Hi, what are you looking for?

NWRA opposes proposed change to biogas tax credit Grass Baler

The largest clean energy project in U.S. history closes $11 billion, starts full construction

Veolia North America breaks ground on solar array at waste treatment facility

Two renewable natural gas facilities operating in Upper Piedmont, Foothills landfills

Nucor and Helion to develop fusion power plant

SAS Forks expands with DRKhorse division

EGLE awards funding for the Lake Michigan Circuit EV charging network

Organize your COA to CYA: Most small business owners don’t read their P&L

EGLE awards funding for EV charging network

Komatsu to acquire American Battery Solutions

Goodyear names new vice president of commercial business

Dan Quam joins Brokk as parts manager

OPENLANE to acquire Manheim Canada

Robert Bunting nominated as interim treasurer of PEMA

Illinois passes new law for statewide household paint recycling program

MUSHROOMS USED TO DECARBONIZE CONSTRUCTION WASTE

Three out of four metro areas add construction jobs from March 2021 to March 2022

Recycler of the year named

Safe dismantling of electric vehicles

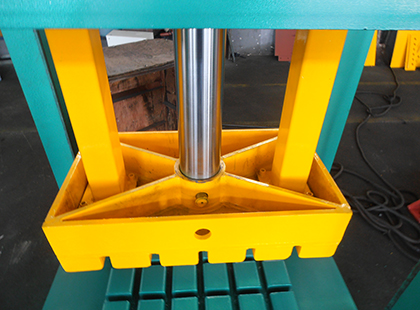

EQUIPMENT SPOTLIGHT | FEBRUARY 2024 Derimmers/Shears

New Survey: Americans are concerned about electric vehicle battery disposal

BASF and Stena Recycling partner to recycle EV batteries

ACE Green delivers emissions-free lead recycling technology to ACME

EQUIPMENT SPOTLIGHT | FEBRUARY 2024 Derimmers/Shears

EQUIPMENT SPOTLIGHT | NOVEMBER 2023 Primary Reduction

ISRI Board to consider changes to recycled nonferrous specifications

Springfield MRF advisory board wins award

Fatality rate for waste and recycling industry declines in 2022

American Environmental Partners Inc. (AEPT) has net loss results for the third quarter of 2023

ISRI Opens Application Process for Prestigious 2024 Design for Recycling® Award

MRF glass used as alternative daily cover

City of Port Angeles to Reinstate Glass Recycling

THE EVOLVING GLASS RECYCLING INDUSTRY

Glass recycling to improve with support of foundation grants

Successful recycling programs can grow from simple, individual efforts

Novelis enters agreement with Ardagh Metal for aluminum can sheet

MetalX selects Defiance, Ohio site for aluminum recycling campus

TimkenSteel to change name to Metallus Inc.

Elemental Holding enters partnership with Mitsubishi for platinum group metals recycling

International Shipbreaking only U.S. recycling yard to be approved by EU Commission

New federal grants are solution for food waste

EPA awards Ontario, California grant to upgrade recycling infrastructure

Survey provides insight on recycling

AF&PA Releases Paper Reports

AF&PA releases quarterly reports

AF&PA releases paper reports

Life cycle assessment reinforces corrugated packaging industry’s sustainability leadership

Amcor launches curbside-recyclable paper packaging in North America

Report shows bottle-to-bottle circularity rising

Neste doubled the amount of waste plastic processed during 2023

Three partners are changing the narrative in plastic recycling at Site Zero

The Government of Canada is seeking feedback on developing a federal plastics registry

Proposed new legislation aims to restrict plastic foam foodware

Bridgestone HosePower acquires Cline Hose & Hydraulics

Youngstown, Ohio adopts moratorium on pyrolysis of tires

Michelin alleges infringement of intellectual property rights protecting BFGoodrich All Terrain T/A K02 tire

2024 Tire Recycling Conference to focus on accelerating growth in tire recycling markets

Allied Waste resolves clean air act violations at its Niagara Falls Landfill

Pennsylvania DEP issues approval for leachate evaporation system at landfill

NY DEC releases the finalization of the New York State Solid Waste Plan

Report shows only 21 percent of residential recyclables are captured

Waste and recycling industry sees decline in rate of fatalities

Al-jon by C&C Mfg Curt Spry 641-670-0541 www.aljon.com

Imabe César Benitez 918 71 70 11 www.imabeiberica.com

Iron Ax John Kitchens 478-252-0022 www.ironax.com

OverBuilt Steve Besch 800-548-6469 www.overbuilt.com

The RM Johnson Co.David Van Vleet 800-328-3613 www.ezcrusher.com

Sierra International Jose Pereyra 800-343-8503 www.sierraintl.com

Although a Reuters report notes that the average age of a vehicle in the United States hit a record in 2020 of 12.1 years, the U.S. still junks approximately 12 to 15 million cars annually. They are the most plentiful recycled consumer item in the world, which results in over 14 million tons of recovered steel. For those in the industry who are in the business of that recovery work, there are a number of machines available to help.

The Imabe CH-5000-HD baler for vehicles and scrap in general, “is carefully designed and meticulously constructed, and has passed ISO 9001 quality requirements and limit performance tests prior to sale. This practice ensures that our products include sound technology and proven performance,” explained Cesar Benitez, chief operating officer.

The CH-5000-HD model’s main body houses the chamber or feeding and precompacting area. The level of over-sizing of baler components is 1:3. Moving parts of the machine include precompression side caps and compaction rams. Feeding and compression tasks are performed simultaneously but independently. The chamber that encloses these functions is a base of two longitudinal side walls articulated by robust hinges and two hydraulic cylinders at each side. Two mobile rams inside the machine compress vehicles longitudinally. All baler elements in contact with material processed are protected by Hardox 45 wear plates, which allow the machine structure to remain intact. As the machine rams advance, material volume is compacted after already being reduced by the side lids of the machine. This process of forward and backward movement is powered by hydraulic cylinders. The pusher rams are also lined on all external faces with Hardox wear plates to avoid wear due to contact with the material being baled. This static model is super-reinforced and so can process packing material (such as corrugated steel bars) with a hardness of 56kg. This allows the machine side cylinders to be protected throughout operation so that rod components are never damaged. The entire machine cycle is very rapid because movement is reduced in both the advance and retreat functions.

According to John Kitchens, president of Iron Ax, “We offer a 20’ and a 16’ baler. Our balers feature a Cummins engine, and the baler we currently manufacture features an automatic cycle and remote control. The latter is rechargeable, and it has a longer range than previous models offered.”

Kitchens also mentioned how the baler system allows the remote control to communicate with the engine via a CAN network. The future evolution of this control system will feature optional systems such as remote diagnostics and GPS tracking. On board diagnostics via a control panel display will also be offered, which in turn will make setting hydraulic pressure easier than ever before. The ability to adjust the pressure allows an operator to make either a loose or a tight bale with the Iron Pack Baler.

“We know what processors are looking for when it comes to a baler. We have roots in scrap metal recycling, and we use the products in our scrap operation every day. Our customer service sets us apart from other manufacturers. Many of our service employees have been with us over 25 years. They not only know the machines, they get to know customers and the operators, too. We are available on the weekends as well. We realize that issues sometimes appear at an inconvenient time, so we’re available almost 24/7 to help our customers resume their operations.

“Our Iron Pack Baler is a high-speed product. Average baling time is approximately one minute and our customers see an increase in tons processed after adding this machine to their operation. Setup time is minimal with all of our balers. Upon arrival at the jobsite, you will be ready to operate in just minutes,” Kitchens added.

He noted that baler sales continue to increase as yard owners realize the need for them, and how “with a car crusher you are limited to crushing cars. With a baler you can process cars, white goods, loose iron and more. A baler is a versatile machine that can help process various streams of scrap. A lot of customers have discovered how they can purchase more and/or different types of material than they could prior to running a baler, which allows them to process the materials with ease.”

The RM Johnson portable E-Z Log Baler produces a bale in a fast, neat process. “It is ready to operate, after a fluid level check and a user can move the grapple crane up to 400°, reach out 23’ and lift 2,000 lbs. By selecting the metal type and volume of each bundle, a user can produce log bales to fit the requirement of the desired market and the E-Z Log Baler can operate from the control platform. The unit can be moved to the same location as the scrap that must be processed. We offer three other logger models as well,” stated Dave Van Vleet, sales manager. He continued, “Even expensive machines are worthless if the final product can’t be shredded. Our innovative hydraulic compression sequence solves this problem. Once loose scrap is loaded onto the baling chamber, the E-Z Log, as opposed to mere compressing, produces a log that will stay together even when dropped. Yet the rolled logs remain loose and low density enough for a 1,500 h.p. shredder to easily process them.”

\Van Vleet touted the simple but unique design of the machine, with easily accessible components, which aids trouble-free operation and servicing. “Fewer moving parts and smaller hydraulic cylinders produce a better bundle at a lower processing cost than other loggers. All of the hydraulic cylinders are manufactured with high-grade, seamless, polished steel at our factory. All E-Z Log Balers also use standard parts and components. Operating instructions are provided by our trained specialists and baler options include stationary or portable; diesel, gas or electric engines. Custom designs and specifications are also available,” he said.

Published in the March 2023 Edition of American Recycler News

For years, tire derived rubber has been used to manufacture numerous recycled rubber products. By mechanically shredding tires and then magnetically separating the steel...

Add Your Organization The Breast Cancer Research Foundation Donate Your Vehicle to BCRF and Make a Difference! Help defeat breast cancer with your tax...

by MAURA KELLER mkeller@americanrecycler.com The cost of tipping fees within the waste and recycling industry is steadily increasing, according to the Environmental Research &...

Car tires are round, black and made of rubber. Look closer, however, and you’ll see that the design of tires and the interaction of...

Used Clothes Twin Chamber Baler Privacy Policy | Terms of Use 877-777-0043 • Phone 419-931-0737 • Fax 419-931-0740 • 1789 Indian Wood Circle #250, Maumee, OH 43537 © Copyright American Recycler News, Inc. All rights reserved. Any reproduction of content requires written permission.