Explore the world of composites through JEC Group’s multi-channel knowledge-sharing resources: JEC Composites Magazine & e-newsletters, in-depth analysis & market reports, technical & business conferences, video & social media platforms

Connect with the global composites community with JEC Group’s portfolio of international events & networking solutions, on and off-line: the world’s premier composites exhibition JEC World, specialist region & market-focused Forums & Summits, & one-to-one Business Meetings program Custom Cnc Machining Parts

Discover the composites technologies, people and organisations shaping the future through JEC Group’s showcases of creativity & collaboration: the renowned JEC Composites Innovation Awards, Startup Booster challenge, & industry-themed Innovation Planets.

Explore the world of composites through JEC Group’s multi-channel knowledge-sharing resources: JEC Composites Magazine & e-newsletters, in-depth analysis & market reports, technical & business conferences, video & social media platforms

Connect with the global composites community with JEC Group’s portfolio of international events & networking solutions, on and off-line: the world’s premier composites exhibition JEC World, specialist region & market-focused Forums & Summits, & one-to-one Business Meetings program

Discover the composites technologies, people and organisations shaping the future through JEC Group’s showcases of creativity & collaboration: the renowned JEC Composites Innovation Awards, Startup Booster challenge, & industry-themed Innovation Planets.

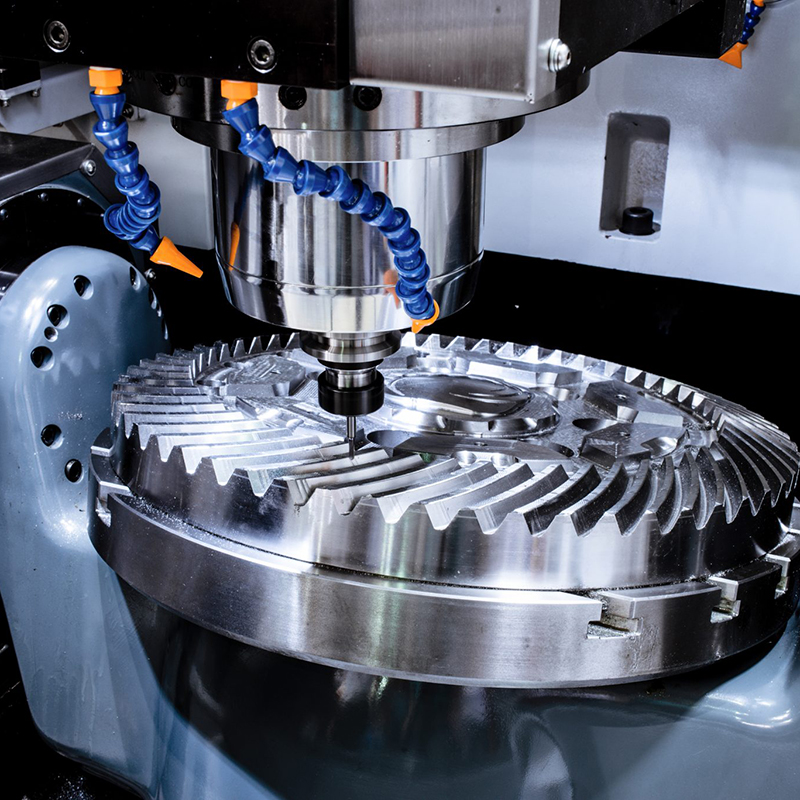

Refitech Composite Solutions has made a major innovation leap by installing a new 5-axis CNC machine for the finishing of composite components. This is in addition to the 3-axis machining centres the company already has in operation. The new machine will allow the machining of even more complex 3D shapes to be carried out fully automatically, with high speed, high quality and reproducibility in view of series volumes.

Refitech Composite Solutions has made a major innovation leap by installing a new 5-axis CNC machine for the finishing of composite components. This is in addition to the 3-axis machining centres the company already has in operation. The new machine will allow the machining of even more complex 3D shapes to be carried out fully automatically, with high speed, high quality and reproducibility in view of series volumes.

“With this new 5-axis machine, we can perform further post-processing on almost all the composite components we make,” says Marcel Gillis, CEO of Refitech. “That was a long-held wish of us and our customers, and with the new machine we reduce the number of manual finishing operations and guarantee even higher quality. This not only allows us to further increase efficiency and finish quality, it also means we can effectively manufacture even more components for our customers annually. Some manual finishing of composites will remain for the time being, but the intention is to optimise this even further in the coming years.”

“A machine like this is quite an investment, so we oriented ourselves well beforehand,” Marcel Gillis continues. “CMS from Zogno, near Bergamo, Italy, is a well-known name in the field of milling composites. Their offer looked promising and after visiting the factory in Italy and milling a test product, we were won over.”

The CMS’ 5-axis milling machine is specifically designed for machining composite materials. Thanks to ‘CMS Adaptive Technology’, a feature integrated into the controls, the operator gets the maximum parameters for material removal on a specific surface by simply calling up the relevant mapping. This significantly reduces cycle times on complex surfaces, without compromising finish quality and precision. The machine is provided with an acoustic enclosure to control dust, chips and noise during machining, putting the working area and operator safety first. “Further, Klaassen Machines, CMS’ agent in the Netherlands, has been great in helping us install and train our staff on the new machine,” Marcel Gillis adds in conclusion.

About Refitech: Refitech specialises in the engineering and series production of industrial composite components. Founded in 1989, the company provides composite solutions for various markets, including Mechanical Engineering, UAV systems, Aerospace, Mobility and the Defence industry. Services include composite engineering, prototyping, series production and assembly of carbon components and composite sandwich panels including CNC milling and bonding. Besides customisation of these product-market combinations, we offer a unique range of standard carbon profiles, panels and couplings in various sizes with very wide application possibilities through www.carbonwebshop.com. In addition to its headquarters in Waalwijk, the Netherlands, Refitech has its own production facility in Ningbo, China.

You can create a free technological watch and keep you updated about all these subjects.

Stay up to date with the latest composites news directly in your inbox. Subscribe for free to the JEC Composites International and French e-Letters.

Custom Cnc Machining Copyright © 1996-2024 JEC. All rights reserved.