Many customers have asked us whether the 3500 Machinery Monitoring System is an “obsolete” product. Our response is that while the Orbit 60 -- an integrated machine condition monitoring and protection system -- is recommended for all new installations post 2020 wherever suited and represents increased functionality and value, the 3500-product line remains fully supported, even as it passes its 24th birthday. Why? Very simply, 3500 remains a viable, reliable machinery protection system with worldwide acceptance. Globally, more than eighty thousand 3500 Systems are deployed, and ~5,000 new systems being installed annually, we have a strong commitment to support our customers rather than institute a forced obsolescence program.

The Bently Nevada 3500 system represents over 60 years of Bently Nevada machinery protection and condition monitoring domain knowledge and best practice methodology built in to a highly flexible and scalable rack-based platform. Over 20 years of continuous product development and enhancement has produced a finely tuned rack-based system that is focused on reliably protecting critical machinery. In addition, it enables the use of Bently Nevada’s System 1†, advanced machine protection and diagnostic software, to perform detailed and accurate machinery diagnostics critical to an effective condition-based maintenance program. ge ic697chs770

Here is a quick comparative overview highlighting some key enhancements with Orbit 60 helping you make the best decision for your application and organization overall.

The 3500 product is manufactured, tested, and assembled in Minden, Nevada which is part of the heritage of quality and reliability in every Bently Nevada product. Electronic manufacturing capabilities in Minden include over $10MM recent investments that include PCBA prototyping, and 3 new state of the art PCBA manufacturing lines that include the latest in inspection, tracking, and testing capabilities.

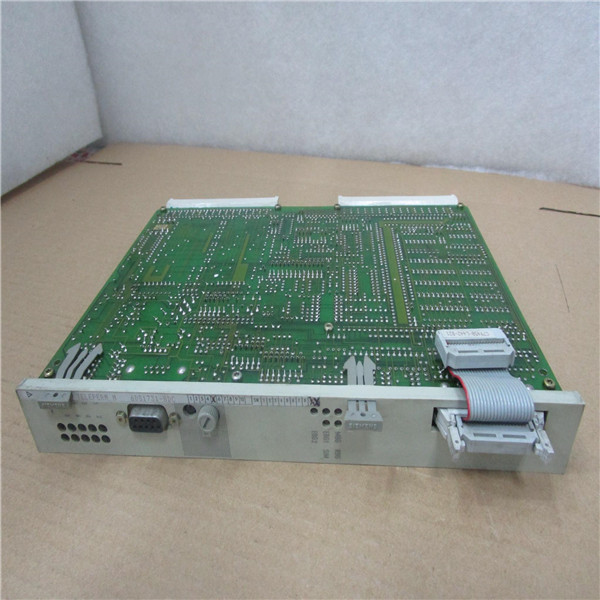

Bently Nevada is committed to support our 3500 installed-base across globe and made a significant (multi million dollar) Investment in 2016 & 2017 to completely refresh all the electronics, boards, and layout on the PCBA 3500 modules to meet RoHS standards. The green boards have now been replaced with the blue boards for a lead-free product line. The improved design of boards and new manufacturing infrastructure has helped in nearly 100% automation of part placements and 3D X-ray inspection, laser profiling of solder deposits. Along with this there is continual focus on improving the testing processes to ensure premium quality products.

In addition, Bently Nevada has taken proactive steps to manage component and tools obsolescence and have solidified critical component’s lifecycle management contracts with suppliers, as well as, Firmware documentation and libraries were completed. Currently 3500 rack configuration software is being refreshed to take advantages of newer software technologies available.

foxboro p0916aw Today’s Machinery Condition Monitoring: From Siloed and Optional to Integrated