ORCHARD PARK, N.Y. – Plastics industry veterans Benjamin Harp and Tom Rybicki have launched Polymer Medical Inc. to provide healthcare and biosciences clients with contract injection-molding and assembly services. The new company’s focus will be producing critical drug-delivery systems, medical disposables like syringes, medical devices for home healthcare to orthopedics, specialty packaging, and pharmaceutical disposables among other services. Harp and Rybicki each have decades of experience founding and operating plastics industry manufacturers for healthcare, pharmaceuticals, and nutraceuticals.

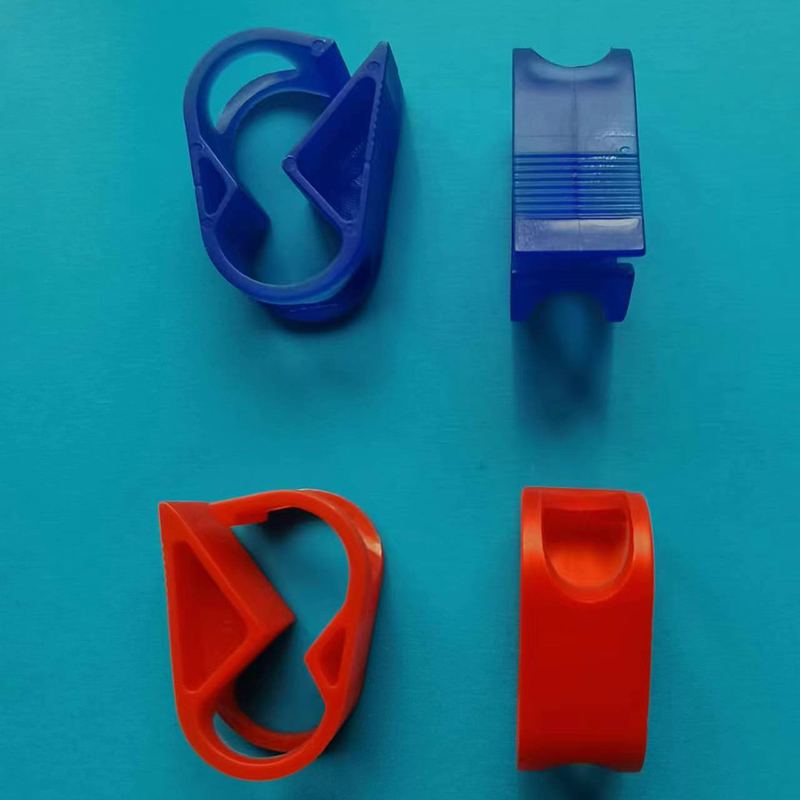

“There’s a rising demand for medical devices partly because of changes in demographics and approaches to home healthcare; the time is right for a new entrant like Polymer Medical,” says Harp, president of Polymer Medical. “Our knowledge of the specifications and science of producing polymers for healthcare and bioscience along with what we understand about delivering product quality and innovation give us a competitive edge.” Medical Respiratory Mould

Polymer Medical Vice President of Operations Tom Rybicki (left) and President Benjamin Harp stand in one of the soon-to-be-equipped certified ISO cleanrooms of Polymer Medical’s manufacturing facility. [Photo courtesy of Polymer Medical]

According to an array of analyst reports, researchers expect the medical polymers market to grow at a compound annual growth rate of more than five percent through 2030, reaching more than $30 billion. Harp and Rybicki also believe North American customers are more eager than before the pandemic to favor U.S.-based providers for their supply chain. The field is already packed with competition, but Harp and Rybicki see Polymer Medical’s creativity, design know-how, process control, and tooling expertise as critical differentiators.

“When a client comes to us, we’ll provide Design for Manufacturing analysis to offer ways to improve on what they’re already trusting us to make,” adds Rybicki, vice president of Operations for Polymer Medical. “When we take an order from a customer, we assess their tool, or mold, for those big or small things that could disrupt production. That saves money for the customer and ensures quality.”

Quality is a centerpiece for Polymer Medical, which is why Harp says the new company has invested in its quality management systems, in part, to meet ISO 13485:2016 standards for medical devices. After analysis by Polymer Medical’s degreed engineers and RJG Master Molder® qualified technicians and managers, Harp’s employees will produce customers’ designs in ISO-7 and ISO-8 clean manufacturing environments. The company also provides cleanroom assembly and packaging.

“Tom and I have more than 50 years of experience,” Harp adds. “The decision to found Polymer Medical was done after careful consideration of the landscape and market opportunity; we will raise the level of competition and quality for customers.”

Polymer Medical’s newly refurbished plant is at 168 Thorn Ave., Orchard Park, N.Y.

Orchard Park, N.Y.-based Polymer Medical is a world-class provider of contract plastic injection molding and assembly for healthcare and biosciences. Its services include in-house tool building, tool transfer, product enhancement, and finished medical device assembly. For more information, visit https://polymermedical.com/

The opinions expressed in this news release are the author’s only and do not necessarily reflect those of Medical Design & Outsourcing or its employees.

Subscribe to Medical Design & Outsourcing. Bookmark, share and interact with the leading medical design engineering magazine today.

DeviceTalks is a conversation among medical technology leaders. It's events, podcasts, webinars and one-on-one exchanges of ideas & insights.

The Medical Device Business Journal. MassDevice is the leading medical device news business journal telling the stories of the devices that save lives.

Plastic Injection Molding Medical Parts Copyright © 2024 WTWH Media, LLC. All Rights Reserved. The material on this site may not be reproduced, distributed, transmitted, cached or otherwise used, except with the prior written permission of WTWH Media LLC. Site Map | Privacy Policy | RSS