Sponsored content by Lane Persky, Marketing Manager: Communications and Channel, Marketing

What are Spirolox retaining rings used for? Retaining rings serve as a removable shoulder within an assembly to literally retain components in a bore or on a shaft. Flat Nose Snap Ring Pliers

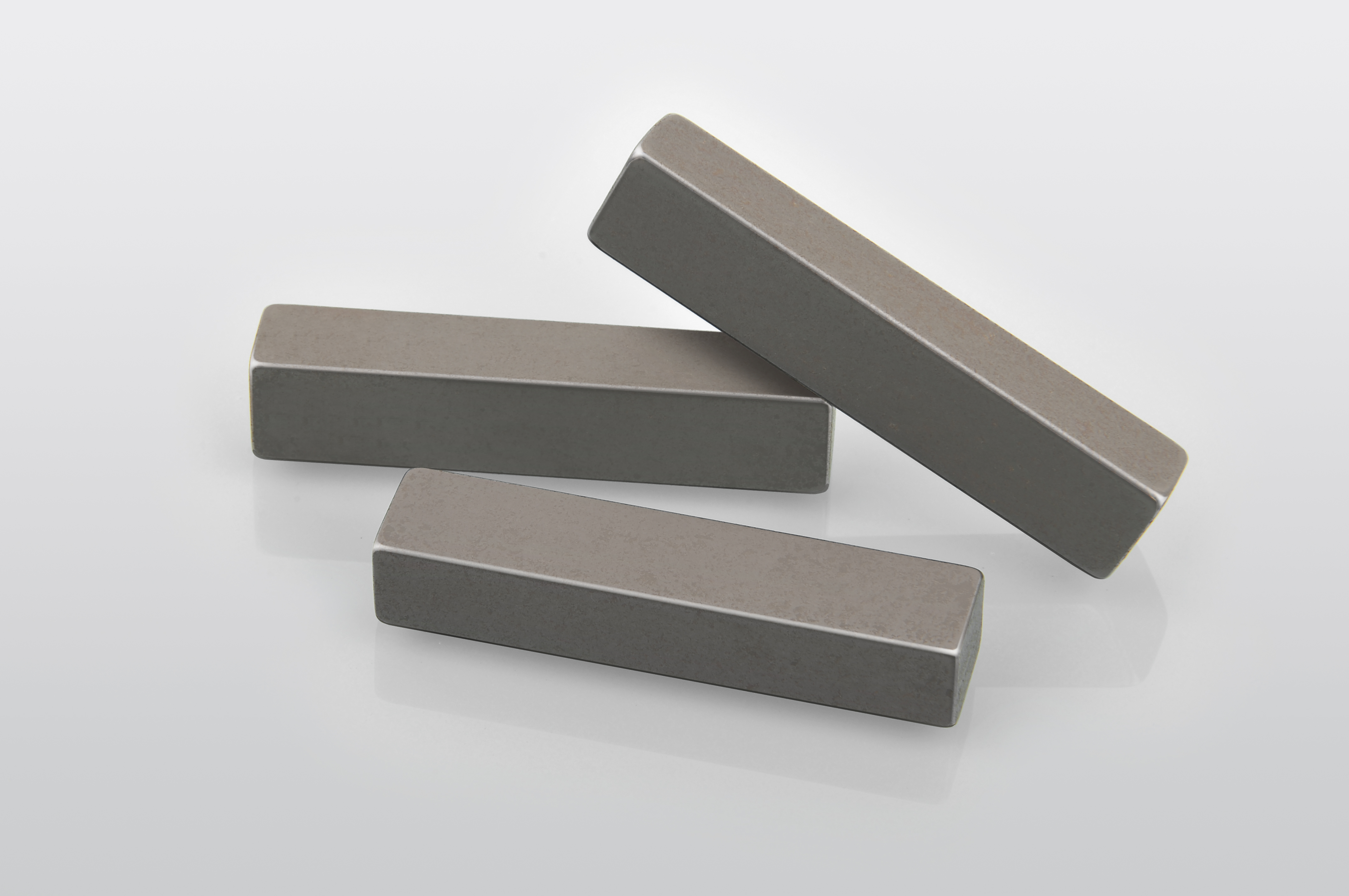

How are these retaining rings made? Spirolox® retaining rings from Smalley are specifically coiled on edge from rectangular cross-section flat wire as opposed to rings that are stamped from a sheet. Common materials used are carbon steel and 302 stainless steel. These rings consist of one or more turns depending on the force and strength needed within an application. The rings can be edge-wound to nearly any custom diameter—a huge advantage over die-stamped components that require tooling. Multiple turn rings eliminate the gap, providing a full 360 degrees of contact.

Are these retaining rings difficult to install? Not at all. The rings can be inserted by hand and easily wound into a groove. The easiest method of installation is to separate the multiple coils and insert an end into the groove. Then press down around the circumference and wind the ring into place.

Can this be done using an automated process as well? Semi-automated and automated installation is possible. For example, in an internal grooved application, a plunger and tapered housing sleeve (suggested taper of 6 degrees) are used. The sleeve acts as a guide, while the plunger pushes the retaining ring into position.

For external applications, a plunger and tapered plug are used for installation. First, the plug is centered over the shaft end (again at a suggested taper of 6 degrees). The plunger fits loosely and pushes the ring into position over the plug. The same sleeve or cone with a plunger concept can be applied for fully automated assembly as well.

We’ve talked a lot about installation, but how easy are the retaining rings to remove? Spirolox retaining rings feature removal notches for extraction from within a groove. No special tools are required. The notch creates a gap between the end of the ring and the shaft or housing, which allows an object, like a screwdriver, to be inserted into that gap to pry the ring free. Once the first end of the ring is pried out of the groove, grab the ring and spiral it out just as easily as it went in. For removal where clearances are very tight, consult a Smalley Engineer for the best option for your specific situation.

Is there anything else to consider when installing or removing a Spirolox retaining ring? One of the biggest advantages of using a Spirolox ring is that they can be safer to install and remove than a standard stamped circlip. This is especially true in larger diameter applications where high forces are applied to the ring pliers to contract or expand the ring for installation/removal. The controlled, spiraling of a Spirolox ring into the groove eliminates the risk of the ring flying off of the pliers.

Any other advantages? While the simplicity of installation and removal are clear advantages, Spirolox rings have many other benefits. Spirolox rings have no ears or lugs to interfere with assembly components and as they are coiled and not stamped. A cost savings can be realized due to the elimination of scrap. This makes stainless steel and other exotic alloys economically viable.

Retaining rings can be made from a variety of different materials, some of these include Inconel X-750, a nickel-chromium alloy for use in high temperature and corrosive environments; A286 Alloy, a precipitation hardened alloy; Elgiloy®, a material used in oil and gas industry applications for its resistance to sulfide stress cracking; Beryllium Copper Alloy #25, that combines low elasticity with high tensile strength; and Phosphor Bronze, a copper alloy that features high electrical conductivity.

If I have a unique application, can I get a custom made retaining ring? For all types of unique applications, retaining rings can be engineered to accommodate your needs. Smalley’s unique edge-winding process allows for the ring to be customized with No-Tooling-Charges™. The material, material thickness, radial wall, and end type of the ring can all be customized to your application requirements. Whichever ring configuration you decide to use, you will be getting the performance you need with the convenience of simpler installation and removal. All of which will save time and money during assembly and maintenance.

Browse the most current issue of Design World and back issues in an easy to use high quality format. Clip, share and download with the leading design engineering magazine today.

Top global problem solving EE forum covering Microcontrollers, DSP, Networking, Analog and Digital Design, RF, Power Electronics, PCB Routing and much more

The Engineering Exchange is a global educational networking community for engineers. Connect, share, and learn today »

Wide Snap Ring Pliers Copyright © 2024 WTWH Media LLC. All Rights Reserved. The material on this site may not be reproduced, distributed, transmitted, cached or otherwise used, except with the prior written permission of WTWH Media Privacy Policy | Advertising | About Us