It was a long time coming, but all those promises about CVD diamond-coated carbide tools are finally being fulfilled. And just about every carbide toolmaker in the United States is after a piece of the action.

At the 1994 International Manufacturing Technology Show in Chicago last September, four tool companies—Crystallume, Menlo Park, CA; Sandvik Coromant Co., Fair Lawn, NJ; Kennametal Inc., Latrobe, PA; and Teledyne Advanced Materials-Cutting Tools, La Vergne, TN—displayed CVD diamond-coated carbide inserts. Statements from other big firms such as Valenite Inc., Madison Heights, MI; Mitsubishi Materials Corp., Garden Grove, CA; and Carboloy Inc., Detroit indicated that they too would soon be offering CVD diamond carbide tools. Drill Inserts

The good news for end users is that they now have the happy problem of deciding when to use PCD tools and when to use CVD diamond-coated carbide tools. Let’s examine how CVD diamond coating works and why it is such an important advancement in coating technology.

Making diamond films at low pressures is a remarkably simple process. CVD diamond is made when a mixture of between 1 and 5 atomic percent methane in hydrogen is chemically excited to produce hydrogen and hydrocarbon radicals. In most commercial systems, excitation is performed using microwave radiation. A diamond film is formed on a surface held to about 900°C in proximity to the excited gas. Typical pressures are subatmospheric (20 to 100 Torr) and deposition rates for tool applications range between 0.1µm/hr. and 10.0µm/hr., depending on the design and power of the reactor.

This synthetic diamond for cutting tool applications is an agglomeration of small (typically 1µm- to 10µm-dia.) crystals (Figure 1). Each crystal is virtually identical to natural diamond and high-pressure synthetic diamond, only purer in most cases. Each crystal is bound strongly to its neighbors as evidenced by transgranular fracture surfaces.

Applied Science and Technology Inc. (ASTeX), Woburn, MA, has developed several commercially available turnkey microwave reactors capable of fully automated diamond deposition over areas up to 12" in diameter (Figure 2). The throughput of the largest ASTeX reactor is 300 SPG-422-style tools coated with 20µm-thick CVD diamond per day. A smaller version capable of coating 50 tools per day also is available.

Because of recent technological advancements such as the ASTeX reactor, smaller toolmakers can now participate in the CVD diamond market. One form of participation is known as toll coating. Here, a company offers to diamond-coat another manufacturer’s tool. For example, Teledyne’s CVD diamond products are actually coated by a small firm named sp3, Mountain View, CA. Other forms of participation for smaller tool houses include coating custom tools and manufacturing thick-film CVD diamond for PCD replacement. As a result of smaller companies getting involved, users will get to choose their CVD diamond tools from a greater number of tool manufacturers than they might have expected.

Diamond tools have long filled an industry need for machining nonferrous abrasive materials such as high-silicon aluminum. Such materials cannot be machined economically using carbide tools. For many years, tool manufacturers have produced diamond tools consisting of artificial diamond grit manufactured at high pressure and temperature and then compacted, with cobalt as a binder, to produce a solid known as PCD. The PCD is then cut and brazed onto a corner of a cutting tool.

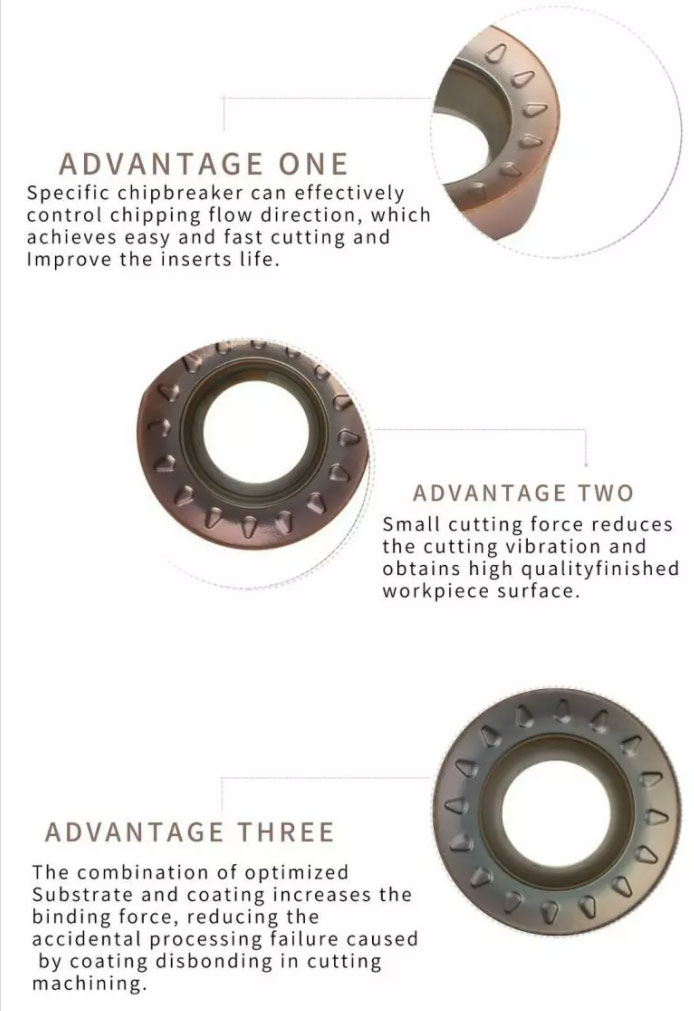

CVD diamond-coated carbide tools offer several advantages over uncoated carbide and PCD tools. A diamond-coated carbide tool can typically manufacture more than 10 times as many parts as an uncoated carbide tool can. CVD technology also makes it possible to coat complex tool shapes, such as inserts with chipgroove geometries. Such shapes are not readily available through PCD technology. Also, CVD diamond in its thick-film form is a cheaper, more effective replacement for PCD composite in brazed tools.

CVD diamond tools have been found to excel in the cutting of green ceramics, graphite- or fiberglass-reinforced composites, brass, bronze, metal-matrix composites (such as A-359 aluminum/SiC and 6061 aluminum/Al2O3), magnesium alloys, plastics, and laminates. Table 1 shows that the hardness of the particulates present in some aluminum alloys is greater than that of tungsten carbide. This leads to rapid tool failure when an uncoated carbide tool is used on these alloys. Diamond, however, because of its extreme hardness, does an excellent job of machining these materials without sacrificing tool life.

Thin-film diamond coatings for cutting tools are typically 0.001" (25µm) thick. The coatings are kept thin to maintain the cutting-edge sharpness. The rake and flank of the tool are both coated. The diamond coating conforms to all geometries, including chipbreaker designs and custom-tool geometries. While a PCD blank can be brazed onto only one corner of an insert, CVD diamond can coat all corners. This allows diamond-coated tools to outperform PCD tools in some tool-life tests. The promise of CVD coating is a cheap, throwaway tool that provides the performance of PCD, while requiring no resharpening of the diamond and the attendant costs of inventory and tracking.

The quality of a CVD diamond coating’s adhesion to the underlying tool surface depends on the tool material. The adhesion of a diamond coating to Si3N4 is good. CVD diamond-coated Si3N4 tools outperform PCD tools in many cutting applications, such as the machining of graphites and polymer composites. While diamond coatings improve the performance of a Si3N4 tool, they cannot overcome some of the inherent shortcomings of Si3N4 itself, such as poor fracture strength. That’s why so much effort in recent years has gone into CVD diamond-coating carbide tools.

Under CVD diamond growth conditions, the cobalt in tungsten carbide tools acts as a catalyst for the formation of weakly bonded carbon. This graphitic layer essentially prevents the adhesion of the diamond to the substrate. One solution to this problem is to diamond coat binderless tungsten-carbide tools. Diamond adhesion to cobalt-free carbide is reliable, leading to excellent cutting performance by the tool. However, the cobalt binder used in a tungsten- carbide tool gives the tool its high fracture strength. Without the cobalt binder, diamond-coated carbide tools aren’t as useful.

When cobalt-enriched carbide tools are coated with CVD diamond, the life of these tools is severely limited by delamination and spalling of the coating. In recent years, however, several companies and research institutions attempted to solve the problem of diamond adhesion to standard carbide grades. Several successful adhesion-promoting treatments have been reported. So far, success has been limited to carbides with a maximum of 6% cobalt, which is C-2 carbide, the most widely used carbide grade. The most successful approach has been to etch the cobalt from the surface layer using wet, electrochemical, or plasma etching techniques. It was found that removing the cobalt from the surface region to a depth of 5µm to 10µm does not significantly weaken the substrate but does dramatically increase adhesion of diamond to the surface.

Currently, most of the major carbide-tool manufacturers possess access to good adhesion technology for CVD diamond on tungsten carbide with cobalt. Tool life in turning applications is now limited by diamond wear—not by brittle substrates, delamination, or spalling. Note, however, that interrupted cutting is still a challenge and work is still being done to improve coating performance in interrupted applications.

Thick-film CVD diamond can be grown to a thickness equal to that of PCD, up to 1mm. PCD is often bought by the tool manufacturer as a blank with a tungsten-carbide backing. It is then cut by EDM into triangular tips (2mm to 5mm thick). Each tip is open-air brazed onto a tool corner. CVD thick-film diamond is also bought as a blank and is laser cut. (Without the cobalt backing or filler, the diamond is strictly an electric insulator, and hence it cannot be EDMed.) CVD diamond can be brazed readily in large quantities using a vacuum furnace.

One advantage CVD thick-film diamond has over PCD is the fact that thick-film is pure, compared to PCD’s diamond/cobalt composition. The resulting performance improvements are listed in Table 2. Over the past two years, researchers have conducted extensive testing of CVD diamond thick-film vs. PCD. Both products have specific advantages, but thick-film is more abrasion-resistant, and more thermally conductive. Also, thick-film has a lower coefficient of friction and better chemical and thermal stability than PCD. PCD is superior in terms of fracture strength.

CVD thick-film diamond also has some distinct manufacturing advantages over PCD. The CVD diamond can be grown on a mirror-smooth surface, typically a silicon wafer or a molybdenum puck. After deposition the diamond can be released from the substrate to yield a mirror-finish top surface for the tool tip. This obviates the top polishing required by PCD. CVD thick-film can be deposited over areas up to 12" in diameter. The versatility and affordability of laser cutting enables custom manufacturing of diamond cutting edges of practically any shape.

The world market for CVD diamond-coated inserts, based on estimates from large tool manufacturers, is $5 million per year. The current PCD world market is $250 million per year. Perhaps the fastest growing demand for diamond tools comes from the automotive sector, which needs the technology for machining hypereutectic aluminum and new brake-pad composites. The projected growth of the aluminum content in U.S. automobiles, shown in Figure 3, is due in part to impending U.S. government regulations concerning fuel efficiency. (More aluminum means lighter cars, which translates into higher fuel efficiency.) Many of the aluminum alloys to be used contain a high percentage of silicon particulates. As shown in Table 1, these particulates may be harder than tungsten carbide and may severely limit carbide tool life. But diamond tools can handle them with comparative ease.

Ultimately, the acceptance of CVD diamond tool products will depend on their performance and price, especially in comparison to PCD tools. The availability of commercial CVD diamond reactors enables both large and small tool houses to compete favorably on both these points with PCD suppliers. For thin-film diamond, the end user now has three options:

1) Buy from one of several tool firms offering diamond-coated tools. These include Crystallume, Kennametal, Norton (Si3N4 tools only), Sandvik, and Teledyne. Typical price for a diamond-coated carbide tool at the IMTS show was $60.

2) Utilize a toll coating service offered by a company that has adhesion technology, such as Crystallume or sp3.

3) Purchase a diamond-coating reactor for in-house coating (ASTeX, Woburn, MA). In terms of profit margin, this option is the most attractive, but it requires access to adhesion technology. Table 3 breaks out the costs for in-house production using a single reactor.

The impact of the availability of CVD diamond reactors on the PCD market is large. Toll houses can now replace PCD with their own in-house manufactured thick-film CVD puck. The added control over a critical supply is a welcome change. CVD is much cheaper to make and cuts more parts in many applications. For example, the cost of manufacturing a 2" by 0.5mm CVD puck can be $300, depending upon sales volume. This represents a significant savings over PCD, which costs about $900 for an identical piece.

The commercial availability of CVD diamond coatings for carbide tools is great news for end users, offering them a chance to cut challenging materials more economically than ever before. Even better news may be the development of inexpensive turnkey diamond-deposition reactors that may permit users to coat their own tools.

About the Author Roy Gat is a research scientist in the diamond and process products group at ASTeX. He is responsible for tool-coating-process development. Stacy Swider is lead reliability engineer, and Edward Kelly is marketing manager at ASTeX.

Substance used for grinding, honing, lapping, superfinishing and polishing. Examples include garnet, emery, corundum, silicon carbide, cubic boron nitride and diamond in various grit sizes.

Substances having metallic properties and being composed of two or more chemical elements of which at least one is a metal.

Aluminum containing specified quantities of alloying elements added to obtain the necessary mechanical and physical properties. Aluminum alloys are divided into two categories: wrought compositions and casting compositions. Some compositions may contain up to 10 alloying elements, but only one or two are the main alloying elements, such as copper, manganese, silicon, magnesium, zinc or tin.

1. Flexible portion of a bandsaw blade. 2. Support material behind the cutting edge of a tool. 3. Base material for coated abrasives.

Cutting tool materials based on aluminum oxide and silicon nitride. Ceramic tools can withstand higher cutting speeds than cemented carbide tools when machining hardened steels, cast irons and high-temperature alloys.

High-temperature (1,000° C or higher), atmosphere-controlled process in which a chemical reaction is induced for the purpose of depositing a coating 2µm to 12µm thick on a tool’s surface. See coated tools; PVD, physical vapor deposition.

Groove or other tool geometry that breaks chips into small fragments as they come off the workpiece. Designed to prevent chips from becoming so long that they are difficult to control, catch in turning parts and cause safety problems.

Carbide and high-speed-steel tools coated with thin layers of aluminum oxide, titanium carbide, titanium nitride, hafnium nitride or other compounds. Coating improves a tool’s resistance to wear, allows higher machining speeds and imparts better finishes. See CVD, chemical vapor deposition; PVD, physical vapor deposition.

Materials composed of different elements, with one element normally embedded in another, held together by a compatible binder.

Tangential velocity on the surface of the tool or workpiece at the cutting interface. The formula for cutting speed (sfm) is tool diameter 5 0.26 5 spindle speed (rpm). The formula for feed per tooth (fpt) is table feed (ipm)/number of flutes/spindle speed (rpm). The formula for spindle speed (rpm) is cutting speed (sfm) 5 3.82/tool diameter. The formula for table feed (ipm) is feed per tooth (ftp) 5 number of tool flutes 5 spindle speed (rpm).

Process that vaporizes conductive materials by controlled application of pulsed electrical current that flows between a workpiece and electrode (tool) in a dielectric fluid. Permits machining shapes to tight accuracies without the internal stresses conventional machining often generates. Useful in diemaking.

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

Hardness is a measure of the resistance of a material to surface indentation or abrasion. There is no absolute scale for hardness. In order to express hardness quantitatively, each type of test has its own scale, which defines hardness. Indentation hardness obtained through static methods is measured by Brinell, Rockwell, Vickers and Knoop tests. Hardness without indentation is measured by a dynamic method, known as the Scleroscope test.

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

Abrasive process that improves surface finish and blends contours. Abrasive particles attached to a flexible backing abrade the workpiece.

Cutting tool material consisting of polycrystalline cubic boron nitride with a metallic or ceramic binder. PCBN is available either as a tip brazed to a carbide insert carrier or as a solid insert. Primarily used for cutting hardened ferrous alloys.

Cutting tool material consisting of natural or synthetic diamond crystals bonded together under high pressure at elevated temperatures. PCD is available as a tip brazed to a carbide insert carrier. Used for machining nonferrous alloys and nonmetallic materials at high cutting speeds.

Angle of inclination between the face of the cutting tool and the workpiece. If the face of the tool lies in a plane through the axis of the workpiece, the tool is said to have a neutral, or zero, rake. If the inclination of the tool face makes the cutting edge more acute than when the rake angle is zero, the rake is positive. If the inclination of the tool face makes the cutting edge less acute or more blunt than when the rake angle is zero, the rake is negative.

Extremely hard material added to tungsten carbide to reduce cratering and built-up edge. Also used as a tool coating. See coated tools.

Added to titanium-carbide tooling to permit machining of hard metals at high speeds. Also used as a tool coating. See coated tools.

Intermetallic compound consisting of equal parts, by atomic weight, of tungsten and carbon. Sometimes tungsten carbide is used in reference to the cemented tungsten carbide material with cobalt added and/or with titanium carbide or tantalum carbide added. Thus, the tungsten carbide may be used to refer to pure tungsten carbide as well as co-bonded tungsten carbide, which may or may not contain added titanium carbide and/or tantalum carbide.

Workpiece is held in a chuck, mounted on a face plate or secured between centers and rotated while a cutting tool, normally a single-point tool, is fed into it along its periphery or across its end or face. Takes the form of straight turning (cutting along the periphery of the workpiece); taper turning (creating a taper); step turning (turning different-size diameters on the same work); chamfering (beveling an edge or shoulder); facing (cutting on an end); turning threads (usually external but can be internal); roughing (high-volume metal removal); and finishing (final light cuts). Performed on lathes, turning centers, chucking machines, automatic screw machines and similar machines.

Roy Gat is a research scientist in the diamond and process products group at ASTeX. He is responsible for tool-coating-process development.

Ccmt09t304 Vp15tf © Copyright 1995 - 2024. Cutting Tool Engineering. All rights reserved.