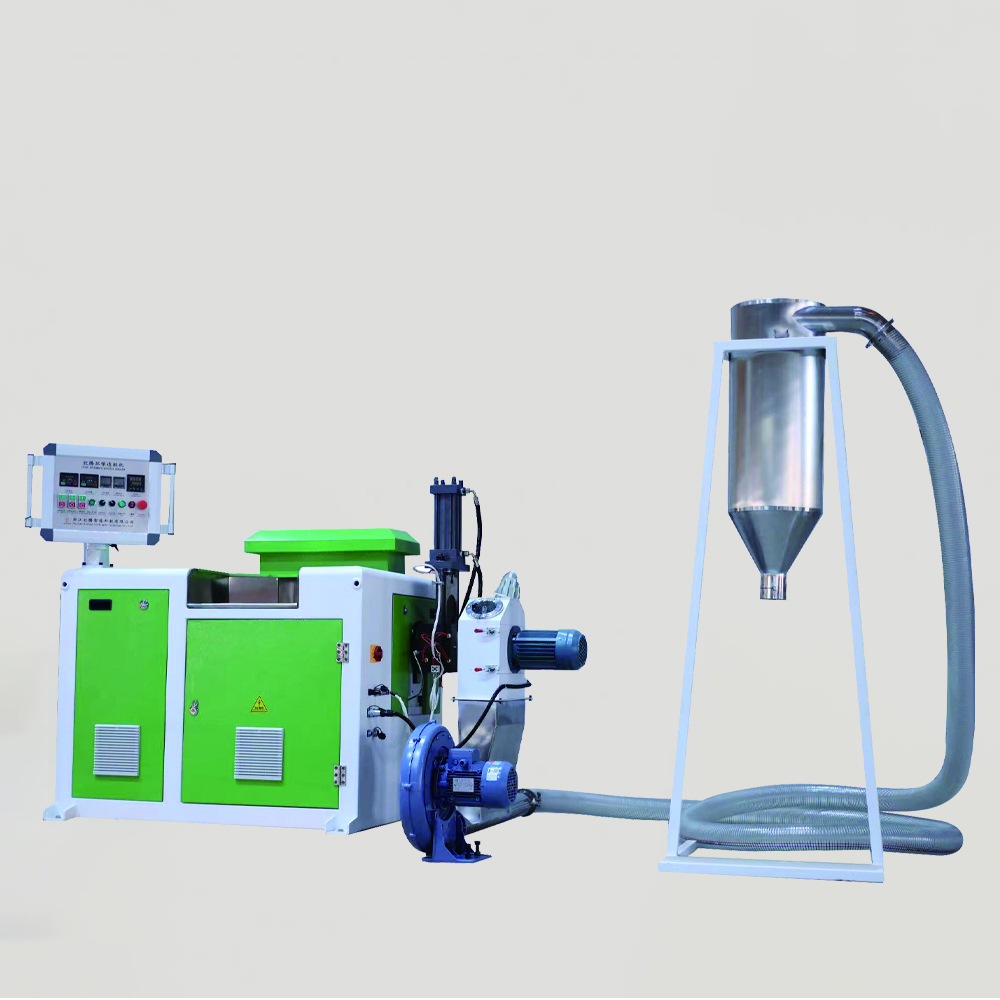

A ZSE-50 mm HSEI twin-screw extruder.

Segmented screw elements on high-torque splined shafts. Pe Bimetallic Screw Barrel

An HSEI process section with modular barrels and screws. An example of a co-rotating, intermeshing HSEI twin-screw set.

W hile recently reading The Wisdom of Crowds by James Surowiecki, which describes the proven benefits of collective wisdom, my mind started to wander as to how this concept might benefit the extrusion industry. I reflected upon my aversion/appreciation regarding using formulas to demystify the twin-screw extrusion process and felt that perhaps some others might share this trait. When I started in the plastics industry more than 20 years ago (I got the job at Killion Extruders because I mowed Jack Killion?s mother?s lawn) I had very little understanding of how an extruder worked. What I?ve learned since is that starting with the basics can get you a long way, and reaching out to industry experts for help is invaluable. The goal of this article is to provide some basic insights into twin-screw extrusion technology. In attempting to do so I followed my own advice by asking experts for their help: Paul Anderson (Coperion), Bill Thiele (Leistritz, retired), and David Todd (Polymer Processing Institute, retired). Bert Elliott, Leistritz Engineering Manager, also assisted. Specifically, I requested that they define a few simple equations that were important for anyone involved with a twin-screw extrusion manufacturing operation. The following reflects their feedback. Twin-screw Extruder Overview Twin-screw extruders have historically been used to produce pellets to enable consistent feeding into a secondary processing device, such as an injection molding machine or single-screw extruder. There is also a fast growing trend to bypass the pelletizing step and to produce a film, fiber, sheet, or profile from the twin-screw extruder. This is referred to as direct extrusion. Regardless of the end product, the operations performed in the twin-screw extruder are identical. There are two distinct families of twin-screw extruders, defined as low-speed late fusion (LSLF) twin-screw extruders (run up to 50 rpm), and high-speed energy input (HSEI) twin-screw extruders (run up to 1200+ rpm). HSEI twin-screw extruders are primarily used for compounding, reactive processing, and/or devolatilization. By contrast, LSLF counterrotating twin-screw extruders are designed to mix at low shear and pump at uniform pressures for PVC and similar processes. These devices are often inadequate to perform energy-intensive processing. This article is targeted to the HSEI type of twin-screw extruder. The co-rotating intermeshing twin-screw extruder dominates this market, however counterrotating intermeshing and non-intermeshing twin-screw extruders are also used for specialty applications. HSEI twin-screw extruders process materials bounded by screw flights and barrel walls. Screws are segmented and assembled on high-torque splined/hammered shafts that allow the maximum torque to be applied to the process. Screw speeds are available to 1200+ rpm. A typical process length to diameter ratio (L/D) is 32:1 to 48:1, with up to 60:1 being possible. Barrels are modular, and use liquid cooling. The motor puts energy into the process via rotating screws that impart shear into the materials. Control parameters include screw speed (rpm), feed rate, process section temperatures, and vacuum level (for venting). Typical readouts are melt pressure, melt temperature, and motor amperage (torque). Segmented screws/barrels, combined with the controlled pumping and wiping characteristics of the HSEI twin-screw extruder, allows screw and barrel geometries to be matched to the process. Solids conveying and plastication occurs in the first 1?3 of the process section. Screw elements for mixing and devolatilation are applied as dictated by the process. Discharge elements build and stabilize pressure to a die. Screw designs can be shear intensive or passive. HSEI twin-screw extruders are starve fed with the output rate determined by the feeder(s). Feeders meter solids (pellets/fillers, and so on) or liquids into the HSEI twin-screw extruder. The extruder screw rpm is independent from the feed rate and is used to optimize compounding efficiencies. Because the pressure gradient is zero for much of the process, materials can be introduced into downstream barrel sections, typically by a twin-screw side stuffer that ?pushes? materials into the extruder screws. Downstream side stuffing can be beneficial to obtain high filler loadings, to decrease the abrasive wear in the extruder process section, and when processing shear-sensitive materials. The controlled pressure profile also facilitates venting. The HSEI twin-screw extruder is often mated to a filtration device and then to a pelletizing system or another die/downstream system to produce a sheet, film, fiber, or profile. Various control architectures are available based upon budget, data acquisition, and level of automation requirements. Ask the Experts As usual, when I reached out to friends and colleagues in the industry they were quick to offer help. Curiously, there were some commonalities with the formulas provided, as well as some marked differences. The following are the formulas that came back, somewhat in weighted value order: 1. Specific energy Specific energy is the amount of power that is being input by the motor into each kilogram of material being processed. This is calculated in two steps: 1) Applied power: kW (applied)=kW (motor rating) x %torque x rpm running/max. rpm x .97 (gearbox efficiency) 2) Now we can calculate the specific energy (SE): Specific energy= kW (applied)/kg per hr

SE is denoted in kW per kg/hr,

kW=kilowatts (the motor rating, kW = hp x .746),

%torque=% used of the maximum allowable torque

For example: A 40-mm twin-screw extruder is processing a mineral-filled PP at 160 kg/hr, running at 400 rpm with a %torque of 68%. The machine has a 56 kW (approx. 75 hp) motor and a maximum possible screw rpm of 600. kW (applied)=56 kW x .68 x 400/600 x .97=.154 kW per kg/hr. A lower SE indicates that less mechanical energy is being used, and a larger SE indicates more energy. It is important that SE records be maintained, particularly for troubleshooting. For instance, if a product always runs with a SE of around .25 and suddenly changes to .16, and the machine hardware and process conditions are the same, this would imply that the feedstock has changed. SE can be used when comparing materials produced by different size HSEI twin-screw extruders or even different manufacturing technologies. SE can also help define future machine configurations. For instance, if a process only draws 30-40% motor load, then a smaller motor could be specified on the next machine. 2. Percentage torque This formula indicates percentage of available rotational force being used in a process, and is a typical readout in the control panel either as a % or in amp. This is calculated as follows: %torque=applied torque (amp)/maximum available torque (amp)

Amps=electrical current or load from the main motor.

For example: If an HSEI has a maximum rating of 500A and a process draws 400 amps then the torque is 80% (400A/500A): %torque=400/500=80% Depending on the installation, the maximum available power may be limited by the extruder screw shafts (most typical), gearbox (for older machines) or the installed drive motor (if it is undersized with respect to the gearbox). At close to a 100% value failsafe logic is implemented to adjust the drive to prevent the mechanical safety clutch from disengaging or, in the worst case, to prevent screw shaft/gearbox damage. 3. Scale-up Scale-up is useful for estimating rates for production twin-screw extruders based on lab experiments. The geometries for the two extruders should be nearly identical for this equation to be valid. For processes that scale-up volumetrically, the power-based scale-up formula is as follows: Q target =Q reference x [(OD target )/OD reference )] 3

Q=throughput rate (in any units),

OD=screw outside diameter (each).

For example: A 27-mm twin-screw extruder is producing 100 kg/hr and the process is not limited by heat transfer or devolatilization factors. To estimate how much a 75-mm twin-screw extruder will produce, the following calculations will apply: Q (75 mm)=100 x (75/27) 3 Q (75 mm)=100 x 2.783= 2148 kg/hr Note: The greater difference in extruder sizes, the less reliable this calculation becomes. For a heat transfer limited process, the exponent is closer to 2. For devolatilization processes, the scale up exponent is typically between 2.3 and 2.7. Experience should play a factor with regard to the exponent utilized based upon how the specific processes scale in a facility or plant-to-plant. Advanced formulas and computer modeling approaches are also available for more intensive scale-up work. 4. Shaft torque as it relates to screw rpm The cross-sectional area of the screw shafts, the shaft design/metallurgy, and the manufacturing method determines the available torque that can be imparted into a process and dictates which motor/gearbox can integrated into the machine design. This formula helps determine the proper gearbox ratio for a new HSEI twin-screw extruder: Torque=9550 x kW/top rpm of the machine

Torque=total torque for both screw shafts, denoted in Newton-meters (N-m),

kW=motor rating on the HSEI twin-screw extruder.

For example: If a HSEI twin-screw extruder with a 60-mm screw diameter has a torque rating of 2800 N-m and uses a 200-kW motor if geared for 600 rpm, then a 400-kW motor would be specified at 1200 rpm as indicated below: 2800 = (9550 x 200)/600 2800 = (9550 x 400)/1200 For processes that operate between 0-600 rpm there is no difference whether a 200-kW (if geared for 600 rpm) or 400-kW drive was used except that the larger motor/drive costs more. Therefore, if the process doesn?t benefit from higher screw speeds, the higher kW/rpm configuration probably should not be specified. Sometimes the choice is between an HSEI twin-screw extruder with a larger screw diameter operating at lower rpm, or a smaller machine operating at a higher rpm. The cost differential for both should be compared before the final selection is made, particularly for larger machines. 5. Specific volume Specific volume (SV) represents the approximate volume per screw outside diameter (OD) length of screws for traditional Erdmenger-type screw geometries. This calculation, which is useful in a number of other formulas, allows you to calculate the volume in the process section. SV is calculated as follows: Specific volume=.94 x (OD2-ID2) x OD/1000

SV is denoted in cc/diameter of length (it?s always best to obtain SV data from the machine supplier, if possible),

OD=Screw outside diameter (each),

ID=Screw inside diameter (each).

For example: For a HSEI twin-screw extruder with a screw OD of 50 and an ID of 32 the SV is as follows: SV=.94 x (50 2 -32 2 ) x 50/1000 = 73.8 cc/dia This number can also be used for rough scaling between different size machines that share geometric similarities (OD/ID ratio) and that are not too dramatically different in size. For instance: Q target =Q reference x (volume target /volume reference ) For example, if a 45-mm twin-screw extruder has a SV of 60 cc/dia and is running at 150 kg/hr then it can be inferred that a 75-mm extruder with a SV of 240 cc/dia will process approximately four times the rate: Q target (75 mm) = 150 x (240/60)=600 kg/hr 6. Fill % approximation This formula provides the percentage of the available volume in the process section that is being utilized in the starved-fed HSEI twin-screw extruder. This calculation is useful to approximate a starting point as to where to run a process. The following formula can be used: % fill = (Q x .2777)/(SV x rpm/60) x (SG x Ef)

Q=Flow rate in kg/hr,

Ef=Average forwarding efficiency (approx. 35% for a screw with 1?3 kneaders and 2?3 flighted elements, or .35),

SV=Specific volume of extruder in cc/dia,

SG=Specific gravity of the material being processed.

For example, a 40-mm extruder with an SV of 34.8 cc/dia is running 50 kg/hr at 200 rpm: % fill = (50 x .2777)/[34.8 x (200/60)] x 1 x .35= .34, or 34% filled This formula is a very rough estimation and is meant to provide some insight into the dynamics of a starved process section. More advanced/accurate calculations take into account the specific screw geometries, the viscosity of the melt, and the degree of screw fill. This calculation might show that devolatilization intensive processes run at 30% (or less) screw fill because a highly starved process section increases the surface area of the melt pools under the vent. Another example could demonstrate that similar masterbatch formulations for film/fiber applications utilize a 40% volume, compared to 60% for injection molding applications, because of the comparative dispersive mixing requirements. Higher fill levels result in a tighter residence time distribution (RTD) and less shear, and lower fill levels are associated with wider RTD and more shear. Fill level approximations help explain why different processes benefit from comparative fill level percentages. 7. Residence time This formula provides the approximate residence time (RT) in the process section of an HSEI twin-screw extruder. As denoted above, the residence time distribution is highly dependent upon the degree of screw fill. The following formula can be used for RT: RT(sec) = (SV x SG x L/D x %fill)/(Q x .2777)

RT=Residence time in seconds,

SV=Specific volume in cc/dia,

L/D=L/D extruder ratio,

%fill=Degree of fill, expressed as a decimal (i.e. 40% = .4),

Q=kg/hr being processed.

For example, a 50-mm extruder with a SV of 70 cc/dia and 48 L/D, is running a material with a 1.1 SG at 270 kg/hr with an assumed 40% screw fill (.4), the following applies: RT = (70cc/dia x 1.1 x 48 x .4)/(270 x .2777) RT = 19.7 seconds The RT formula provides insight as to how long materials are exposed to heat and shear in the process section. 8. Specific throughput The specific throughput (ST) provides the output per rpm for a given process and can be calculated as follows: ST=(kg/hr)/rpm For example, if a 100-mm twin-screw extruder is successfully processing a formulation at 1000 kg/hr with 250 rpm, this equates to 4kg/rpm. ST=1000/250= 4kg/rpm Specific throughput provides a number that is proportional to the degree of fill and is used to process similar products at different rates on the same machine. For instance, if a product runs at 1000 kg/hr at 250 rpm, then for 2000 kg/hr on the same extruder 500 rpm is a good starting point. ST is often helpful to scale-up/down products on different size extruders, in that over time a process that runs 5 kg/hr on a 30-mm class machine will most likely equate to 50 kg/hr (or another rate) on a 60-mm class machine, and vice versa. 9. Rough approximation of shear Shear is what causes mixing to occur in an HSEI twin-screw extruder. Although not necessarily accurate, the following provides a rough approximation of shear: Reference intermesh shear = 10.4 x rpm x ((OD+ID)/OD) Minimum channel shear = rpm x OD/{60 x (OD-ID)}

OD=Screw outside diameter (each),

ID=Screw inside diameter (each).

For example, for a 110-mm twin-screw extruder with an OD of 110 mm and an ID of 72 mm operating at 600 rpm, the following shear calculations would apply: Reference intermesh shear = 10.4 x 600 x ((110+72)/110)= 10,324 rec/sec Minimum channel shear = 600 x 110/{60 x (110-72)} = 29 rec/sec The formula can be used as a rough estimate to match rpms for HSEI twin-screw extruders with different diameters, or to estimate the shear at a particular rpm. 10. Temperature rise during pressure generation A basic consequence of physics is that pressure generation in the extruder front-end caused by the die results in a temperature rise. The more restrictive the front-end, the higher the pressure and melt temperature rise, which may adversely effect the product. The temperature rise formula is as follows: Change in temperature (°C)=Change in pressure (bar)/2 For example: If a HSEI twin-screw extruder is processing 500 kg/hr and the die pressure is 40 bar (580 psi) then the associated melt temperature rise is approximately 20°C(Change in temperature=40/2) In addition, the extruder rpm, and the geometry of the discharge screw elements can drive the melt temperature even higher. Summary Close to 100% of polymers have been processed at some stage on an HSEI twin-screw extruder, such as in polyethylene plants at 50,000 kg/hr, to manufacture concentrates at 500 kg/hr, or to produce a catheter tube at 1 kg/hr. Regardless of the application, the basic process technologies and staging of unit operations are similar. Understanding extruder basics and applying some simple formulas and operating principles can mean the difference between success and failure for a manufacturing operation. In that vein, hopefully, the above discussion will be somewhat helpful for anyone that uses an HSEI twin-screw extruder now or in the future. Author?s note: In addition to thanking the contributors denoted (Paul Anderson, Bill Thiele, Bert Elliott), I?d also like to congratulate Dr. Todd on his recent retirement from PPI (although he?s still giving two ANTEC papers this year), as well as his 80th birthday!

Contact Information Leistritz, Somerville, NJ (908) 685-2333 [email protected]

New Kid on the Medical Molding Block Has a Plastics Pedigree

NPE Visitors Get Sneak Peak at PEK

Medical Injection Molder Schnipke Acquired by Atalys

3D Printing Fast-Tracks Plastic Tray Prototyping

Highly Wear Resistant Screws And Barrels Copyright © 2024 All rights reserved. Informa Markets, a trading division of Informa PLC.