All Images Source: ZEISS Industrial Quality Solutions

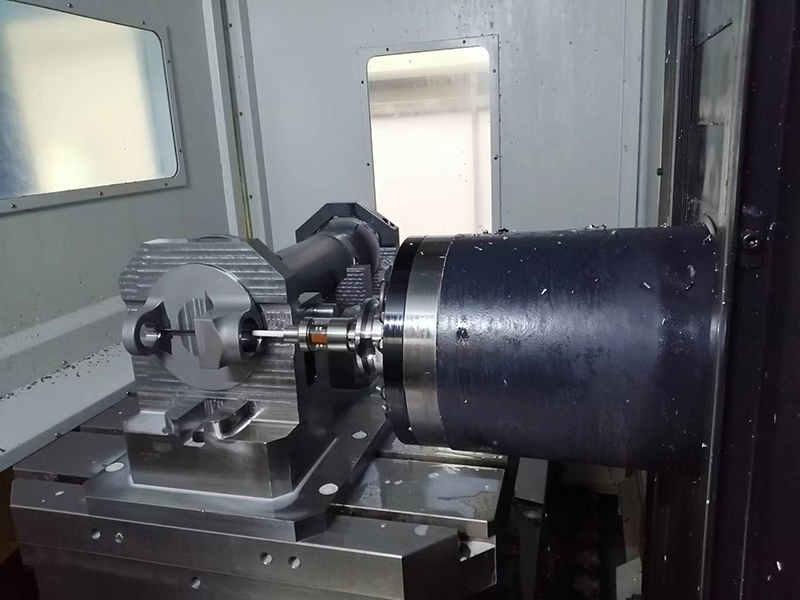

Reliable measuring results from coordinate measuring machines (CMMs) are critical to monitoring manufacturing processes and delivering high-quality parts. Absolute confidence in part quality can only be achieved by keeping the measuring uncertainty at a minimum. Turret Lathe

Styli and probe extensions can provide that certainty for most measurements. However, deep boreholes and hard-to-access features present challenges.

Don’t sacrifice quality by using the wrong styli and probe extensions. Find the right tools made from the right materials for your quality needs.

Probe heads mount onto the arm and styli mount directly to the head of a CMM. As Matt Danford of Modern Machine Shop explains, some CMM scanning heads articulate on their own and some require extensions. Extensions can be found on all standard machines and come in a variety of types.

“Today, a wide selection of CMM probe heads are offered from fixed heads, indexing heads to continuous motion heads,” says Metrology News. “The fixed probe head is still used on extremely high accuracy CMMs and is also particularly useful for carrying long extension bars needed to probe and scan deep internal part features.”

These accessories increase the stylus range and enable optimal access to complex or large parts. Extensions are especially beneficial on fixed probe heads to access difficult-to-reach features deep into cavities or underneath parts.

Extensions have a direct influence on the measuring uncertainty of an overall metrology system. Consequently, the accuracy of what a CMM can achieve, according to specifications, will only worsen when using unsuitable extensions.

Extension performance can be challenged by three determining factors:

Operators should also be aware of best practices when using extensions for both styli and probes. As the National Physical Laboratory explains, “Manufacturers of probe heads and accessories generally specify maximum recommended lengths for probe extensions. Using extensions that exceed these lengths may seriously affect the accuracy and repeatability of the probe head readings.”

The desired result with any quality assurance solution is more consistent measurement results. Choosing the right material for stylus extensions can provide greater stability under changing conditions.

One quality that must be considered is a low coefficient of thermal expansion. Thermal growth is length-dependent, especially with long styli and extensions.

There are many choices for extension materials, and each option is affected by temperature changes in distinct ways. These materials include aluminum alloy, titanium and carbon fiber.

Aluminum was the dominant material decades ago when metrology was mostly conducted in quality labs. New materials were needed as quality assurance and control moved to the production line. Labs were temperature-controlled, but aluminum doesn’t handle temperature changes well and is ill-suited for production-line metrology.

Where metal is needed — for joints, knuckles and so on — titanium offers the best combination of light weight, strength, thermal and structural stability, and density. “But titanium extensions, for weight reasons, had to be reduced in diameter and wall thickness to be comparable to aluminum extensions,” says Jörg Esswein, head of product management for accessories at ZEISS Industrial Quality Solutions. “This reduction leads to loss of rigidity.”

Carbon fiber is the most common material and best option for long styli and extensions. The polymer is stiff, lightweight, has high flexural strength and, because of its thermal stability, the benefits eclipse other materials like aluminum, stainless steel, steel, titanium and ceramic.

Even with their unique advantages, all three materials — aluminum, titanium and even some carbon fiber — may not have the right combination of properties to guarantee the best results from extensions.

It’s important to find an extension portfolio that delivers the perfect combination of material factors. Extension suites should be customized for the varying accuracy requirements of different CMMs. These extensions would always keep accuracy at the highest possible level in combination with a very good price-performance ratio.

Using the right carbon fiber extensions can decrease the influence of the extension on the CMM measuring uncertainty by up to 5 times compared to titanium. Users would also gain increased productivity as significantly higher scanning speeds while maintaining the same level of accuracy are possible thanks to the increased static stiffness. As well, increased temperature resistance can make the extensions suitable for all measuring environments.

Ideally there would be three accuracy levels, based on requirements.

You need a complete carbon fiber extension portfolio that measures up to your accuracy requirements. Ideally, these would be tailored to fit your CMM. Get maximum accuracy and optimal performance without burdening your budget.

ZEISS Industrial Quality Solutions. For more information, email [email protected] or visit zeiss.com/metrology.

You must have JavaScript enabled to enjoy a limited number of articles over the next 30 days.

Sponsored Content is a special paid section where industry companies provide high quality, objective, non-commercial content around topics of interest to the Quality audience. All Sponsored Content is supplied by the advertising company and any opinions expressed in this article are those of the author and not necessarily reflect the views of Quality or its parent company, BNP Media. Interested in participating in our Sponsored Content section? Contact your local rep!

On Demand Join this webinar to learn how companies of all sizes are adopting easy-to-use cobots to overcome the labor shortage, handle multi-shift operations, scale production on-the-fly, and solve many other challenges.

Join us for an exciting webinar where we will introduce state-of-the-art Handheld 3D Scanners designed to streamline your quality inspection process, offering speed, agility, and simplicity.

Copyright ©2024. All Rights Reserved BNP Media.

Cnc Table Design, CMS, Hosting & Web Development :: ePublishing