Dear user, ET CIO privacy and cookie policy has been updated to align with the new data regulations in European Union. Please review and accept these changes below to continue using the website. You can see our privacy policy & our cookie policy. We use cookies to ensure the best experience for you on our website. If you choose to ignore this message, we'll assume that you are happy to receive all cookies on ET CIO.

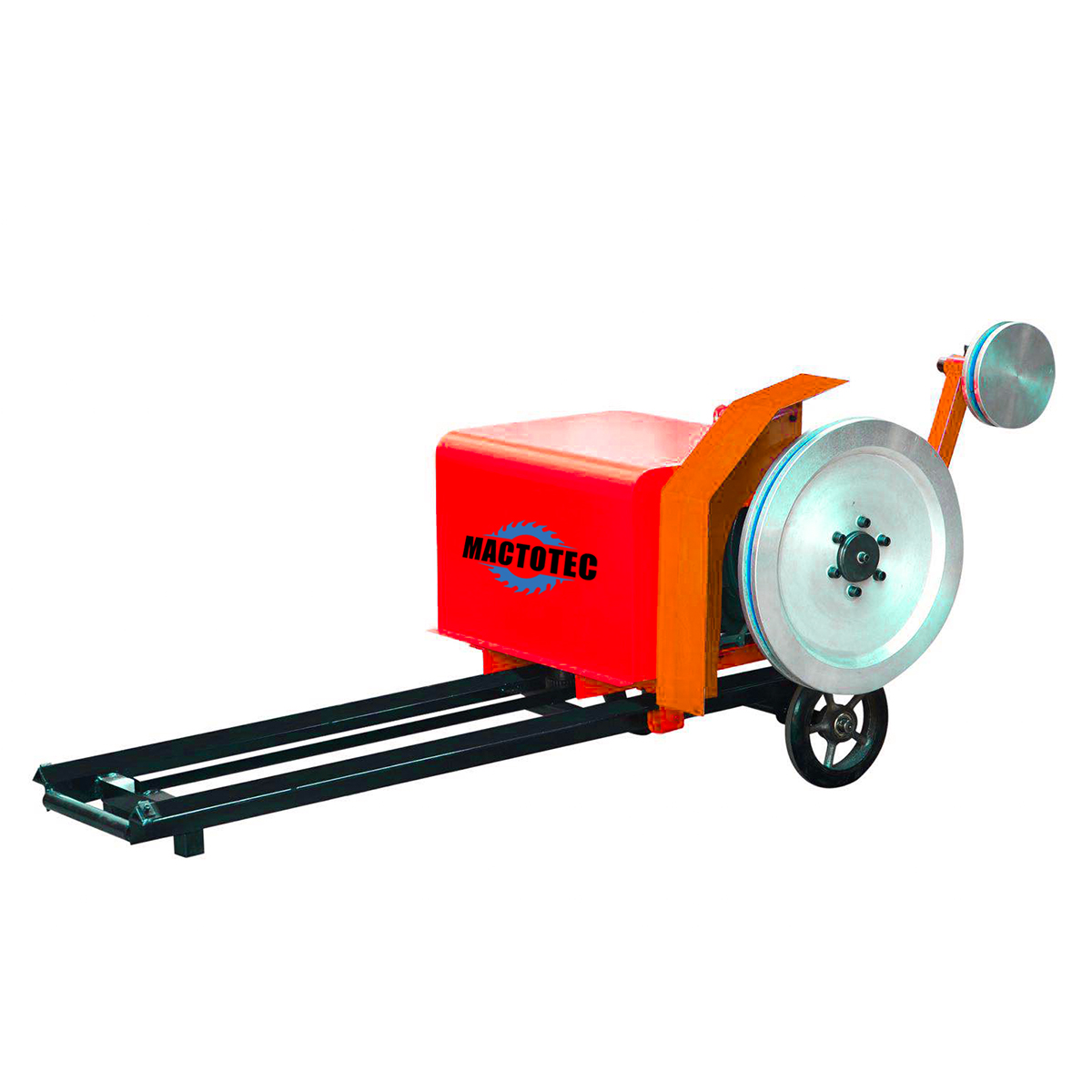

SVB collapse is a failure of risk assessment and BCP17 hrs ago Limestone Calibration Machine

Bringing digital India dream to life through data: Rajesh Sinha, Fulcrum Digital1 day ago

This hub, brought to you by Zoom and ETCIO, brings..

Building Trust In A Digital World

Data scientists and data analysts have overlapping duties but function differently in terms of the data they work with. While data analysts primarily work with structured data to create dashboards, reports and monitor metrics, data scientists collect, organise, and process massive amounts of structured and unstructured data to build predictive or prescriptive models using advanced technologies like Machine Learning and Deep Learning. Both professions offer excellent career growth opportunities, and data analysts can transition to become data scientists by learning new skills like programming languages and machine learning.

Join the community of 2M+ industry professionals

ChatGPT can be both a blessing and a curse in the realm of cybersecurity, say infosec experts

More organizations' data waiting to be leaked? Here is the inside story as an ETCIO exclusive on the recent data breach at a subsidiary of HDFC Bank

We have various options to advertise with us including Events, Advertorials, Banners, Mailers, Webinars etc.

Please contact us to know more details.

Get ETCIO 's top stories every morning in your email inbox.

Join the community of 2M+ industry professionals

Stone Cnc Machines Follow @ETCIO for the latest news, insider access to events and more.