Standards are in place to ensure that extruded plastic pipes for underground cables offer appropriate protection from environmental damage. Among other parameters, the standards specify the diameter/wall-thickness ratio of a material per running meter of pipe. To reduce cost, recyclates or inferior quality materials may be used, but the property profile and processing characteristics are highly dependent on the batch. Another way to reduce cost is to physically foam the pipes by injecting gases such as carbon dioxide or nitrogen into the plastic prior to extrusion. During the pipe extrusion process, the gases form a fine-pored foam. Less plastic is consumed through this lightweighting technique, resulting in lower material costs. In a joint project, Hans Weber Maschinenfabrik GmbH and Promix Solutions AG have evaluated the feasibility, practicality, and savings potential of physical foaming.

Weber supplied a grooved barrel extruder type NE7.40 for the foamed middle layer and a grooved barrel extruder type NE5.40 for the inner and outer layers. A Weber PKM250 three-layer pipe head was used as the die. Based in Kronach, Germany, Weber is an almost 100-year-old family-run company steeped in mechanical engineering expertise. Its wide-ranging portfolio includes extrusion technology products, wood and metal grinding equipment, gantry systems, and robotics. Multi Lumen Medical Tubing

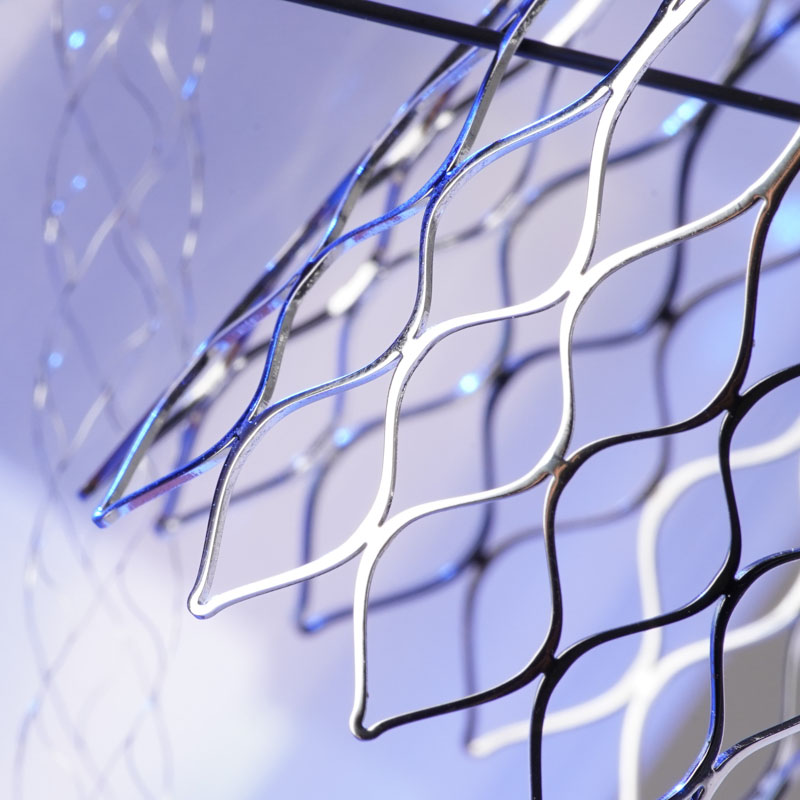

Promix Solutions, a supplier of mixing, foaming, and cooling products for plastics processing based in Winterthur, Switzerland, provided an N400 gas dosing station with adapted injector for precise metering of the nitrogen and a P1 180 melt cooler for homogenization and temperature reduction of the melt. In the initial trials, Borealis' HDPE HE3490 LS was used for a DN 110 x 6.3 cable protection tube foamed with nitrogen.

Foamed cable-protection pipes use up to 26 % less virgin polymer than conventional products.

Following production of a non-foamed reference sample, the metered gas quantity was gradually increased, resulting in a weight reduction of up to 26% of virgin material and approximately 15% of recycled material. Tested in accordance with DIN 16876 and Swiss standard GA KSR 2010, the pipe met all requirements. Particular attention was paid to the ring stiffness and drop test according to DIN EN 744, said Promix. Based on the positive results, the test was repeated with a foamed inner layer made of recycled HDPE, which also showed good feasibility with a stable process.

Given the double whammy of material shortages and elevated resin prices, microcellular foaming of plastic pipes provides extruders with an opportunity to save on material costs while reducing their product’s carbon footprint. Unlike processes that rely on exothermic chemical blowing agents, the foaming technique described here does not use any substances considered to be of very high concern. Additives accumulated through regrind recycling also are avoided.

This technology can be applied to other extruded pipe products, noted the companies.

In the months ahead, Weber and Promix will continue conducting tests on the viability of this foaming technique on other types of pipes and polymers. They also are currently working on a solution for physically foamed PVC extrudates.

Editor in chief of PlasticsToday since 2015, Norbert Sparrow has more than 30 years of editorial experience in business-to-business media. He studied journalism at the Centre Universitaire d'Etudes du Journalisme in Strasbourg, France, where he earned a master's degree. Reach him at [email protected].

Shibaura Debuts Medical Molding Machine at Plastec West

Plastic or Paper? A Nuanced Sustainability Story

California Legislators Want to Ban Plastic Bags. Period.

Polymer Tube Extrusion Copyright © 2024 All rights reserved. Informa Markets, a trading division of Informa PLC.