For full functionality of this site it is necessary to enable JavaScript. Here are the instructions how to enable JavaScript in your web browser.

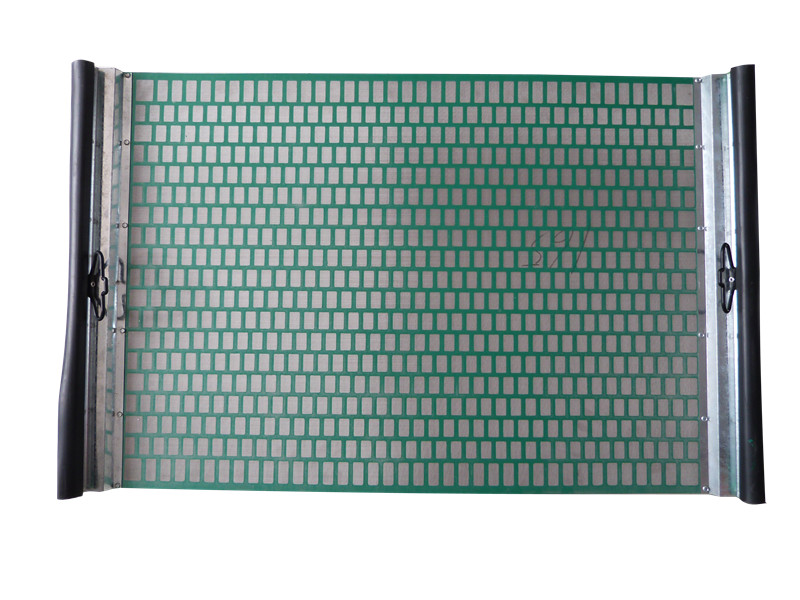

Save to read list Oilfield Technology, Tuesday, 12 May 2015 10:00 NOV Brandt VSM Multi-sizer Primary Screen

M-I SWACO, a Schlumberger company, recently announced the release of the SCREEN PULSE fluid and cuttings separator. Easily installed onto new or existing shale shakers, the fully pneumatic system delivers drilling fluid recovery of up to 30 bpd and an average drill cuttings waste reduction of 20%.

“Whether drilling on land, in shallow waters or in deepwater, our customers are always seeking ways to optimise the efficiency of their solids control process and thereby lower their total cost of drilling,” said Guy Arrington, President, M-I SWACO. “Combined with our shaker technology and lightweight composite screens, the new SCREEN PULSE separator maximizes drilling fluid recovery and generates drier cuttings. This reduces waste handling and disposal and overall drilling costs.”

The SCREEN PULSE separator is a retrofitted, fully pneumatic system equipped to operate up to four shakers simultaneously. A carbon fibre pan fitted with an air valve mechanism that provides a pulsing air supply pulls drilling fluid from the cuttings surface as they travel towards the discharge end of the shaker.

The new separator was field tested in the Middle East, South America, and North America, including Oklahoma, Pennsylvania, Texas and Louisiana, proving a significant reduction in waste and increase in drilling fluid recovery in all basins.

In the Eagle Ford shale in South Texas, a customer wanted to maintain optimal drilling conditions, including high rate of penetration, while minimising costs associated with synthetic-based mud (SBM) loss and the disposal of wet cuttings. The SCREEN PULSE separator was installed on MONGOOSE PRO shale shakers and used in combination with DURAFLO composite screens to enhance fluid handling capacity and solids control performance. Using this solution on two wells, the customer achieved the drilling objectives and reduced the SBM cost per foot by 30% and the disposal cost per well by 13.5%.

Adapted from press release by Cecilia Rehn

Perenco UK has announced a decommissioning milestone with the successful completion of the plug & abandonment of three subsea wells at the Gawain field in the UK Southern North Sea, including the removal of the associated subsea infrastructure.

GEA Mechanical Equipment recently delivered the first retrofit plant to a drilling platform offshore Alaska.

Solution won the CIPPE Innovation Gold Award by showcasing green thinking for oil and gas development in a safe and eco-friendly way.

NeoTork automatically manages torque generated from the drill bit and mitigates axial and torsional vibrations.

Scientists have developed new geochemical tracers that can identify fracking flowback fluids that have been released into the environment.

Embed article link: (copy the HTML code below):

This article has been tagged under the following:

This content is available to registered readers of our magazine only. Please sign in or register for free.

Register for free » Get started now for absolutely FREE, no credit card required.

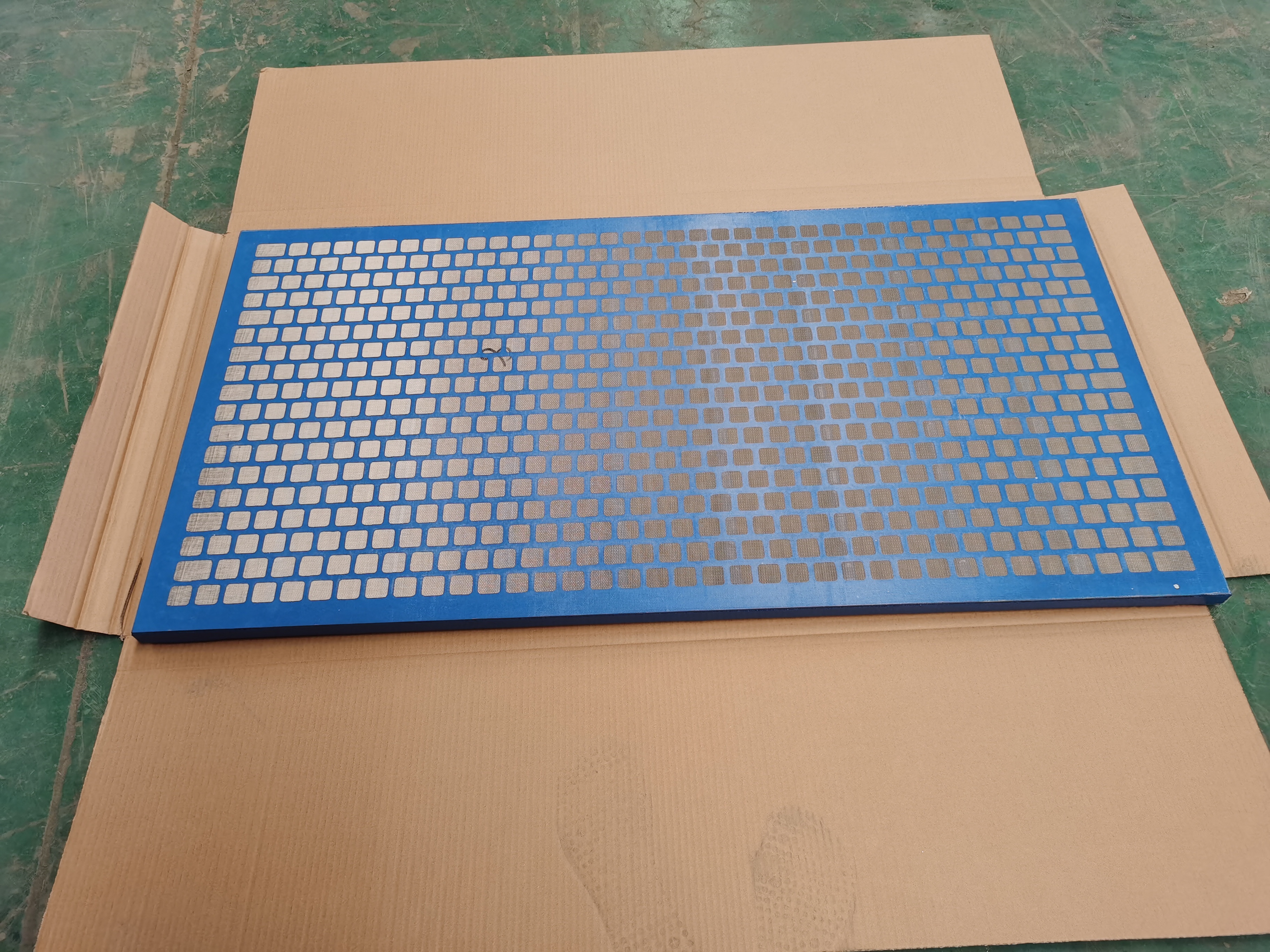

Mud Shaker Screen Copyright © 2024 Palladian Publications Ltd. All rights reserved | Tel: +44 (0)1252 718 999 | Email: enquiries@oilfieldtechnology.com