The government has initiated an anti-dumping probe on imports of straight length bars and rods of alloy steel from China following complaints from the domestic industry. Six domestic companies, including JSW Steel, Sunflag Iron and Steel, Usha Martin and Gerdau Steel India, had submitted an application with the Directorate General of Anti-dumping and Allied Duties (DGAD) for initiation of anti-dumping investigation and imposition of the duty on these steel items exported from China.

The DGAD, under the commerce ministry, said it has prima facie found “sufficient evidence” of dumping of these products from China. “The authority hereby initiates an investigation into the alleged dumping, and consequent injury to the domestic industry,” the DGAD has said in a notification. In its probe, the directorate will determine existence, degree and effect of alleged dumping and recommend the amount of anti-dumping duty, which if levied would be adequate to remove the injury to the domestic industry. 304 Stainless Steel Round

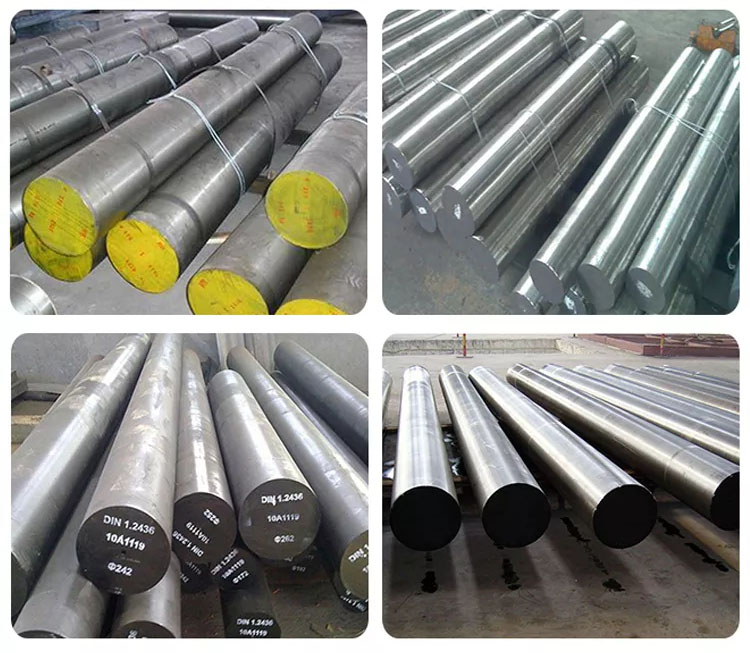

These steel products are used in several sectors, including automobiles, cement, power plants, turbines, ship-building, railways, capital goods, and construction machinery. The period of investigation for the present investigation is 2016-17. However, for the purpose of injury investigation, the period will also cover data of 2013-16, it added. While the DGAD recommends the duty, the finance ministry imposes the same.

Anti-dumping duties are levied to provide a level-playing field to the local industry by guarding against cheap below-cost imports. Increasing imports and dumping of goods from China have always been an area of concern for Indian companies.

India’s exports to China were only USD 10.17 billion in 2016-17, but imports aggregated USD 61.28 billion during that fiscal. The DGAD is also probing dumping of several other products such as certain chemicals from the neighbouring country. India is one of the most attractive markets for global producers due to its large middle class population.

8mm Round Bar Video: After Annabelle, this CREEPY DOLL is scaring strangers