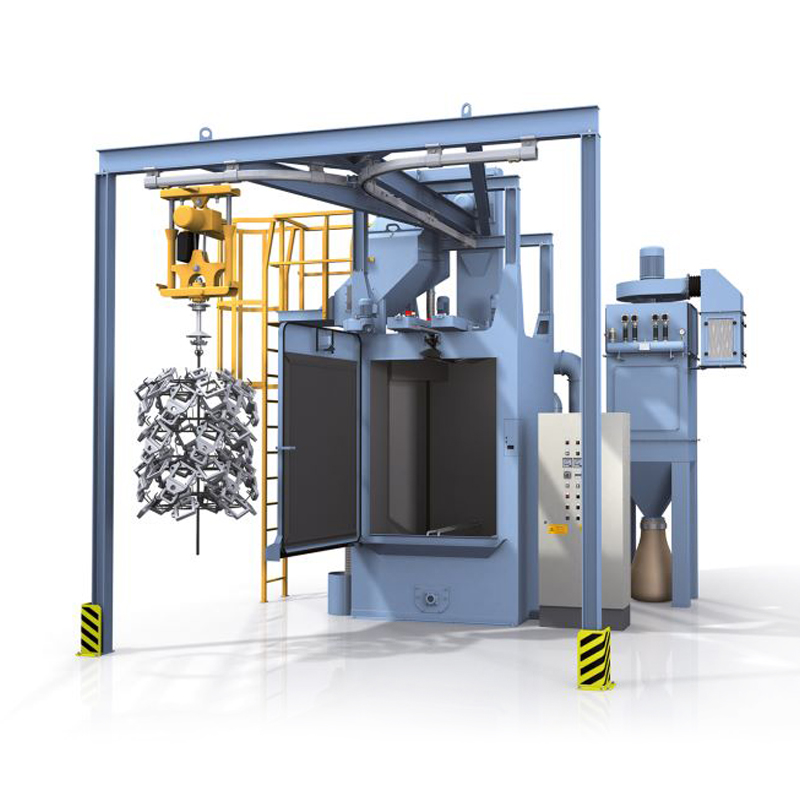

The MT422 shot blast machine from Viking Corp. features two indexed tables—one loads parts while the other rotates into the blast chamber—to help ensure a continuous workflow. It is designed for cleaning small components less than 6 in. tall.

The machine offers a 24- by 6-in. blast zone. Its 15-in.-dia., center-fed VMAX 1500 blast wheel runs at 3,600 RPM and 15 HP. The unit is lined with +1-in.-thick perimeter cast chrome-moly wear plates. There is no bushing, allowing mounting directly to the shaft. Structural Shot Blasting Machine

Safety light curtains stop the machine if an operator breaks the light curtains’ plane during operation. Options include rotary scalping drums, auxiliary abrasive hoppers, and peening packages.

The Fabricator is North America's leading magazine for the metal forming and fabricating industry. The magazine delivers the news, technical articles, and case histories that enable fabricators to do their jobs more efficiently. The Fabricator has served the industry since 1970.

Easily access valuable industry resources now with full access to the digital edition of The Fabricator.

Easily access valuable industry resources now with full access to the digital edition of The Welder.

Easily access valuable industry resources now with full access to the digital edition of The Tube and Pipe Journal.

Easily access valuable industry resources now with full access to the digital edition of The Fabricator en Español.

Jeff Cupples, the president of Jackson, Tenn.-based Cupples J&J Company, discusses his experience with laser cutting machines and...

© 2024 FMA Communications, Inc. All rights reserved.

Shot Blasting Pdf Not yet registered? Sign up