Humans are funny creatures. For whatever reason, when handling a piece of electronics, we tend to equate heft with value. If something feels too light, it gives the impression of being cheap or inferior. As such, it’s not unheard of for gadgets to include a little chunk of metal that serves no purpose other than to add weight.

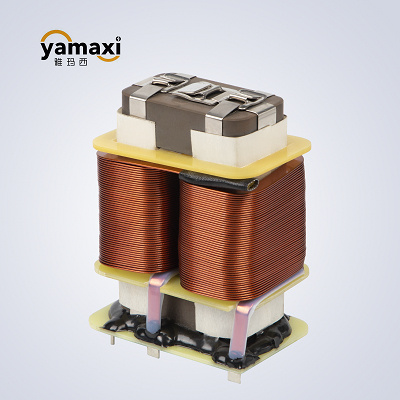

But a recent discovery by the aptly named [RedditCringe990] really takes things to a new low. Upon opening up the cheap power supply that came with their computer case, they noticed an odd little box that didn’t appear to have any electrical connection to the rest of the device. After unscrewing it from the metal body of the power supply and pulling the bottom panel off, they found it was packed full of iron filings. Partial Potting Transformer

At some level, you have to appreciate the attention to detail here. At first glance, especially if you were peeking through the PSU’s air vents, you could be forgiven for thinking the box was some kind of transformer. It’s even got some alphanumeric gibberish written on the side to help complete the look. Makes us wonder how many of these things might actually have gone undetected by less curious PC-builders.

As you might expect, the weighted box is only one of the issues with this particular PSU. As pointed out by fellow Redditor [Hattix], even the functional components are worthy of suspicion. There’s no protection on the input or output, no safety capacitor, and (unsurprisingly) no regulatory marks.

We’d say the thing might still be useful as a boat anchor, but now that the box of iron fillings has been removed, it’s probably not even heavy enough. Stay safe out there, folks.

To be honest I am surprised they used something as expensive as iron filings, and not just dirt. This is nothing new though. I recall the old Compaq computers weighed a ton and if someone started with one of those beasts and moved to a more “common” computer they were like where is the weight. You take the lid off one of those old beasts and, there is the weight, just a heavy steel case. I often joke about that as most people did not use desktop computers as step stools. One company I worked for had phones that looked like good ol desktop touch tone phones but if you took one apart, there was a big old hunk of metal bolted to the base and the “phone” was a PCB that was not much bigger than the touchtone pad. The things would have felt hollow and not sat on your desk if you pulled at all on the cord without the extra weight.

Its probably ground up slag from a waste pile.

Sometimes what we would see as excess weight now isn’t a bad thing, and at the time absolutely makes sense. Which with the early days of computers I’d say applies quite well.

Take the IBM Model M keyboard for instance – when it was new it was stupendously expensive and even if you built it more inline with modern save every penny hyper mass produced styles (of reasonable quality product for a somewhat fair comparison) at the time it would still have been very expensive – might even work out more so as you won’t be selling that many keyboards. Expensive no matter what you do, enough so it will get repaired rather than replaced should it ever go wrong – So you build it tougher than it needs to be, and probably make sure its more repairable as doesn’t cost a meaningful amount if any more in production but gives your certainty your products will not ruin your brand.

Now with how well established the high quality keyboard market is, how many proven enduring lighter builds, cheaper lightweight materials and much much cheaper setting up of complex multi-stage mass production lines something as overbuilt as the Model M wouldn’t come from a company with any meaningful R&D budget – they would be looking to shave every penny of each keyboard so much more because they know they will sell a great many of them – it has become worth that doubling of the R&D and tooling budget now to make a less overbuilt, lighter and cheaper per unit product even if they keep the effective quality much the same.

They wouldn’t want to risk customs X-rays picking up organic material. I’m sure there are plenty of iron filings in the factories that make the metal components. Shipping them off inside products saves disposing of them.

And Detroit pumped their air pollution into the tires of the cars they were building. B^)

maybe it’s an iron-based memory, a la e. coli.

The German word for an emotional and indeterminate experience of the appearance of something is Anmutung.

https://de.wikipedia.org/wiki/Anmutung

My favorite part is the “cooling fan” brand of… cooling fan. Very on-point marketing for “cooling fan” so it makes sense they are such a recognizable manufacturer of consumer goods.

I need a faster PSU, you know one with a lower weight state.

All those iron would literally release a firework if it was suddenly spilled over the working PSU PCB. Planned obsolescence, probably ^_^

This thing is muntzing in it’s purest form. There used to be a coil in there as a passive PFC, there even is a connector for it on the PCB labeled “PFC”. They just omitted it and replaced it with a wire-link … just as the rest of the input filter circuitry by the way. IT’s all gone. This thing must be a EMI disaster.

Yes, that is the most likely reason. This box is a PFC choke dummy. In earlier times these chokes were quite large and heavy. Later they were replaced by a much smaller choke thanks to active PFC circuits.

I suspect it is shielding. Is it near a floppy or a CRT? I have seen prototype desktops that worked just fine. When we lined them up beside each other they all had drive failures except the one on the left end. A piece of steel or mu-metal in the housing near a flyback transformer fixed it. Iron (steel?) filings have better properties for some things.

I doubt that, it’d be far cheaper to just add a piece of shielding.

This is just to make you or someone else think you got a better PSU by faking what looks like a PFC choke.

You’re way too charitable. It’s not shielding, it’s obviously ballast to disguise a cheap product, and if you take apart Chinese power supplies you will have seen plenty before. I’ve seen bits of cement or pots of sand epoxied to the inside of the case. It happens.

Hey, at least there’s a fuse! :-3

True. But it’s in the inside? Shouldn’t it be located in a little fuse holder accessible on the outside? Ordinary people aren’t supposed to open power supplies, after all.

What’s also strange: Those big caps are merely rated 330uF and 200v. Shouldn’t they be 470uF and 500v? The installed ones can barely handle 220v AC. 🤔

None of the switchmodePSUs I’ve ever worked on have user replaceable fuses. A fuse in a switchmode PSU is a last resort to prevent fire in case of a severe and unrecoverable failure. Other events such as a short on the output or overload are handled electronically.

And 200V capacitors are okay, because in the half bridge configuration they only see half of the mains voltage anyway (they are in series)

Hmm, so you think it’s for the Chinese market? Since they have 220v I think (checked, I was wrong) and not many other places do these days. 230v in the EU 240v in the UK and 120 in the US right? Or maybe south America? Do they have 220v? I see Brazil and Mexico(industrial) use 220v, as well as Saudi Arabia(industrial). So basically only Brazil has 220v in more general use. I would assume that if the caps are 200v it’s for areas with a voltage in the hundred range. “Japan, Taiwan, Saudi Arabia, North America, Central America and some parts of northern South America use a voltage between 100 V and 127 V”

Makes it weird that you see devices on Chinese sites for either 110 or 220, as if we live many decades in the past. Even when it’s rated 230 they will list it as 220, weird.

Why not just get a bag of quick dry cement to fix it? I mean epoxy and welding? What?

… as in your computer’s PCB traces if those iron fillings ever get loose inside your computer and cause random shorts.

Dummy components are bad enough when they don’t add an unnecessary mode of failure but this is ridiculous.

And Beats Headphones are still popular. Add to much bass to trashy drivers. Then add pointless weight which is worth 800% of the headphones apparently. Buy buy buy sheep.

Back in the 70’s and 80’s, Motorola pulled a similar stunt with their two-way radio equipment. The sales people would make it a point to demonstrate how much heavier Motorola’s microphones were compared to the competition, implying that weight = durability. I’m sure a lot of public service agencies were convinced to buy Motorola radios based on this scam. So why were they heavier? Because Motorola attached a big steel weight inside the microphone case. Take that weight out and their mics were no heavier than any other manufacturer.

Still better than the crap Kenwood is selling.

Motorola- You can get better but can’t pay more.

Yeah, cheap, flimsy Kenwood crap, you can tell it’s garbage compared to Motorola because look how little it weighs compared to this solid, heavy duty Moto mic…

I pulled the weight out of my Yaesu 817 mic, since I would be carrying it while hiking, but to be honest, now it feels like a plastic toy instead, so for non portable use, I still use a weighted mic

I worked for Motorola back in the 80s when they sold most of the radios for police dispatch. Their portable radios, MX series, were used by most of the police in the US. I remember visiting a customer in the LA area once and their service tech told me the police often used the radios as a club. He said he frequently had to clean blood, skin, and hair out of the nooks and crannies of the radios.

Motorola mics use an internal ALUMINUM casting for ruggedizing and to which the clip or metal disc for mounting is attached.

The idea that weight connotes quality is a very durable holdover from the days when the size and heft of the transformers in vacuum tube equipment meant everything. Lots of people still hang on to that, and most probably don’t even know why.

This is a popular way to run a broadband, unlicensed radio transmitter.

https://electronics.stackexchange.com/questions/306371/what-is-this-transformer-like-component-and-why-is-it-not-really-connected http://web.archive.org/web /20120506065944/http://www.hardwaresecrets.com/blog/Hantol-PSU-Fake-PFC-Made-of-cement/220 http://electricstuff.co.uk/acadapter.html

I’ve done this. Added some lead free car tire wheel weights to a 3d printed macro pad for added weight. Thing was sliding around the desk without it.

I’ve had luck pausing a print before the upper layers are done and filling the infill with some sand as ballast. Plus you can kind of use it as a maraca, which is fun

That’s not new, I believe. I heard that companies like R+S did install lead plates in their pricey equipment. To make it look more professional and worthy. That was done when miniaturization in electronics was making equipment lighter than it used to be. So lead plates were installed, to make everything feel massive again.

From China, the country of nutrient free baby formula. At least that guy was executed, but only because he attracted so much negative attention in China AND internationally. Criminals who don’t attract such attention are given a pass as long as they bring in foreign currencies and don’t cross the CCP.

There is a use for arbitrarily making something heavier but only if the thing shouldn’t move around on a desktop or something. Like a telephone (remember those?), maybe even a calculator (geez remember those). Actual anything that has buttons and gets used so like my oscilloscope would be nice to not have it sliding around. Older stuff used to be heavy enough but modern equipment is usually light. The AWG I have is basically an empty plastic box with a tiny circuit board in it. I have to strap it down to use.

No joke! I have a cheapish Amazon function generator that weighs about as much as an Altoids tin and slides all over my desk. It needs a pound or two of ballast to feel right.

I like how the box is shaped like a tiny dumpster.

My wife got a few inexpensive imported lamps, they have pretty shades on them and the bases look nice, even though they are tin covers over a slug of cement. The problem with them is twofold, one is it is crappy cement that tends to crack and crumble, and the other big one is they seem to not let it dry all the way, so years down the line you find the lamp at an angle and think, oh the nut at the bottom is lose and when you pick it up big chunks of what used to be the cement in the base fall out because they have dried out and cracked. One of these days I am going to work out how to hold the base in the center of an old 25 pound iron weight I picked up from a set roadside. This could involve welding something to the weight but to be honest I think the first pass is going to involve getting it propped up nice and filling the hole with epoxy.

Got a 3 ton winch from norways equvelent of harbor freight (Biltema), which failed in «winch in» state and pulled my car over a 9 foot drop. When I opened the controller handle it was filled with iron scraps to give it weight, but some had gotten loose an fused the terminals of the the “winch in” button….. tried to confront them but they claimed I had filled the controller and refused any responsibility…

I had similar mouse pad in the picture and it is a much better sturdy build than the psu

Old supplies had passive PFC chokes bolted on the box, exactly where this thing is. Remember those simple FSP 350, 400W supplies which only needed to drop some fresh capacitors once in a while to run indefinitely. New supplies have powerful transformers and cooling, so they are heavier.

If i were those chinese, i would run the input leads through this weight thing, pot it in epoxy, and no one would guess a thing, unless using an oscilloscope or inductance meter on it.

Please be kind and respectful to help make the comments section excellent. (Comment Policy)

This site uses Akismet to reduce spam. Learn how your comment data is processed.

High Voltage Inductor By using our website and services, you expressly agree to the placement of our performance, functionality and advertising cookies. Learn more