As a farmer, you know that ensuring accurate seed depth is essential for a successful harvest. One often overlooked aspect of seeders is the weight of the equipment and the management of upward and downward forces while moving throughout the field. However, once you've addressed that, the next thing to look at is the depth adjustment components and their wear parts.

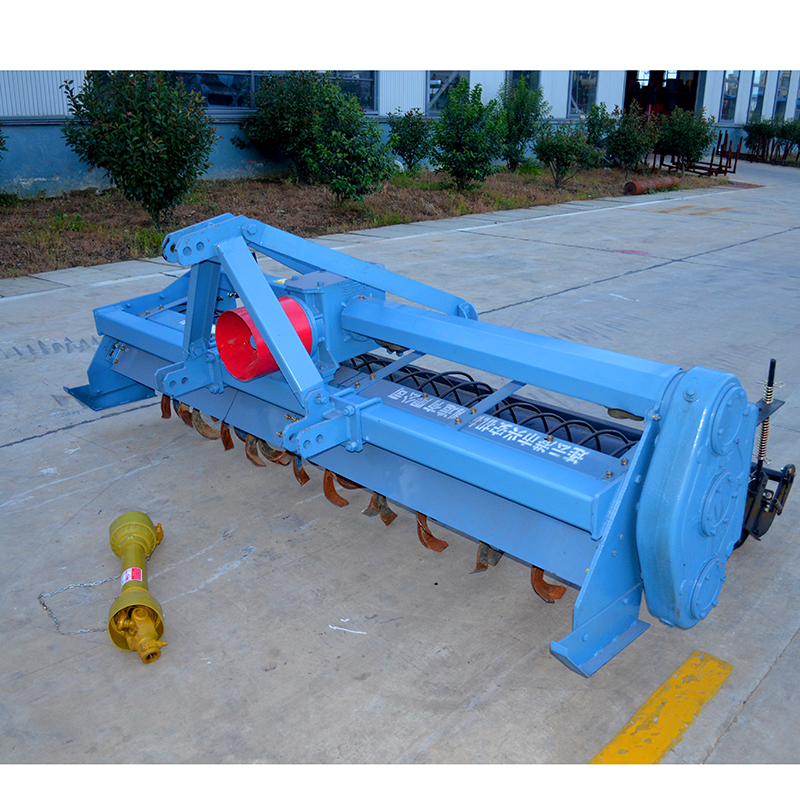

The first component to examine is the depth arm, which is where you adjust the in-ground depth of your seeds. Soybean Planter Machine Seeder

Check for wear on the indexes of the cover, which can impact the accuracy of the depth adjustment.

The spindle that runs inside the opening arm is another component that requires attention. Any debris or dust that gets into the spindle with the grease can cause wear and eventually lead to the spindle seizing up inside the housing, making proper adjustments impossible.

If you have a John Deere OEM depth adjust arm, look for wear inside the jaw. The constant chattering within the gauge wheel linkage assembly can cause the entire component to wear out, leading to changes in seeding depths.

The primary cause of wear inside this arm is usually inadequate downforce or insufficient ballast. You need to have sufficient downforce on the gauge wheel constantly pressing firmly against the soil surface to avoid unnecessary wear and tear.

Remember, maintaining accurate depth adjustments is crucial for the best yields. Keep your seeder in top condition by regularly checking these components and replacing them as necessary.

Partner with a Precision Planting Dealer to achieve your best yields and avoid the regret that comes from avoidable yield loss caused by a lack of maintenance. Find your local Precision Planting Premier Dealer at PlanterExpert.com.

To watch videos of all recommended annual maintenance checks, visit PrecisionPlanting.com/seedermaintenance.

Download the free Seeder Maintenance Guide. This guide includes a 1-sheet checklist, links directing you to the corresponding videos, and an overview of 8 key maintenance areas on your seeder.

The Seeder Maintenance series is brought to you by Precision Planting.

For farmers who believe in better. Believing in better is a mindset to pursue excellence in everything you do. It’s welcoming opportunities to improve your farm and knowing that your best season is simply a starting point for this season. Precision Planting is for farmers like you who Believe in Better.

Get full access NOW to the most comprehensive, powerful and easy-to-use online resource for no-tillage practices. Just one good idea will pay for your subscription hundreds of times over.

Download these helpful knowledge building tools

On this episode of Conservation Ag Update, brought to you by Montag Manufacturing, Amherst, Neb., no-tiller Jared Kenney shares a key lesson learned from one of his biggest planting mistakes, and how it helped him break the 300-bushel barrier twice. Plus, “the father of biological agriculture,” Gary Zimmer shares his top 4 nutrients for a better crop.

Soybean Planter Machine Seeder Design, CMS, Hosting & Web Development :: ePublishing