Aashi Mishra, senior content writer at Research Nester, spotlights the aluminium foil market, its applications and limitations.

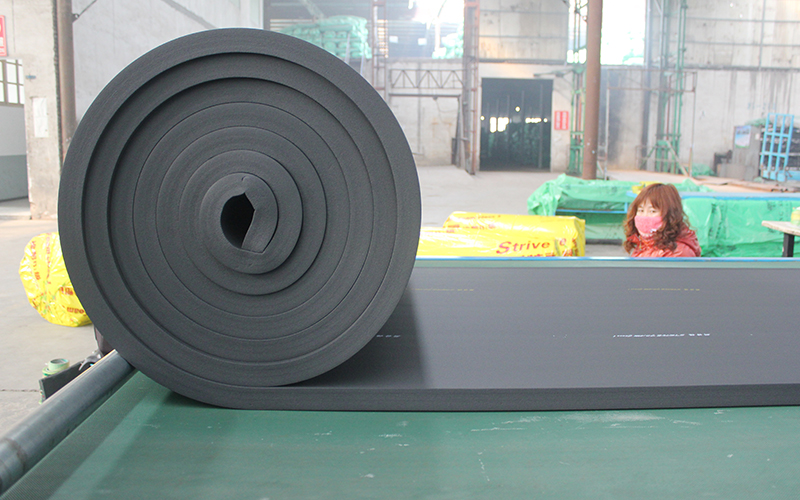

Aluminium foil is popular packaging material in the food and beverages, aeronautical, transport, medical devices, and pharmaceutical industries. Owing to its high malleability, it can be folded, molded, and easily rolled as per the need of packaging. High Temperature Insulation Materials

You will receive an email shortly. Please check your inbox to download the Report.

The gold standard of business intelligence.

By downloading this case study, you acknowledge that GlobalData may share your information with GlobalData and that your personal data will be used as described in their Privacy Policy

Tick here to opt out of curated industry news, reports, and event updates

Visit our Privacy Policy for more information about our services, how GlobalData may use, process and share your personal data, including information on your rights in respect of your personal data and how you can unsubscribe from future marketing communications. Our services are intended for corporate subscribers and you warrant that the email address submitted is your corporate email address.

The intrinsic properties of aluminium foil enable it to transform into paper wraps, containers, tablet packs, and others. It has great reflectance, which finds its application in both decorative and functional areas.

Access the most comprehensive Company Profiles on the market, powered by GlobalData. Save hours of research. Gain competitive edge.

Your download email will arrive shortly

We are confident about the unique quality of our Company Profiles. However, we want you to make the most beneficial decision for your business, so we offer a free sample that you can download by submitting the below form

The use of aluminium foil all across the world is reportedly rising at the rate of 4% every year. In 2018, around 5m tonnes of aluminium foil was utilised worldwide, and it is expected to surpass 7m tonnes in the next two years, i.e. by 2025. China is a key user of aluminium foil; it holds a share of 46% of the world’s usage.

The most important application of aluminium foil is insulation. It acts as a thermal insulation layer in pipes and ducts, and in the construction industry it is employed as a vapour barrier by topping it as a layer for insulating material, such as foam insulation and rock wool.

Aluminium foil is a very thin sheet which can provide great protection against light and oxygen. Owing to these properties, it is extensively used in primary packaging for products that develop sensitivity to moisture, microorganism, and oxygen over time.

It is one of the most preferred packaging materials for beverages due to its longevity than other alternatives. For packaging 1000g of a liquid, only 1.5 grams of aluminium foil is required in 28 grams of lamination. This 1.5 grams ensures the protection, better life, and reliability of the carton.

Aluminium foil is rapidly becoming popular in food and beverage packaging and is projected to play an important role in the industry’s expansion. It is frequently used in packaging dairy products, candy, and coffee. It is the safest option for food packaging, and provides various benefits to the food industry:

However, aluminium foil is not recommended for salty or acidic foods. Aluminium is prone to leaching into food with larger concentrations, in acidic, salts, and liquid food solutions such as lemon and tomato juice. If these products are stored in direct contact with aluminium ions, they may be harmed. To reap the benefits of aluminium without the risk of dissolving aluminum ions, employ a composite film liner.

Industrial items must be shielded from odors, pollutants, and other detrimental environmental conditions. To protect product integrity and adhere to OEM standards, these products should be packed in flexible foil packaging.

Aluminium foil is a strong and durable material that can withstand various handling and transportation conditions. It provides protection against tearing, puncturing, and other forms of damage, ensuring the integrity of the packaged products.

Pharmaceuticals and other medical commodities demand a high level of product safety; medical-grade foil thicknesses of 20, 25, and 30 are most typically used in pharmaceutical blister packing. Aluminium packaging offers numerous advantages in the medical field:

Since the pandemic, the prices of shipping have spiked in all areas of the supply chain. Business owners understand the significance of just a few ounces saved per shipment. In such circumstances, aluminium foil decreases shipment weight owing to its compact and lightweight characteristics. Moreover, it is super light, since a 6 mil aluminium foil covering makes a lightweight pack completely immune to moisture, light taint, and gases while maintaining carton rigidity.

In terms of weight, plastic is a rival for aluminium foil. However, the thickness of the aluminium foil is thinner, decreasing product weight and transportation expenses.

China has been in the aluminium foil industry for more than 90 years. It is the world’s largest producer and exporter of the product.

The country has around 157 aluminium foil companies, and produces about 4050Kt aluminum foil. Out of all the total exports in the world, China is responsible for around 70% of aluminum foil.

The major dominance of China in the industry resulted in trade restrictions from various countries, such as Mexico, Turkey, the United States, and others. Pertaining to all these restrictions, China’s aluminium foil exports declined to 1.2m tonnes in 2020, a -4.9% decrease from 2019. Aluminium foil exports fell from $4bn in 2019 to $3.8bn in 2020.

While aluminium foil packaging offers many advantages, there are limitations that also need to be considered.

Aluminium foil packaging is usually prone to punctures and tears, especially if it comes into touch with sharp or pointed items. If the foil is perforated even slightly, it can undermine the package’s integrity thus decreasing its effectiveness as a barrier against moisture, light, or pollutants.

Aluminium foil is not translucent, which means that the contents cannot be seen without unwrapping or opening the package. This constraint can be a disadvantage in situations requiring visual assessment or identification of the packaged product.

Unless specifically labeled as microwave-safe, aluminium foil should not be used in microwave ovens. Aluminium’s metal characteristics can induce arcing, which might harm the microwave or cause a fire hazard.

Aluminium is sustainable due to its abundant availability, durability, and proclivity to be reprocessed at extremely cheap energy costs.

The energy required to manufacture aluminium is captured in the metal. Remelting aluminum for the production of metal requires only 5% of the original energy. As a result, 95% of the initial energy investment is conserved in metal.

Aluminium foil packaging accounts for a negligible fraction of overall home garbage which is less than 0.5%, and the aluminum industry is eager to recover this precious raw material.

Over the years, a lot of financial resources have been invested in finding new ways to make sustainable aluminium. For instance, a recent collaboration in the beverage industry saw Amcor Capsules and Aludium join forces to introduce low-carbon footprint aluminium.

According to the US Energy Information Agency, around 60% of aluminium produced in the United States is recycled. Moreover, studies have shown, recycling 1 tonne of aluminium preserves approximately 14,000kWh of electricity, which is enough to power a 100-watt bulb for more than 140,000 hours. Aluminium is one of the most valuable recyclable resources, and it takes just 60 days to recycle old foil into new aluminum.

Aluminium foil excels in every industry, from tins, packets, sachets, and to large-scale industrial packaging. The versatility of aluminium foil makes it the most suitable product to be used in unfavorable conditions, such as high temperature, large-distance transportation, increased humidity, and others. It is a promising product when in use and even when it is discarded.

About the author: Aashi Mishra is a senior content writer at Research Nester.

You will receive an email shortly. Please check your inbox to download the Report.

By downloading this case study, you acknowledge that GlobalData may share your information with GlobalData and that your personal data will be used as described in their Privacy Policy

Tick here to opt out of curated industry news, reports, and event updates

Visit our Privacy Policy for more information about our services, how GlobalData may use, process and share your personal data, including information on your rights in respect of your personal data and how you can unsubscribe from future marketing communications. Our services are intended for corporate subscribers and you warrant that the email address submitted is your corporate email address.

Give your business an edge with our leading industry insights.

The gold standard of business intelligence.

Give your business an edge with our leading industry insights.

Give your business an edge with our leading industry insights.

Inside Packaging : Packaging Gateway Focus (monthly)

I consent to Verdict Media Limited collecting my details provided via this form in accordance with Privacy Policy

View all newsletters from across the GlobalData Media network.

Phenolic Board The leading site for news and procurement in the packaging industry