Subscribe to our Daily Headlines newsletter.

Video provided in partnership with The Times, JEDtv and WJOB. Sponsored by Strack & Van Til. Cnc Milling Shop

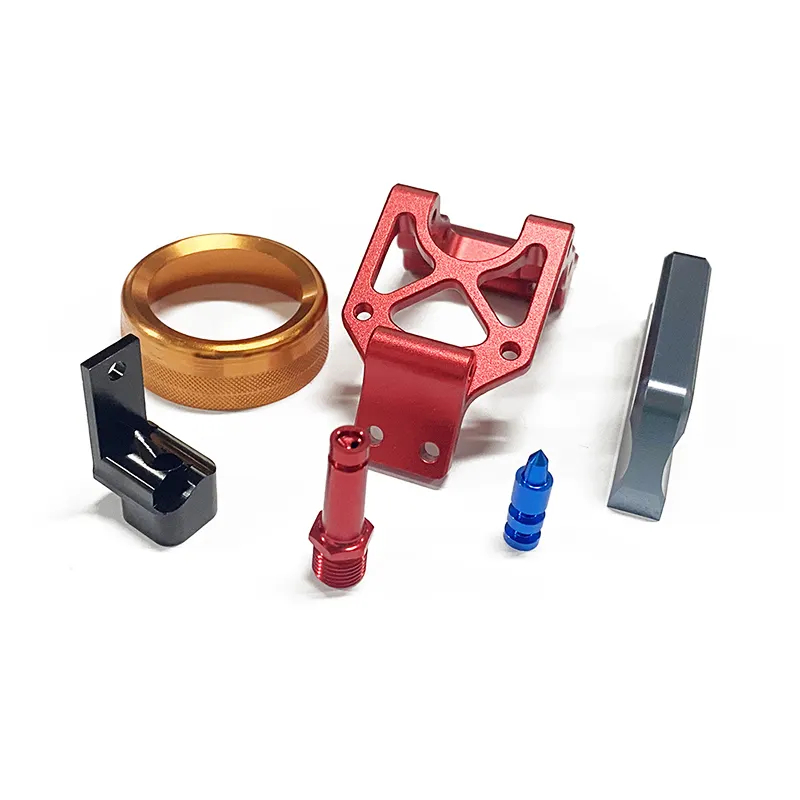

A new precision machine shop has set up shop in the Knox Industrial Park.

Wakal Machining opened at 205 Kloeckner Drive in Knox. The city and the Starke County Economic Development Foundation recently held a ribbon-cutting ceremony for the company, which cuts, fabricates and finishes various products.

It repairs equipment and makes new parts for regional customers, including in the manufacturing, aerospace, automotive, farming and construction sectors.

“Our client base is farmers and any business that has a maintenance department,” owner Bill Wakal said. “We hope to be able to serve Valparaiso, LaPorte, Walkerton, Plymouth, Culver, Winamac and surrounding areas initially, and branch out further into northern Indiana and beyond as we grow. The nearest machining shop that can provide the service we will offer is an hour and a half away.”

Wakal has worked as a tool and die maker for the past 25 years. He founded the company with his wife Sherry. The company is starting out with two employees but plans to hire more in the future.

“We chose to start our business in Knox because we saw a need for a machine shop in Starke County. The Knox Industrial Park is an ideal location because of the proximity to many of our clients, which will help us to better serve their needs," Wakal said. “We hope this opens the door for other small businesses to consider locating in Starke County. The City of Knox and the Starke County Economic Development Foundation have been a positive force behind the success of us starting this business.”

In 2022, the company approached the Starke County Economic Development Foundation about sites where they could locate.

“We looked at many possibilities in the Knox area, which is where they wanted to locate,” SCEDF Executive Director Lisa Dan said. “They felt the Knox Industrial Park was the best location, and we were happy to sell them some land so they could build. They indicated some of their customers would be local industries and this would be an ideal spot for their startup business.”

Wakal Machining plans to hire through the precision machine program at Ivy Tech and the vocational program the North Central Careers and Technical Education Cooperative offers at local schools.

“Their long-term plans will also create career opportunities for local students and encourage them to remain in Starke County after they graduate,” Dan said. “That is so important to our county as we continue to strengthen our niche as a best-of-both worlds destination in proximity to Chicago, South Bend and Indianapolis with an affordable cost of living, unmatched natural resources, and friendly and welcoming communities.”

Wakal Machining is open from 11 a.m. to 6 p.m. Monday through Friday.

Subscribe to our Daily Headlines newsletter.

Email notifications are only sent once a day, and only if there are new matching items.

Video provided in partnership with The Times, JEDtv and WJOB. Sponsored by Strack & Van Til.

Precision Cnc Machined Components Get up-to-the-minute news sent straight to your device.