In the ever-evolving landscape of modern HVAC systems, the efficiency of heat transfer technologies plays a pivotal role in optimizing energy consumption and enhancing environmental sustainability. One of the standout solutions in this arena is the Copper Tube Fin Heat Exchanger, renowned for its superior thermal conductivity and reliability. According to industry reports, systems utilizing copper tube fin configurations can achieve energy efficiency ratings up to 15% higher than traditional heat exchangers, significantly contributing to reduced operational costs for both residential and commercial applications.

The adoption of Copper Tube Fin Heat Exchangers is increasingly driven by stringent energy efficiency regulations and the growing demand for sustainable building practices. Notably, the International Energy Agency (IEA) projects that advancements in HVAC technologies, including heat exchangers, could lead to a reduction in global CO2 emissions by nearly 20% by 2030. This remarkable potential underscores the importance of understanding and implementing modern solutions that harness the advantages of copper tube fin designs, marking a significant step towards energy-efficient HVAC systems.

As we delve deeper into this comprehensive guide, we will unlock the immense potential of Copper Tube Fin Heat Exchangers, exploring their design intricacies, applications, and the latest innovations reshaping the industry. This examination not only highlights their importance in improving efficiency but also positions them as a cornerstone for future advancements in HVAC technology.

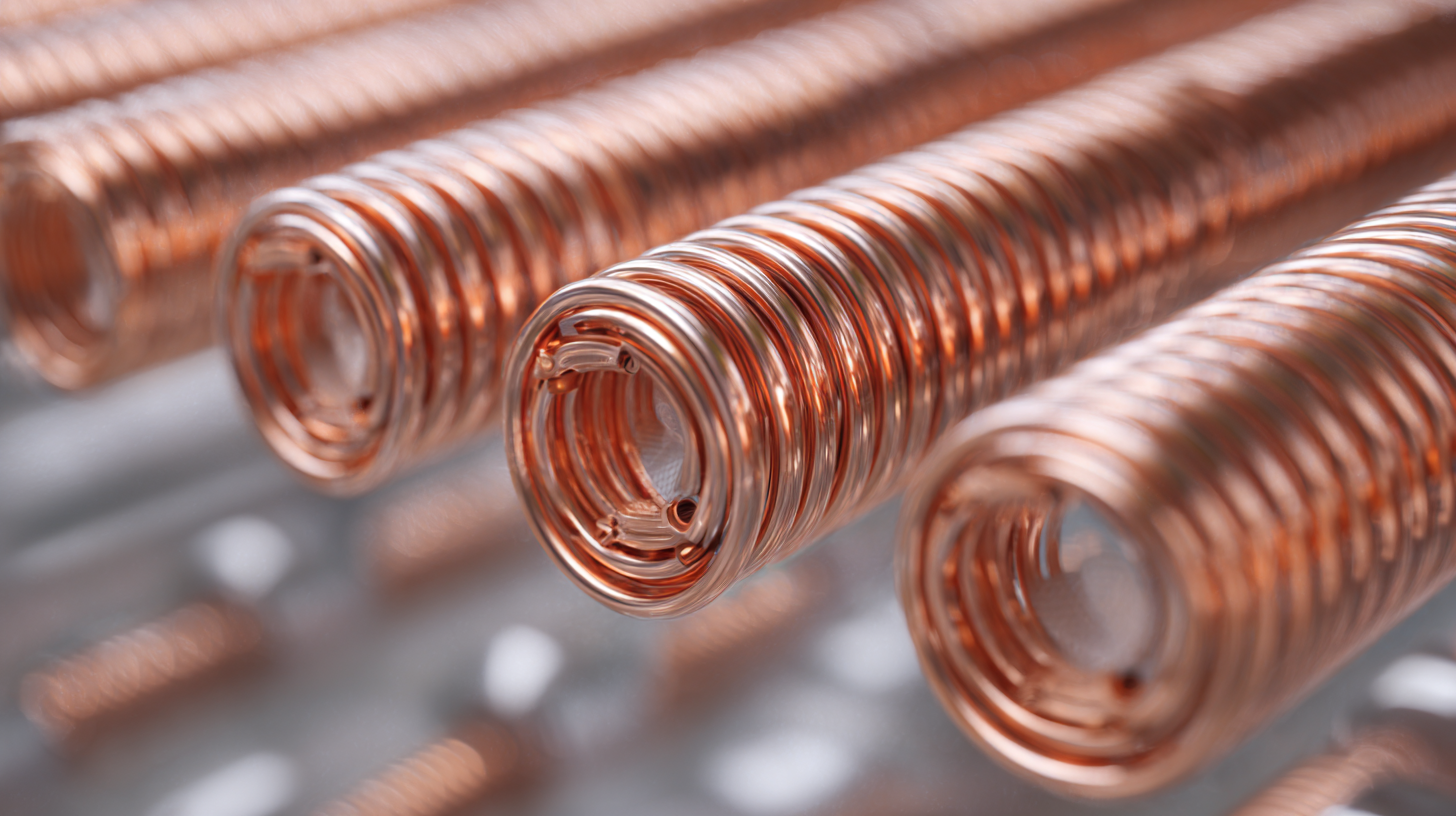

Copper tube fin heat exchangers play a crucial role in enhancing the efficiency of HVAC systems. These components are designed to maximize the surface area for heat transfer while minimizing the resistance to fluid flow, making them highly effective in heating and cooling applications. The unique properties of copper, including its excellent thermal conductivity, allow for rapid heat exchange, which is vital for maintaining optimal indoor temperatures while reducing energy consumption. This efficiency translates to lower operational costs and a smaller environmental footprint, making them an attractive choice for modern HVAC solutions.

Moreover, the integration of copper tube fin heat exchangers into HVAC systems can lead to improved performance reliability. The durability of copper prevents corrosion and degradation over time, ensuring a longer lifespan for these units compared to alternatives. Additionally, advancements in design and manufacturing techniques have led to more compact and lightweight models, further facilitating their installation and maintenance. As building codes and energy efficiency standards become increasingly stringent, the importance of using effective components like copper tube fin heat exchangers continues to rise, solidifying their position as essential elements in modern heating, ventilation, and air conditioning systems.

The thermal conductivity of copper is unrivaled, making it a cornerstone material in the construction of heat exchangers. According to a study by the Copper Development Association, copper boasts a thermal conductivity of approximately 401 W/m·K, significantly higher than other metals like aluminum (237 W/m·K) and stainless steel (16 W/m·K). This property allows copper tube fin heat exchangers to transfer heat more efficiently, ultimately improving the performance of HVAC systems. The reliability of copper, combined with its natural resistance to corrosion, ensures longevity and reduced maintenance costs, which are vital for modern applications.

When selecting materials for HVAC solutions, it’s essential to consider thermal conductivity and overall efficiency. **Tip:** Always evaluate the operating environment of the HVAC system to ensure that copper’s advantages can be fully realized, especially in high-temperature or humid conditions where other materials may fail. Moreover, the inherent antimicrobial properties of copper contribute to maintaining cleaner systems, which is a crucial aspect of HVAC hygiene.

Implementing copper tube fin heat exchangers can lead to energy savings of up to 30%, as reported by the U.S. Department of Energy. **Tip:** Regularly analyze the energy performance of your HVAC system, as optimizing it can lead to substantial savings in operational costs and enhance overall effectiveness. By harnessing the key advantages of copper, businesses can look forward to a more sustainable and efficient approach to heating and cooling solutions.

| Property | Copper Tubes | Aluminum Tubes | Steel Tubes |

|---|---|---|---|

| Thermal Conductivity (W/m·K) | 385 | 237 | 53 |

| Corrosion Resistance | Excellent | Moderate | Poor |

| Weight (kg/m) | 0.93 | 0.22 | 1.55 |

| Cost (USD per kg) | 9.50 | 5.00 | 1.80 |

| Lifespan (years) | 50+ | 20-25 | 15-20 |

Heat transfer mechanisms play a crucial role in the efficiency of modern HVAC systems, particularly when utilizing copper tube fin heat exchangers. These devices enhance the contact area between the fluid and the surrounding air, optimizing heat transfer through conduction and convection. Reports from the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) highlight that effective heat exchangers can improve energy efficiency ratings by up to 40%, offering significant cost savings in operational expenses.

In recent advancements, the use of enhanced fin designs, such as louvered and serrated fins, has further refined these heat transfer processes. Studies indicate that these modifications can increase the surface area for heat exchange by as much as 25%, allowing for greater thermal performance without significant increases in space or weight. As HVAC systems continue to evolve, the integration of innovative materials and technologies within copper tube fin heat exchangers is setting new benchmarks for energy efficiency and reliability in heating and cooling solutions.

This chart displays the heat transfer efficiency of copper tube fin heat exchangers, showcasing the impact of various factors like airflow rate, fin spacing, and heat transfer coefficient on overall performance.

When evaluating the efficiency of copper tube fin heat exchangers, two critical performance metrics stand out: the Coefficient of Performance (COP) and the Energy Efficiency Ratio (EER). The COP measures the heat output per unit of energy consumed, providing a clear picture of how effectively a heat exchanger converts energy into heating or cooling. Meanwhile, the EER focuses on the energy efficiency of the system under cooling operation, calculated by dividing the cooling capacity by the total electrical input. Understanding these metrics is essential for selecting the right HVAC solutions that lead to energy savings and optimal performance.

Tips for enhancing the performance of copper tube fin heat exchangers include regular maintenance checks and ensuring that the system is properly sized for the intended application. An oversized unit can lead to inefficiencies and increased wear, while an undersized unit may struggle to meet demand. Additionally, optimizing airflow and ensuring clean components can significantly improve the COP and EER, ultimately leading to lower operational costs and better thermal comfort. By focusing on these metrics and tips, HVAC professionals can unlock the full potential of copper tube fin heat exchangers in modern applications.

The landscape of HVAC technology is evolving rapidly, and copper tube fin heat exchangers are at the forefront of these advancements. As energy efficiency becomes a primary concern for both consumers and manufacturers, innovations in design are paving the way for better thermal performance and reduced operational costs. According to a recent report by the International Energy Agency (IEA), heat exchanger technology improvements could lead to energy savings of up to 30% in HVAC systems, underscoring the significance of staying updated on modern developments.

Future trends indicate a growing focus on smart HVAC solutions, which integrate IoT technologies to optimize system performance. This convergence of smart tools and heat exchanger technology allows for real-time monitoring and predictive maintenance, driving efficiency even further. Industry leaders project that by 2025, over 50% of HVAC systems will incorporate advanced control mechanisms, enabling dynamic adaptations based on user demand and environmental conditions.

Tips: When considering upgrading your HVAC system, look for models that feature innovative copper tube fin heat exchangers with enhanced energy efficiency ratings. Additionally, ensure that you invest in smart controls that can monitor system performance and provide analytics for maintenance scheduling. Embracing these technologies not only aids in reducing energy consumption but also enhances the lifespan of your HVAC system.

C systems?

Copper has unrivaled thermal conductivity (approximately 401 W/m·K), significantly higher than materials like aluminum and stainless steel, which allows for more efficient heat transfer and improved HVAC system performance.

The use of copper tube fin heat exchangers can lead to energy savings of up to 30%, significantly reducing operational costs while enhancing overall system effectiveness.

Copper’s natural resistance to corrosion and degradation ensures a longer lifespan for heat exchangers, resulting in reduced maintenance costs compared to alternative materials.

Enhanced fin designs, such as louvered and serrated fins, increase the surface area for heat exchange by up to 25%, improving thermal performance without adding significant weight or size.

It is crucial to assess the operating environment to fully utilize the advantages of copper, especially in extreme conditions like high temperatures or humidity, where other materials may fail.

The inherent antimicrobial properties of copper contribute to maintaining cleaner systems, which is essential for the hygiene of HVAC applications.

As these regulations become stricter, the role of effective components like copper tube fin heat exchangers becomes increasingly important in meeting performance and efficiency requirements in HVAC systems.

Efficient heat transfer mechanisms, facilitated by copper tube fin heat exchangers, improve the contact area between working fluids and surrounding air, optimizing energy efficiency ratings and leading to substantial cost savings.

Integrating innovative materials and technologies within copper tube fin heat exchangers sets new benchmarks for energy efficiency and reliability, supporting the evolution of modern heating and cooling solutions.

The article "Unlocking the Efficiency of Copper Tube Fin Heat Exchangers: A Comprehensive Guide to Modern HVAC Solutions" delves into the critical role that Copper Tube Fin Heat Exchangers play in enhancing HVAC efficiency. It highlights the superior thermal conductivity and reliability of copper materials, which significantly contribute to the overall performance of modern heating and cooling systems.

Furthermore, the article explores the intricate heat transfer mechanisms utilized in these exchangers, specifically examining performance metrics such as Coefficient of Performance (COP) and Energy Efficiency Ratio (EER). Emphasizing future trends, it discusses innovations in Copper Tube Fin Heat Exchanger technology that promise to further optimize energy efficiency and reliability in HVAC applications, indicating a progressive shift towards more sustainable cooling and heating solutions.