Chinese car-parts makers that supply to European auto manufacturers are also looking for factory sites overseas.

Minth, a car parts company, which is based in the eastern city of Ningbo, broke ground on a factory in Poland in September 2022.

“We’ve all seen some recent trend of reverse globalisation,” Liu Yanchun, Minth’s chief operating officer, said at an event in Shanghai in February, per Bloomberg. “We’ll have many cards to play, and will never be checkmated,” Liu added.

Shenzhen-based electric vehicle maker BYD – backed by legendary investor Warren Buffett – is planning to build its first EV factory in Europe.

Handle Springs We’re doing feasibility studies to see our plans for the future,” Stella Li, executive vice-president at BYD told Bloomberg in February. The EV maker hasn’t decided on specific countries, but announced ambitious plans to expand sales across the continent in late 2022.