Affiliate links on Android Authority may earn us a commission. Learn more.

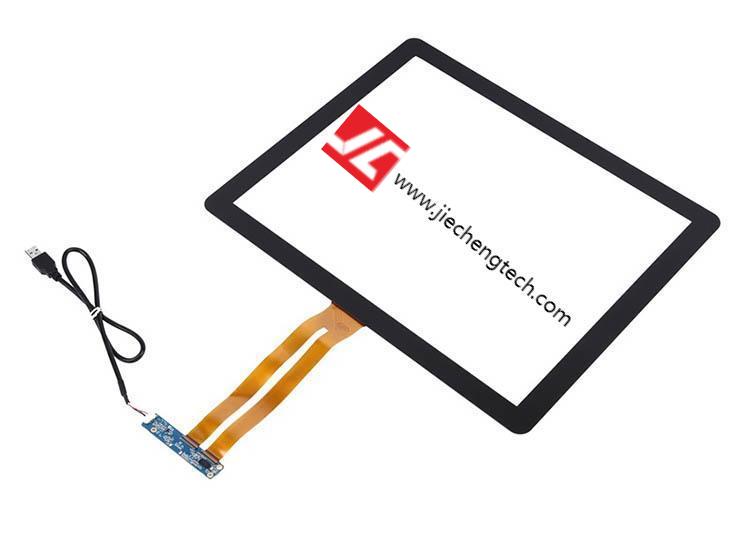

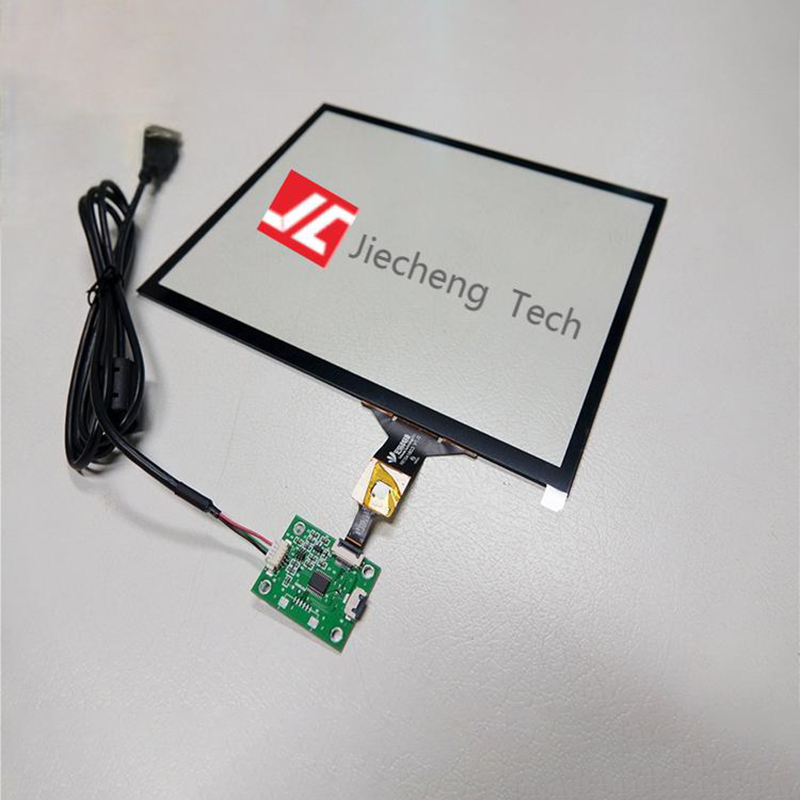

The display industry has come a long way in recent years. With so many competing standards on the market today, it’s often hard to tell if an emerging technology is worth paying extra for. OLED and QLED, for instance, sound similar enough on the surface but are, in fact, completely different display types. Lcd Touch Screen Panel

All of this is great from a technological standpoint — progress and competition generally equal better value for the end-user. In the short term, however, it has certainly made shopping for a new display somewhat complicated.

To help with that decision, we’ve summarized all mainstream display types in this article, along with the pros and cons of each. Consider bookmarking this page and returning to it the next time you’re in the market for a new television, monitor, or smartphone.

LCDs, or liquid crystal displays, are the oldest of all display types on this list. They are made up of two primary components: a backlight and a liquid crystal layer.

Put simply, liquid crystals are tiny rod-shaped molecules that change their orientation in the presence of an electric current. In a display, we manipulate this property to allow or block light from passing through. This process is also aided by color filters to produce different subpixels. These are essentially shades of red, green, and blue primary colors that combine to form the desired color, as shown in the above image. At a reasonable viewing distance, individual pixels are (usually) invisible to our eyes.

Since liquid crystals don’t produce any light by themselves, LCDs rely on a white (or sometimes blue) backlight. The liquid crystal layer then simply has to let this light pass through, depending on the image that needs to be displayed.

A lot about a display’s perceived image quality hinges on the backlight, including aspects such as brightness and color uniformity.

You may have noticed that the term LCD has started to disappear of late, especially in the television industry. Instead, many manufacturers now prefer branding their televisions as LED models instead of LCD. Don’t be fooled, though — this is just a marketing ploy.

These so-called LED displays still use a liquid crystal layer. The only difference is that the backlights used to illuminate the display now use LEDs instead of cathode fluorescent lamps, or CFLs. LEDs are a better light source than CFLs in almost every way. They are smaller, consume lesser power, and last longer. However, the displays are still fundamentally LCDs.

With that out of the way, let’s take a look at the different types of LCDs on the market today and how they differ from each other.

Twisted nematic, or TN, was the very first LCD technology. Developed in the late 20th century, it paved the way for the display industry to transition away from CRT.

TN displays have liquid crystals laid out in a twisted, helical structure. Their default “off” state allows light to pass through two polarizing filters. However, when a voltage is applied, they untwist themselves to block light from passing through.

TN panels have been around for decades in devices like handheld calculators and digital watches. In these applications, you only need to power sections of the display where you don’t want light. In other words, it is an incredibly energy-efficient technology. Twisted nematic panels are also cheap to manufacture.

The same system can also give you a color image if you use a combination of red, blue, and green subpixels.

However, TN displays have some major downsides, including narrow viewing angles and poor color accuracy. This is because most of them use sub-pixels that can only output 6 bits of brightness. That limits the color output to just 26 (or 64) shades of red, green, and blue. That’s a lot less than 8 and 10-bit displays, which can reproduce 256 and 1,024 shades of each primary color respectively.

In the early 2010s, many smartphone manufacturers used TN panels as a way to keep costs down. However, the industry has almost entirely moved away from it. The same holds true for televisions, where wide viewing angles are a critical selling point, if not a necessity.

Having said that, TN is still in use elsewhere. You are most likely to find it on low-end personal use devices like budget Chromebooks. And despite its faults, TN is also extremely popular among competitive gamers because it boasts low response times.

IPS, or in-plane switching technology, offers a noticeable step-up in image quality compared to TN displays.

Instead of a twisted orientation, liquid crystals in an IPS display are oriented parallel to the panel. In this default state, light is blocked — the exact opposite of what happens in a TN display. Then, when a voltage is applied, the crystals simply rotate in the same plane and let light through. As a side note, this is why the technology is called in-plane switching.

IPS displays were originally developed to deliver wider viewing angles than TN. However, they also offer a myriad of other benefits, including higher color accuracy and bit-depth. While most TN panels are limited to the sRGB color space, IPS can support more expansive gamuts. These parameters are important for playing back HDR content and are downright necessary for creative professionals.

Having said that, IPS displays do come with a few minor compromises. The technology isn’t nearly as energy-efficient as TN, nor is it as cheap to manufacture at scale. Still, if you care about color accuracy and viewing angles, IPS is likely your only option.

In a VA panel, liquid crystals are oriented vertically instead of horizontally. In other words, they are perpendicular to the panel, and not parallel like in IPS.

This default vertical arrangement blocks a lot more of the backlight from coming through to the front of the display. Consequently, VA panels are known for producing deeper blacks and offering better contrast compared to other LCD display types. As for bit-depth and color gamut coverage, VA is capable of doing just as well as IPS.

On the downside, the technology is still relatively immature. Early VA implementations suffered from extremely slow response times. This led to ghosting, or shadows behind fast-moving objects. The reason for this is simple — it takes longer for VA’s perpendicular arrangement of crystals to change orientation.

Having said that, some companies like LG are experimenting with technologies like pixel overdrive to improve response times.

However, VA displays also have narrower viewing angles than IPS panels. Still, most VAs come out on top when compared to even the best TN implementations.

OLED stands for Organic Light Emitting Diode. The organic part here simply refers to carbon-based chemical compounds. These compounds are electroluminescent, which means that they emit light in response to an electric current.

From this description alone, it’s easy to see how OLED differs from LCD and prior display types. Since the compounds used in OLEDs emit their own light, they are an emissive technology. In other words, you don’t need a backlight for OLEDs. This is why OLEDs are universally thinner and lighter than LCD panels.

Since each organic molecule in an OLED panel is emissive, you can control whether a particular pixel is lit up or not. Take away the current and the pixel turns off. This simple principle allows OLEDs to achieve remarkable black levels, outperforming LCDs that are forced to use an always-on backlight. Besides delivering a high contrast ratio, turning off pixels also reduces power consumption.

The contrast alone would make the technology worth it, but other benefits exist too. OLEDs boast high color accuracy and are extremely versatile. Foldable smartphones such as the Samsung Galaxy Flip series simply wouldn’t exist without AMOLED’s physical flexibility.

OLED’s Achilles heel is that it is prone to permanent image retention or screen burn-in. This is the phenomenon where a static image on the screen can become embossed, burned-in, or simply age differently over time. Having said that, manufacturers now employ several mitigation strategies to prevent burn-in.

Both AMOLED and POLED are common terms in the smartphone industry but don’t convey any particularly useful information.

The AM bit in AMOLED refers to the use of an active matrix circuit for supplying current, as opposed to the more primitive passive matrix (PM) approach. The P in POLED, meanwhile, indicates the use of a plastic substrate at the base. Plastic is thinner, lighter, and more flexible than glass. There’s also Super AMOLED, which is just fancy branding for a display that has an integrated touch screen digitizer.

Even though Samsung uses the Super AMOLED branding, many of its displays use a plastic substrate too. Smartphones with curved screens would not be possible without the flexibility of plastic. Similarly, almost every POLED display uses an active matrix. The distinction between AMOLED vs POLED has diminished greatly in recent times.

In summary, OLED subtypes aren’t nearly as varied as LCDs. Furthermore, only a handful of companies manufacture OLEDs so there’s even less quality variance than you’d expect. Samsung manufactures the majority of OLEDs in the smartphone industry. Meanwhile, LG Display has a near-monopoly on the large-sized OLED market. It supplies panels to Sony, Vizio, and other giants in the television industry.

In the section on LCDs, we saw how the technology can vary based on differences in the liquid crystal layer. Mini-LED, however, attempts to improve contrast and image quality at the backlight level instead.

The backlights in conventional LCDs have only two modes of operation — on and off. This means that the display has to rely on the liquid crystal layer to adequately block light in darker scenes. Failing to do that results in the display producing grays instead of true black.

Some displays, however, have adopted a better approach recently: they divide the backlight into zones of LEDs. These can then be individually controlled — either dimmed or turned off completely. Consequently, these displays deliver much deeper black levels and higher contrast. The difference is immediately apparent in darker scenes.

This technique, known as full array local dimming, has become ubiquitous in higher-end LCD televisions. Until recently, though, it wasn’t viable for smaller displays like those found in laptops or smartphones. And even in larger devices like monitors and TVs, you run the risk of not having enough dimming zones.

Enter mini-LED. Like the title suggests, these are significantly smaller than the LEDs you’d find in conventional backlights. More specifically, each mini-LED measures just 0.008 inches or 200 microns across.

Mini-LEDs allow display manufacturers to increase the number of local dimming zones from a few hundred to several thousand. As you’d expect, more zones equals granular control over the backlight. Their smaller footprint also makes them perfect for smaller devices like smartphones, tablets, and laptops. Finally, the abundance of LEDs also helps to boost the overall brightness of the display.

Tiny, bright objects against a black background look much better on a mini-LED display as compared to one with conventional LED backlighting. However, the contrast ratio still isn’t in the same ballpark as OLED.

Despite the increased density, most mini-LED displays today simply don’t have enough dimming zones to match OLEDs in terms of contrast.

Take the 2021 iPad Pro, for example. It was among the first consumer devices to adopt mini-LED technology. Even with 2,500 zones across 12.9 inches, however, some users reported blooming or halos around bright objects.

Still, it’s not hard to see how mini-LEDs can eventually deliver better contrast than conventional local dimming implementations. Furthermore, since mini-LED displays still rely on traditional LCD technologies, they aren’t prone to burn-in like OLEDs.

Quantum dot technology has become increasingly common — usually positioned as a key selling point for many mid-range televisions. You may also know it by Samsung’s marketing shorthand: QLED. Similar to mini-LED, however, it isn’t some radically new panel technology. Instead, quantum dot displays are basically conventional LCDs with an additional layer sandwiched in between.

Traditional LCDs pass white light through multiple filters to get a specific color. This approach works well, but only to a certain point.

Many older display types are capable of fully covering the decades-old standard RGB (sRGB) color gamut. However, the same cannot be said for wider gamuts like DCI-P3. Coverage of the latter is important because that’s the color gamut predominantly used in HDR content.

So how do quantum dots help? Well, they are essentially tiny crystals that emit color when you shine blue or ultraviolet light on them. This is why quantum dot displays use a blue backlight instead of white.

A quantum dot display contains billions of these nanocrystals spread across a thin film. Then, when the backlight is turned on, these crystals are capable of producing extremely specific shades of green and red. The exact shade depends on the size of the crystal itself.

When combined with traditional LCD color filters, quantum dot displays can cover a greater percentage of the visible light spectrum. Put simply, you get richer and ore accurate colors — enough to deliver a satisfactory HDR experience. And since the crystals emit their own light, you also get a tangible bump in brightness compared to traditional LCDs.

However, quantum dot technology does not improve other pain points of LCDs such as contrast and viewing angles. For that, you’d have to combine quantum dots with local dimming or mini-LED technologies. Samsung’s high-end Neo QLED TVs, for example, combine QLED with Mini-LED tech to match OLED’s deep blacks.

Quantum-dot OLED, or QD-OLED, is an amalgamation of two existing technologies — quantum dots and OLED. More specifically, it aims to eliminate the drawbacks of both traditional OLEDs and LCD-based quantum dot displays.

In a traditional OLED panel, each pixel is composed of four white sub-pixels. The idea is rather simple: since white contains the entire color spectrum, you can use red, green, and blue color filters to obtain an image. However, this process is rather inefficient. As you’d expect, blocking large portions of the original light source leads to significant brightness loss by the time the image reaches your eyes.

Modern OLED implementations combat this by leaving the fourth sub-pixel white (without any color filters) to improve the perception of brightness. However, they still usually fall short in terms of brightness, especially against high-end LCDs with larger backlights.

QD-OLED, on the other hand, uses a completely different subpixel arrangement — these displays start with blue emitters instead of white. And instead of color filters, they use quantum dots. In the previous section on QLED, we discussed how quantum dots are capable of producing extremely specific shades of green and red. The same property comes into play here as well. Put simply, quantum dots convert the original blue light into various colors instead of destructively filtering it, preserving the display’s overall brightness.

According to Samsung Display, another advantage QD-OLED brings to the table comes in the form of better color accuracy. Since these displays don’t have a fourth white sub-pixel, color information is rendered correctly even at higher brightness levels. Finally, quantum dots allow displays to achieve higher color gamut coverage and offer wider viewing angles than color filters.

However, it’s still early days for the technology as a whole. Traditional OLEDs have enjoyed a nearly decade-long head start yet remain relatively unaffordable. It remains to be seen if QD-OLED televisions and monitors can compete in terms of price and durability, especially considering the risks of image retention or burn-in with organic compounds.

MicroLED is the newest display type on this list and, as you’d expect, also the most exciting. Put simply, microLED displays use LEDs that are even smaller than those used in mini-LED backlights. While most mini-LEDs are around 200 microns in size, microLEDs are as small as 50 microns. For context, human hair is thicker than that at 75 microns.

Their small size means that you can build an entire display out of microLEDs alone. The result is an emissive display — much like OLED, but without the drawbacks of that technology’s organic component. There’s no backlight either, so each pixel can be turned off completely to represent black. All in all, the technology delivers an exceptionally high contrast ratio and wide viewing angles.

Brightness is another aspect in which microLED displays manage to surpass existing technologies. Even the highest-end OLED displays on the market today, for instance, top out at 2,000 nits. On the other hand, manufacturers claim that microLED can eventually deliver a peak brightness output of 10,000 nits.

Finally, MicroLED displays can also be modular. Even some of the earliest demonstrations of the technology had manufacturers creating giant video walls using a grid of smaller microLED panels.

Samsung offers its flagship The Wall microLED display (pictured above) in configurations ranging from 72 inches all the way to 300 inches and beyond. With a million-dollar price tag, though, it is clearly not a consumer product. Still, it offers a glimpse into the future of televisions and display technology in general.

It’s almost certain that microLED displays will become more accessible and cheaper in the coming years. After all, OLED is only a decade old at this point and has already become ubiquitous.

15 Inch Touch Screen Display And with that, you’re now up to speed on every display technology on the market today! Display types can vary significantly and the best type will depend on the characteristics you deem important or require the most. Having said that, you can’t go wrong with any of the cutting-edge technologies on the market today, namely OLED and Mini-LED.