Thank you for visiting nature.com. You are using a browser version with limited support for CSS. To obtain the best experience, we recommend you use a more up to date browser (or turn off compatibility mode in Internet Explorer). In the meantime, to ensure continued support, we are displaying the site without styles and JavaScript.

Scientific Reports volume 14, Article number: 3197 (2024 ) Cite this article Small Crucible For Sale

The existing black zirconia has problems such as uneven color development, poor stability, expensive raw materials, and harm to the human body and the environment. In order to solve the above problems, this paper intends to use NiAl2O4, NiTiO3, Fe2O3 as chromophore, zirconia as a matrix, and a solid-phase method is used to prepare high-performance black zirconia ceramics. The method avoids the introduction of toxic elements, and at the same time, it is more economical in the selection of color-developing pigments. The experimental results show that black zirconia ceramics with uniform color, continuous adjustment and high temperature stability can be obtained. When the sintering temperature is lower than 1450 °C and the color material mixing ratio is 10 wt.%, the mechanical properties and optical properties of the obtained samples optimum, the overall reflectance of the sample is less than 10 wt.%, which meets the conditions for market application. These black ceramics can be widely used in high-tech fields such as mobile phone backplanes, photovoltaic industry and high-end decorative materials, and have broad application prospects.

Zirconia is a recognized inorganic non-metallic material with high temperature resistance, wear resistance, good self-lubricating properties and biocompatibility1,2. There are many preparation methods for zirconia, such as solid-phase method, liquid-phase method, etc. But due to the high difficulty of operation of some liquid phase methods and serious environmental pollution, for example, waste gas pollution. In the process of preparing powder by liquid phase method, chemical reactions may produce some harmful gases, such as carbon dioxide, sulfur dioxide, nitrogen oxides, etc. If these gases are not treated or handled improperly, they may cause pollution to the atmospheric environment. In addition, there is waste liquid pollution and solid waste pollution, waste liquid will be produced in the process of preparing powder by liquid phase method, such as the remaining raw materials, catalysts, washing liquid and so on. If the waste liquid is not treated or handled improperly, it may cause pollution to the water environment. Some solid wastes produced in the process of preparing powder, such as sediments, residues, waste catalysts. If these wastes are not treated or handled improperly, they may cause pollution to the soil environment. Therefore, in order to reduce environmental pollution, the solid-phase method is generally used for the production of zirconia in factories. Colored ceramics are also widely used in medicine, photocatalytic degradation3, decoration and solar absorbers4 due to their good mechanical properties5, biocompatibility and excellent optical properties. Besides, colored zirconia is also widely used in mobile phone backplanes and luxury watch dials due to its good mechanical properties, metallic luster and signal non-shielding. As of today, people have not stopped developing new colored zirconia ceramics6, and have developed white, green, purple7, blue and other colors8. However, a large part of the preparation formula of black zirconia will be the addition of toxic metal oxides9. Such as hexavalent chromium ions, which are extremely harmful to the human body. Moreover, the high-temperature color instability and uneven color of black zirconia ceramics also hinder the application range of black zirconia10,11. S.W12 combine the advantages of additive manufacturing (AM) with those of functionally graded materials (FGM) to the development of thermoplastic 3d printing technology for ceramic-based 4D components. Black and white zirconia components are additively manufactured and co-fired without defects. Two pairs of different black and white zirconia powders were used to prepare different thermoplastic suspensions. The process parameters of single material test component were studied, and the process parameters of multi-color zirconia additive manufacturing were adjusted. Gargori et al.13 used electroplating waste Cr/Ni/Cu as a black ceramic pigment, but the color performance was not satisfactory, in which the L* value was < 40 and the a* and b* value showed a nonlinear distribution, which indicated the color effect is not bright black. Costa14 used the solid-state method and found that the sample obtained by forming spinel with Fe, Ni, and Cr as the main phase has the best color rendering effect, and these raw materials can usually be obtained by recycling industrial waste. The color performance of the sample is better. Jiang Feng et al.15 successfully developed a novel colorant using solid-state method, with Fe2O3 and manganese oxide as the coloring groups. Its L* value is 23.19, but a* and b* values are large. However, as a cobalt-free colorant, this is undoubtedly innovative. Mengke Liu16 prepared cobalt-free black ceramic pigments from stainless steel steelmaking dust, and studied its coloring mechanism. When Fe:Cr:Mn:Ni = 1:1:1:1, it was sintered at 1125 °C. After 30 min, a sample with uniform and excellent performance was obtained, and the coloring performance of the color material was better than that of the cobalt-containing color material sold on the market. Li Zhiqiao17 prepared black ceramics using Fe2O3,Cr2O3, MnO and NiO as raw materials by solid phase method , the main phases of which are NiFe2O4,NiCr 2 O 4 and Ni [Mn0.5Cr1.5] O4, the color is pure black, and with the increase of the amount of pigment added, the black becomes brighter and has excellent coloring performance, the L*, a* and b* values of the prepared sample are 18.02, 0.20 and 0 respectively. D. Melo18 and others tried to replace part of Co in lanthanum cobaltate with Ca to reduce the cost. N. W. Solís et al.19 prepared 3Y-TZP/GO composites by using zirconium-GO mixture by spark plasma sintering. The simultaneous sintering and in-situ reduction of graphene oxide opens up a very interesting technical route for the preparation of such materials. The effect of graphene content on the electrical, mechanical and optical properties of the material was studied, and the nanostructured black zirconia was obtained. The above-mentioned preparation methods of black zirconia ceramics all have problems such as not being close enough to black or introducing toxic metal oxides and high cost. Therefore, it is urgent to develop an environmentally friendly and economical black pigment doped with non-toxic metal oxides.

In this study, nickel oxide was used instead of cobalt oxide to prepare blue NiAl2O4. The green color material synthesized by NiAl2O4 and NiTiO3 is mixed with iron oxide red to obtain black color material, which greatly improves the use value of black zirconia. And the application of the solid phase method has no requirements on the sintering atmosphere and pressure, and the preparation is simple20,21. Based on the above research results, continuously tunable black zirconia ceramics with good mechanical and optical properties, economical and environmental protection can be prepared. The black ceramics can be widely used in high-tech fields such as mobile phone backplanes, photovoltaic industry22 and high-end decorative materials, and have broad application prospects.

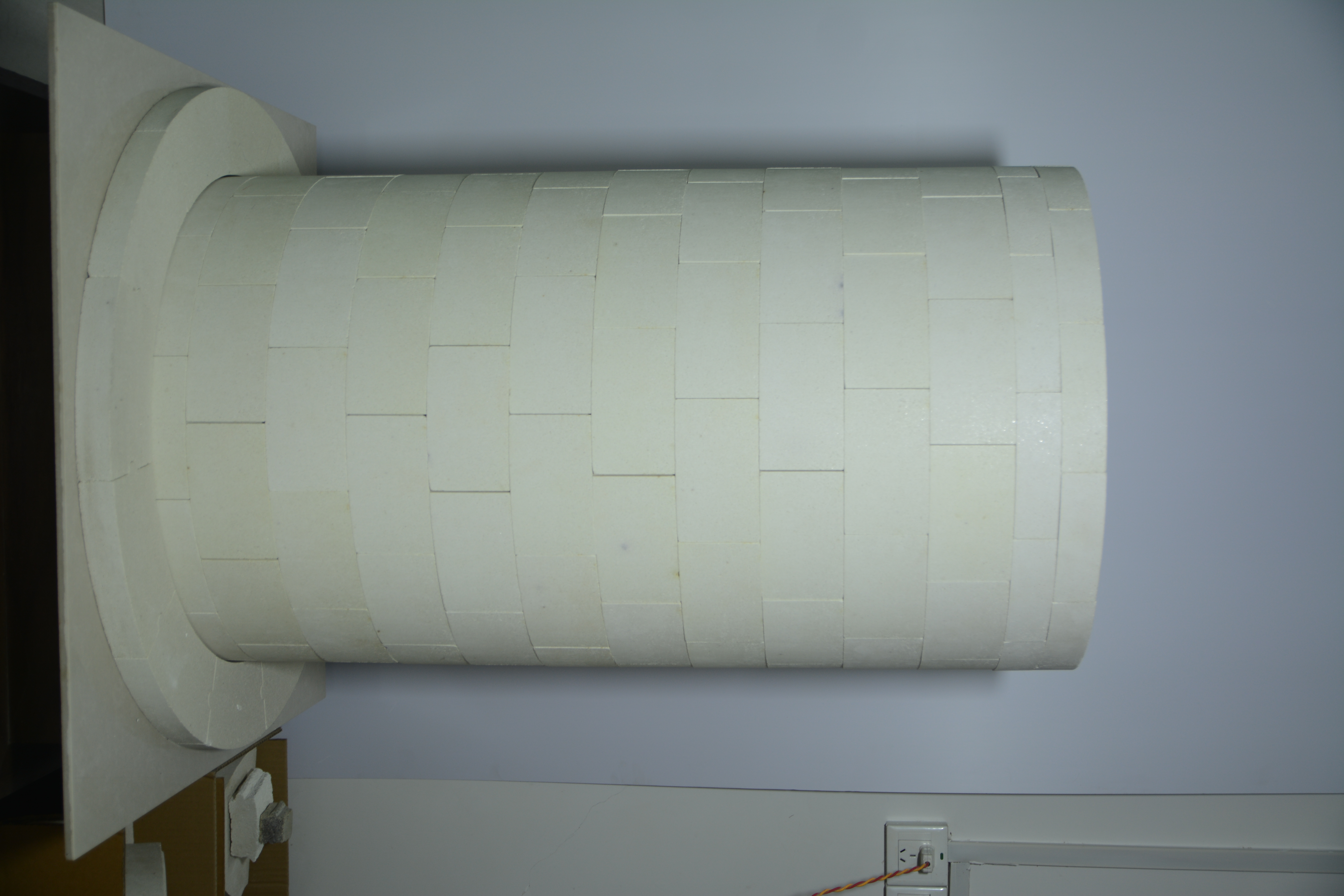

In this paper, black zirconia ceramics were prepared by solid-phase method, with nano-scale zirconia stabilized by Y2 O3 as the matrix, and black zirconia ceramics were prepared according to the superposition principle of three primary colors of pigments. All raw materials used are shown in Table 1. First, prepare the NiAl2O4 precursor and the NiTiO3 precursor, mix TiO2, Al2O3 and NiO in proportion and perform ball milling for 24 h to obtain NiAl2O4 and NiTiO3, and then put them in a drying oven to dry. Afterwards, the prepared precursor and Fe2O3 were added to zirconia as a colorant, and after ball milling for 24 h, they were placed in a drying oven to dry, and the obtained agglomerated powder was ground and passed through a sieve to obtain a smaller particle size. Powder, by changing the doping amount of NiAl2O4, NiTiO3 and Fe2O3, ranging from 1 wt.%, 4 wt.%, 7 wt.%, 10 wt.%, and sintering temperature, to explore the influence on the performance of zirconia ceramics. Table 2 shows the mass percentage of raw materials. Figure 1 is preparation flowchart:

Weigh the raw materials according to the stoichiometric ratio and put them into the ball mill tank. The role of ball milling is to crush the raw material so that it meets the required granularity requirements. The purpose of adding anhydrous ethanol as a dispersant is to promote the dispersion and uniformity of the powder.

Ball mill with a planetary ball mill for 24 h, and then put the resulting slurry into a constant temperature drying oven at 80 °C to dry. The goal is to remove the alcohol and get the powder.

Grind the resulting powder with an agate mortar and sift it. The grinding process can change the shape and surface topography of the sample and increase the specific surface area of the material, thereby increasing the chance of interaction and reaction to obtain fine sample particles.

Press the obtained powder on the electric tablet press, and then press the obtained prepressed body at 200 MPa cold isostatic pressure. The aim is to reduce the distance between molecules without changing the appearance of the shape, thereby improving the physical properties of the substance.

The obtained embryo body is sintered at 1350 ℃, 1400 ℃, 1450 ℃, 1500 ℃, 1550 ℃ for 3 h, the purpose is to make the grain grow, the void is reduced, and the sample has better mechanical properties.

Preparation process of black zirconia.

Details of all instruments are shown in Table 3. In this experiment, XRD was used to detect the phase of black zirconia, and the instrument produced by PANalytical company in the Netherlands was used. The scanning speed was 2°/min and the scanning range was 20°–70°. The phase information in the sample can be obtained by XRD, and then the material for further study, a metal copper block, is used as a diffraction target with a rated operating voltage of 40 kV and a rated current of 35 mA.

The fracture and surface morphology of ceramic samples were observed by SIMGA-300 scanning electron microscopy. The samples were first treated with gold spraying for about 200 s to improve their electrical conductivity, and then placed in the sample chamber and vacuumed. Colorimetric measurement was carried out by CIE 1976 L* a* b* colorimetric method.

In order to characterize the color change of the sample, the measurement was performed using a CM-3600A colorimeter. In a darkened room, the instrument is calibrated and the polished surface of the sample is wiped clean with an alcohol sponge. The samples were then tested with a UV-3900 UV–visible spectrophotometer. First, the pure white alumina dry pressed block is taken as the standard sample. After the instrument is calibrated, the complete ceramic sample sheet is polished to the surface without scratches by an automatic polishing machine, and the sample is scanned at a scanning rate of 2 nm/s to collect the reflectance between 200 and 800 nm, and the reflectance and reflection spectral range of the sample are measured.

Hardness characterization Vickers hardness is used to measure the relevant properties of a material. The HV-50 Vickers hardness tester is used to test polished ceramic sheets. The hardness test pressure is 5kgf and the holding time is 15 s. Hardness and toughness can be calculated by the calculation tool embedded in the test software, thus avoiding the error factor caused by manual calculation. The calculation methods of Vickers hardness and fracture toughness are as forum (1), (2):

The crystal structure and phase of 3YSZ doped with NiAl2O4, NiTiO3, Fe2O3 as colorants were studied by XRD. The obtained XRD is shown in Fig. 2a (x is Fe2O3, NiAl2O4, NiTiO3 total mass fraction), it can be seen from the figure that different doping amounts have similar diffraction peaks, and when the colorant doping ratio is lower than 1wt.%, no peak of the FeAl2O4 is found in the XRD spectrum. The diffraction peaks indicate that the color material is basically solid-dissolved into zirconia at this time. As the color material mixing ratio increases to 7wt.% and above, it can be seen that there are monoclinic zirconia peaks and diffraction peaks of iron-aluminum spinel around 28° and 32°.This indicates that the amount of colorant that can be solid-dissolved in the zirconia matrix reaches a saturated value at this time. In the case of not changing the color material ratio, the sintered batch samples were sintered at 1350 °C, 1400 °C, 1450 °C, 1500 °C, and 1550 °C with a color material content ratio of 7 wt.%. From the obtained XRD Fig. 2b, it can be seen that with the increase of sintering temperature, the peak intensity of the diffraction peak of monoclinic zirconia in the sample gradually becomes stronger, which is due to the fact that when the sintering temperature is too high, the phenomenon of overburning occurs, and the appearance of the monoclinic phase may generally have a negative impact on the mechanical properties of the sample.

XRD pattern (a) of different colorant blending ratios, XRD pattern (b) of different sintering temperatures.

In order to further investigate the influence of color doping amount on the crystal vibration mode of the sample, Raman spectroscopy was used to analyze the sample. As can be seen from the Raman spectrum in Fig. 3a, when the color doping content is 1%, the sample is mainly tetragonal zirconia, which is marked by short lines in the figure. With the increase of doping amount of color material, in addition to tetragonal zirconia, monoclinic zirconia peaks also appeared in 179 cm–1, 337 cm–1, 472 cm–1 and 634 cm–1, which were marked by dot lines in the figure. At the position of 253 cm–1, the diffraction peak of the tetragonal phase begins to decrease, and the diffraction peak of the monoclinic phase increases, indicating that excessive doping amount of color material will affect the phase structure of the sample. As can be seen from Fig. 3b, when the sintering temperature rises to more than 1400 ℃, a monoclinic zirconia peak also appears at the position of 179 cm–1, and the intensity of diffraction peak is higher than that of tetragonal zirconia peak. This shows that the proportion of monoclinic phase in zirconia increases with the increase of sintering temperature.

Raman pattern (a) of different colorant blending ratios, Raman pattern (b) of different sintering temperatures.

SEM diagrams of ceramic samples at different sintering temperatures respectively, and a, b, c, and d in Fig. 4 are the microscopic appearance of samples with different doping amounts of colorants. It can be seen that the grain growth is relatively good, the size is uniform. By measuring the density of the sample using the drainage method, we found that the density of the sample is high, the density test results are shown in Table 4. And the grain shape in the figure is rounded for the zirconia grain. In the case of doping ratio, it has little effect on the grain size of the main phase. Figure 5a and b are the microscopic appearance of the sample surface at different sintering temperatures. Combining with the morphology under the electron microscope, it can be seen that as the sintering temperature increases, the crystal grains also become larger. As shown in Table 4, the grain size also increases with increasing temperature. When the temperature is 1450 ℃ and above, the grains grow abnormally, and the abnormally grown grains will affect the mechanical properties of the sample. First, the abnormally grown grains will reduce the volume of the surrounding grain boundaries, making the original thermal mismatch stress of zirconia grains and iron-aluminum spinel grains with different thermal expansion coefficients increases, which increases the internal stress of the sample, while the grains grow abnormally, exceeding the phase transition size, and a large number of tetragonal phases transform into monoclinic phase, the number of holes increases, which also leads to poor mechanical properties of the sample. This is consistent with the mechanical properties results obtained below.

SEM images of cross-sections under different coloring ratios (x = 1, 4, 7, 10 wt.%).

Surface SEM images at different sintering temperatures T = 1400 °C (a), T = 1450 °C (b).

As the data shown in Table 5, the brightness values of all the samples are greater than 40. And the a* and b* values of the samples are close to 0, except for the sample with 1 wt.% colorant doping. It can be concluded from the above data that the samples are bright black. As can be seen from Table 6, when the sintering temperature increases, the brightness value of the sample becomes higher, which is caused by a small amount of volatilization of the colorant at high temperatures. At this time the a* and b* values are still extremely close to 0, indicating that the sample at this time for the pure black color. Figure 6a and b are the UV reflectivity of samples with different amounts of pigment doping and different sintering temperatures, respectively. As can be seen from the Fig. 6a, except for the colorant doping of 1wt.%, the rest of the samples have no obvious reflection peaks. From the Fig. 6b, the reflectance of the sample did not produce a substantial change with the change in sintering temperature. Figure 7 shows the actual picture of the sample when the color doping content is 7 wt.% and the sintering temperature is 1350 ℃

UV reflection diagram of different pigment blending ratios (a), UV reflection diagram of different sintering temperatures (b).

Through the Vickers hardness and toughness calculation formula, the values of different pigment doping and different sintering temperatures can be obtained. From the overall trend of Fig. 8a and b, it can be seen that with the increase of pigment doping, the Vickers hardness and fracture toughness of the sample show a downward trend. The density of samples doped with different color materials was tested, and the results were shown in Table 7. The overall density of the sample showed a decreasing trend, which was consistent with the obtained test results of mechanical properties. It can be seen from Fig. 8a that the Vickers hardness and fracture toughness of the sample decrease with the addition of pigments. As dopants, the pigments reduce the original pure zirconia the mass fraction, and with the increase of the amount of pigment added, the pigment may also react with the stabilizer in zirconia, causing the sample to be unable to stabilize in the tetragonal phase, so it is mixed in ceramics based on zirconia too much will reduce the mechanical properties of zirconia ceramics, thus the mechanical properties of the samples show a downward trend. The lowest Vickers hardness is 11.73GPa, which can meet the requirements of commercial application. It can be seen from Fig. 8b that the Vickers hardness and fracture toughness also decrease with the increase of the sintering temperature. It can be seen from the combined XRD diffraction pattern that when the temperature rises, the content of zirconia in the monoclinic phase increases sharply. The change of phase structure of zirconia is often accompanied by the change of volume, which will increase the number of cavities inside the sample, resulting in the deterioration of the mechanical properties of zirconia, and the occurrence of overburning, which will cause a large change in the grain size. The internal stress becomes larger, so the mechanical properties become worse.

Vickers hardness and fracture toughness diagram of different pigment mixing ratios (a), Vickers hardness and fracture toughness diagram of different sintering temperatures (b).

This paper reports a new method of preparing black zirconia ceramics without cobalt and non-toxic pigment doping. This sample exhibits enhanced visible light absorption and phase stability. The lightness L* of the sample is about 43.62, and the a* and b* values are close to 0, all of which indicate that the sample is bright black. In addition, the color distribution of black ceramics is uniform and the color is stable. When the sintering temperature is 1400 ℃, the mechanical properties are the best, the highest can reach 12.6 GPa, and the reflectance of the samples are lower than 10 wt.%, so the samples prepared in this experiment meet the market requirements and have good application prospects.

All data generated or analysed during this study are included in this published article.

Lv, H. et al. Optical and mechanical properties of purple zirconia ceramics. J. Asian Ceram. Soc. 7(3), 306–311 (2019).

Fanling, Q. et al. Preparation of black zirconia ceramics by non-uniform precipitation method. J. Chin. Ceram. Soc. 39(8), 1290–1294 (2011).

Teeparthi, S. R., Awin, E. W. & Kumar, R. Dominating role of crystal structure over defect chemistry in black and white zirconia on visible light photocatalytic activity. Sci. Rep. 8(1), 5541 (2018).

Article ADS PubMed PubMed Central Google Scholar

Elisa Sani, D. S., Capiani, C. & Silvestroni, L. Colored zirconia with high absorbance and solar selectivity. Scr. Mater. 186, 147–151 (2020).

Fokin, P. V. et al. Effect of drying methods of alumina powder and graphene oxide mixture on the mechanical and electrical properties of sintered composites fabricated by spark plasma sintering. Inorg. Mater. Appl. Res. 9, 930–936 (2018).

Liu, H. F. et al. Current status and prospects of research on black ceramic colorants. China Ceram. Ind. 20(06), 32–34 (2013).

Nataliia Gorodylova, VK, Dohnalová, Ž, Bělina, P. & Šulcová, P. New purple-blue ceramic pigments based on CoZr4(PO4)6.Dyes Pigments 98(3), 393–404 (2013).

Moya, J. S., Requena, R. M. J. & Soria, J. Black color in partially stabilized zirconia. J. Am. Ceram. Soc. 71(11), 479–480 (1988).

Chang, Q. et al. Encapsulated carbon black prepared by sol–gel-spraying: A new black ceramic pigment. J. Eur. Ceram. Soc. 34(13), 3151–3157 (2014).

Liu, S. et al. Current situation and future prospects of research on black ceramic pigments. Chin. Ceram. Ind. Mag. 20(6), 32–34 (2013).

Xiang, Z. et al. Research progress of cobalt-free spinel black ceramic pigments. Bull. Chin. Ceram. Soc. 40(04), 1318–1329 (2021).

Steven Weingarten, U. S. et al. Multi-material ceramic-based components – additive manufacturing of blackand-white zirconia components by thermoplastic 3D-printing (CerAM - T3DP). J. Vis. Exp. https://doi.org/10.3791/57538-v (2019).

Gargori, C. et al. Recycling of Cr/Ni/Cu plating wastes as black ceramic pigments. Mater. Lett. 218, 341–345 (2018).

Costa, G. et al. Synthesis of black ceramic pigments from secondary raw materials. Dyes Pigments 77(1), 137–144 (2008).

Jiang, F. et al. Preparation and coloring properties of new aluminum titanate-based cobalt-free black colorants. Chin. Ceram. 58(11), 68–74 (2022).

Mengke, L. et al. Preparation and coloring mechanism of cobalt-free black ceramic pigments from stainless steelmaking dust. Mater. Today Commun. 33, 10649 (2022).

Li, Z. et al. Preparation of Fe-Cr-Ni-Mn black ceramic pigment from stainless steelmaking dust. J. Chin. Ceram. Soc. 50(6), 1557–1565 (2022).

Melo, D. et al. Lanthanum cobaltite black pigments with perovskite structure. Dyes Pigments 98(3), 459–463 (2013).

Solís, N. W. et al. Electrically conductor black zirconia ceramic by SPS using graphene oxide. J. Electroceram. 38, 119–124 (2017).

Lv, H. et al. Development mechanism of Ce-doped red zirconia ceramics prepared by a high-temperature reduction method. J. Alloys Compd. 797, 931–939 (2019).

Lv, H. et al. Preparation and properties of black Ti-doped zirconia ceramics. J. Mater. Res. Technol. 9(3), 6201–6208 (2020).

Elisa Sani, A. L. M. A., Jean-Louis Sans, B. & Sciti, D. Optical properties of black and white ZrO2 for solar receiver applications. Solar Energy Mater. Solar Cells 140, 477–482 (2015).

School of Materials and Metallurgy, Inner Mongolia University of Science and Technology, Baotou, 014010, Inner Mongolia, China

Yuxuan Ding & Qingchun Wang

Inner Mongolia Autonomous Region Key Laboratory of Advanced Ceramic Materials and Devices, Baotou, 014010, Inner Mongolia, China

Yuxuan Ding & Qingchun Wang

You can also search for this author in PubMed Google Scholar

You can also search for this author in PubMed Google Scholar

Y.D. wrote the manuscript, and Q.W. reviewed the manuscript and made many important comments.

The authors declare no competing interests.

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

Ding, Y., Wang, Q. Preparation and research of new black zirconia ceramics. Sci Rep 14, 3197 (2024). https://doi.org/10.1038/s41598-024-53793-8

DOI: https://doi.org/10.1038/s41598-024-53793-8

Anyone you share the following link with will be able to read this content:

Sorry, a shareable link is not currently available for this article.

Provided by the Springer Nature SharedIt content-sharing initiative

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.

Scientific Reports (Sci Rep) ISSN 2045-2322 (online)

Wear Resistant Paint Sign up for the Nature Briefing newsletter — what matters in science, free to your inbox daily.