Hi, what are you looking for?

NWRA opposes proposed change to biogas tax credit Recycled Plastic Extruder

The largest clean energy project in U.S. history closes $11 billion, starts full construction

Veolia North America breaks ground on solar array at waste treatment facility

Two renewable natural gas facilities operating in Upper Piedmont, Foothills landfills

Nucor and Helion to develop fusion power plant

Nearly $1 billion in grants available for clean, heavy-duty vehicles

EPA finalizes Greenhouse Gas Standards for heavy-duty vehicles

GM fuel cell pilot program extends beyond hydrogen trucks

Nearly $1 billion in grants available for clean heavy-duty vehicles

EPA finalizes Greenhouse Gas Standards for heavy-duty vehicles

Inteplast Group acquires Brown Paper Goods

Timken names new president and chief executive officer

WM elects Bené to board of directors

Schupan appoints Reid as VP of marketing-international

CARE names Person and Recycler of the Year

U.S. Green Building Council releases LEED v5 for comment

California carpet recycling rate surpasses goal

U.S. Green Building Council names top 10 U.S. states for green building

Thomas Brown to lead The Associated General Contractors Of America as its new president

DOE recommends grant award for ERI to expand electronic recycling

Samsung Electronics to establish semi-conductor ecosystem in Central Texas

Closed-loop recycling in the EV market

DOE recommends grant award for ERI to expand electronic recycling

Element 25 secures U.S. site for HPMSM refinery in Louisiana

EQUIPMENT SPOTLIGHT | MAY 2024 Material Handlers

EQUIPMENT SPOTLIGHT | APRIL 2024 Crushers/Loggers

EQUIPMENT SPOTLIGHT | MARCH 2024 Eddy Currents

CARE names Recycler of the Year

ISRI rebrands as The Recycled Materials Association

ISRI rebrands as The Recycled Materials Association

Application period opens for foam recycling grants

Veolia North America joins forces with Professional Pickleball Association as sustainability provider

GRF to award grants to divert glass from landfills

Murphy Road Recycling receives Gold for All American MRF Glass Certification

Pennsylvania’s Traveling Glass Recycling Bin Program expands

Waco, Texas brings back glass recycling bins

Arglass invests to expand glass recycling capacity

Nippon Steel receives non-U.S. regulatory approvals to acquire U.S. Steel

Arrests made in copper thefts

Steel import permit applications decrease

EGLE seeks proposals for organics infrastructure grant program

EGLE seeks proposals for organics infrastructure grant program

U.S. Senate passes bills to improve recycling and increase composting

U.S. Senate passes bills to improve recycling and increase composting

The Kroger Co. Zero Hunger awards $1M grant to Feeding America

AF&PA releases paper reports

AF&PA sets Advocacy Agenda for 2024

Brian Gaughan joins Mid America Paper Recycling

Paper mill in Vermont to close

AF&PA sets Advocacy Agenda for 2024

Plastics Industry Association honors sustainability innovation award winners

BASF launches ChemCycling in the United States

PLASTICS releases Bioplastics Market Watch Report

PLASTICS launches Flexible Film Recycling Alliance

TOMRA achieves industry first with food-grade plastics sorting solution

Liberty Tire Recycling applauds tire crumb rubber study conducted in U.S.

Firestone Liberia earns historic certification

Tire program cleans up over 507,000 tires

Higher 2024 tire shipments predicted for U.S. market

Shred-Tech acquires CM Shredders by parent The Heico Companies

Titan Environmental Solutions acquires Standard Waste Services

ReMA Launches ESG Toolkit for Members

Grant helps fund a new recycling facility

Fees to be charged for recycling contamination

Amandus Kahl Mike Curci 470-421-0970 www.akahl.com/en

American Pulverizer Company James Holder 314-781-6100 www.ampulverizer.com

Avian Recycling System Andy Gu 630-687-9876 www.avianusa.com

BHS-Sonthofen Inc. Tom Adams 704-845-1190 www.bhs-filtration.com

Bruno Folcieri Srl George Dadiani 626-602-6696 www.folcieri.us

Cumberland Size Reduction Michael Tuchalski 262-641-8600 www.cumberlandplastics.com

Eldan Recycling Carsten Nielsen 716-731-4900 www.eldan-recycling.com

EREMA North America, Inc. Robert Wahlmueller 978-356-3771 www.erema.com/us

Foremost Machine Builders Drew Schmid 973-227-0700 www.foremostmachine.com

Franklin Miller Inc.Korkmaz Oz 800-932-0599 www.franklinmiller.com

Herbold Meckesheim USA David Lefrancois 401-597-5500 www.herboldusa.com

Hosokawa Polymer Systems John Ocone 860-828-0541 www.polysys.com

Rapid Granulator Jim Hoffman 724-584-5220 www.rapidgranulator.com

Rotogran International Inc. Mike Cyr 905-738-0101 www.rotogran.com

Transparency Market Research defines components of the plastics recycling market as: PET, PP, HDPE, LDPE, PS, PVC and others – as well as plastics from packaging; automotive, construction, textiles and others. Last year, the same source quantified the global industry value of those materials as $45.5 billion and, that value is expected to reach $129 billion by 2035.

Recyclers that require the tools to process this wide range of materials are responding to a variety of global factors, including: increased awareness of environmental issues, a rise in governmental focus on sustainability and evolving regulation geared toward plastic waste reduction. Entities that generate plastic are also being pressed to reduce output as much as possible. As closed loop product design should include optimal recyclability, it may also involve various recycling equipment types – and granulators may be part of that mix.

The Amandus Kahl pan grinder mill, unique for processing up to 10 tons per hour, also features gravity-fed mechanisms, a horizontal flat-die configuration for size reduction and adaptability to various material types. “A notable example of engineering and innovation in the field of size reduction technology, these mills are renowned for their efficiency, durability, and versatility. Our products embody German engineering excellence and with over 100 years of expertise, Amandus Kahl specializes in providing solutions for size reduction of plastics, paper, and other materials,” commented Mike Curci, Amandus Kahl USA.

According to Curci, the efficient size reduction technology Amandus Kahl employs addresses several key industry challenges, including energy consumption and material handling. Unlike traditional methods, Amanadus Kahl’s size reduction in the pan grinder mill does not require additional air filtering or explosion protection systems (ATEX), making it a safer and more cost-efficient solution. This approach not only facilitates the handling of bulky and fibrous materials by increasing their bulk density but also enhances the overall energy efficiency of the size reduction process, a critical factor in the recycling industry. As the demand for renewable energy and sustainable recycling methods grow, Amandus Kahl’s innovations, particularly in size reduction and flat-die technology, position the company at the forefront of the industry.

“Our commitment to improving energy efficiency and refining the size reduction process mirrors the global trend toward more environmentally friendly and cost-effective size reduction solutions. Amandus Kahl’s developments in size reduction technology reflect a deep understanding of the industry’s future direction, focusing on flexibility, efficiency, and sustainability. Our firm’s ambitions stretch far beyond technological advancements. We’re dedicated to playing a pivotal role in the global transition towards sustainable energy and recycling practices. With a particular focus on plastic recycling and through pushing the limits of size reduction technology and prioritizing environmental responsibility, Amandus Kahl is determined to lead the shift toward a more sustainable future,” Curci said.

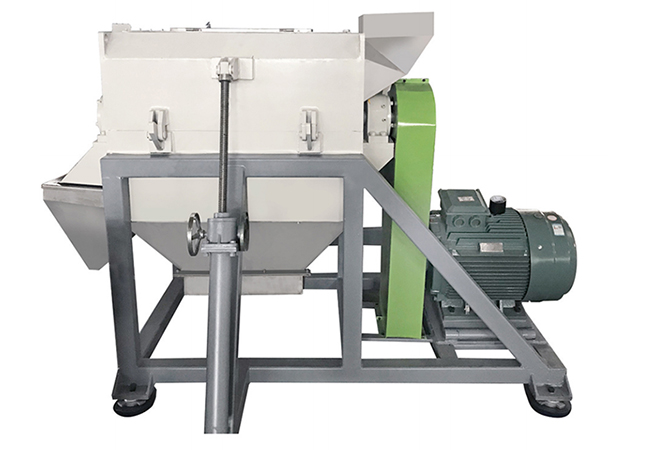

As a production-oriented enterprise specializing in the manufacture of high-quality environment-friendly plastic recycling equipment, Avian Recycling System product lines encompass a variety of machines, including high-speed plastic granulators, shredders, pulverizers, agglomerators, and professional, complete PET plastic washing lines. Andy Gu, operations vice president, reported that the firm has been “a leading global recycling equipment manufacturer since 1962”. Avian provides recycling washing lines, PET bottle recycling washing from 3 to 12T/hr., HDPE bottle recycling washing from 3 to 9T/hr., film recycling washing from 1 to 2T/hr., granulators from 10 to 500 hp., shredders from 30 to 400hp, aglomerators (models PA400 and PA600) and pulverizers.

The U.S. branch of Avian Recycling System operates a manufacturing, distribution, and service facility located in West Chicago. Serving as a trusted supplier to the plastics manufacturing and recycling industry, Avian’s clientele also includes companies in the automotive, packaging, construction, furniture, and textile industries,” Gu stated.

Managing partner George Dadiani of JV Explore is also the North American representative for granulator manufacturer, Bruno Folcieri. He stated that “for over 60 years, Bruno Folcieri machines have carried a flawless reputation for reliability. These machines are considered best in class due to their precise engineering, provided to meet the needs of their customers. The firm is a leader in building the most reliable equipment for the recycling of PET and polyolefins such as AMUT and technofer and this also includes Bruno Folcieri granulators as part of washing lines. Well known in the U.S., I am happy to help them in further expanding their presence in the North American market.”

Citing an example of a Canadian client, Dadiani noted that the firm’s Bruno Folcieri granulator has been operating there for over 37 years. “Operating alongside it is a 25 year old machine, also running flawlessly. About 75 percent of companies that bought their first granulator from Folcieri come back to Folcieri for their 2nd, 3rd – and more – as the advantages of these machines are crystal clear. They include: lowest operating cost, record breaking longevity, the fastest and easiest maintenance in the market, unbreakable rotors and cutting chambers and unique design solutions.

“We are especially enthusiastic about the strength of Bruno Folcieri machines in the safe and reliable granulation of large diameter pipes, up to 2m in size. This product is typically made of the most tough to handle plastics, such as high impact PP, for example. No other granulator on the market offers this capability. These Bruno Folcieri machines typically run for decades without any issues for countless European clients. As we offer such solutions to North American companies, we are off and running as we respond to many who have contacted us.”

Published in the June 2024 Edition of American Recycler News

Add Your Organization The Breast Cancer Research Foundation Donate Your Vehicle to BCRF and Make a Difference! Help defeat breast cancer with your tax...

Plastic Pipes Making Machine Privacy Policy | Terms of Use 877-777-0043 • Phone 419-931-0737 • Fax 419-931-0740 • 28300 Kensington Ln., Ste. 500, Maumee, Ohio 43537 © Copyright American Recycler News, Inc. All rights reserved. Any reproduction of content requires written permission.