Many products featured on this site were editorially chosen. Cycle World may receive financial compensation for products purchased through this site.

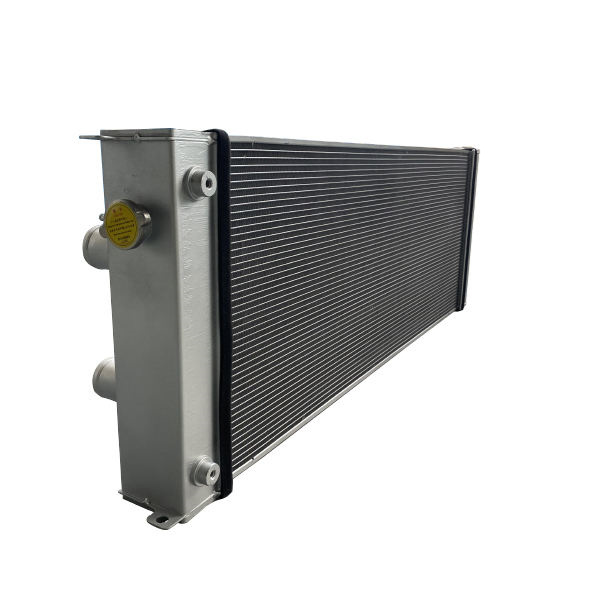

Copyright © 2023 Cycle World. An Octane Media, LLC Publication. All rights reserved. Reproduction in whole or in part without permission is prohibited. Komatsu Off Road Oil Cooler