As a contract crusher, Fred Weber tackles jobs anywhere in the continental U.S.

To deliver quality products at the lowest cost per ton, the Missouri-based company combines the best human resources with custom processing solutions. Because every project is different, each plant in its portable fleet is customized and configured to fit the specific job. Vertical Impact Crusher

Currently, one of the new portable spreads is crushing granite on an estimated three-year-long contract near Loveland, Colorado, where Fred Weber’s dedicated crew supplies construction materials for a major reservoir project.

Fred Weber’s Steve Valle, a 25-year industry veteran who’s the general superintendent on the site, says portability is in his DNA, as he’s “never in one place for too long.” Whether bouncing from quarry to quarry or serving on longer crushing jobs like the one in Colorado, Valle recognizes that portability is what Fred Weber does.

“Having a complete spread like this one, customized entirely to our needs, makes our operation more safe, productive and efficient,” he says.

When researching new plants for the Colorado project, Valle says Fred Weber selected Superior Industries as a partner because the company designs and manufactures every plant component – from feeding and screening to crushing and conveying, plus all of the electrical and automation.

“With most plants, certain components are outsourced to different manufacturers,” Valley says. “If there’s a problem, you’re often referred to another party, and there’s a lot of finger-pointing. With Superior, there’s only one source to go to – and they always have the solution for us.”

Valle also points to the advantage of having Power Equipment Co., a Superior dealer, nearby. Not only does Power Equipment supply parts and service support, but Valle says the local dealer was instrumental during the site prep phase, providing much of the grading and excavation equipment needed to construct roads and pads ahead of the plant’s arrival.

When coming into a bare site and setting up a new plant, Valle says there are always issues to work through.

“Whether on the phone or in person, Superior is always there to troubleshoot,” he says. “They were on-site with us from setup to start-up and throughout the training process.”

To achieve maximum efficiency, Valle says each chassis and each crushing and screening component on the plant is customized to meet desired feed gradations, product specifications, throughput, production capacity, material transfer and stockpiling volume.

First, the control house is mounted on a hydraulic raise and lower system to allow the operator to look over the primary jaw. Because the control house is outfitted with a rock breaker, the operator can more efficiently reduce shot rock and other oversize material.

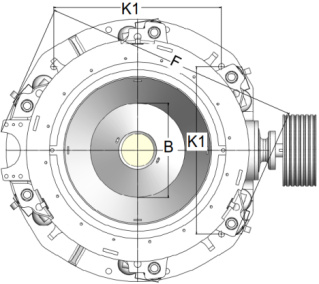

Superior also “dialed in” an ability to automate and control crusher feed. The cone and vertical shaft impact crushers are equipped with feed bins while belt feeders have variable-frequency drives. Via an automation program, the feed is controlled to ensure the cone crusher is choke fed, as the belt feeder automatically speeds up or slows down depending on amp draw, as well as the fullness of the crusher cavity.

As for product flexibility, each screen is equipped with chutes and flip gates.

“In just minutes, with the flip of a gate, we can alternate between blending several products or process three separate products, for example,” Valle says. “It’s just that simple.”

Additionally, because Superior manufactures all plant components, Valle says more opportunities for customization are available.

“While this new spread is customized to suit the current project, we can easily separate out components or reconfigure the plant for future jobs,” he says. “Due to its design and engineering, this plant gives us product flexibility today and will continue to deliver that versatility when we move on to the next project.”

« Prev Page 1 2 Next Page »

If you enjoyed this article, subscribe to Pit & Quarry to receive more articles just like it.

Metso superior MKIII 60-89 © 2024 North Coast Media LLC, All Rights Reserved.