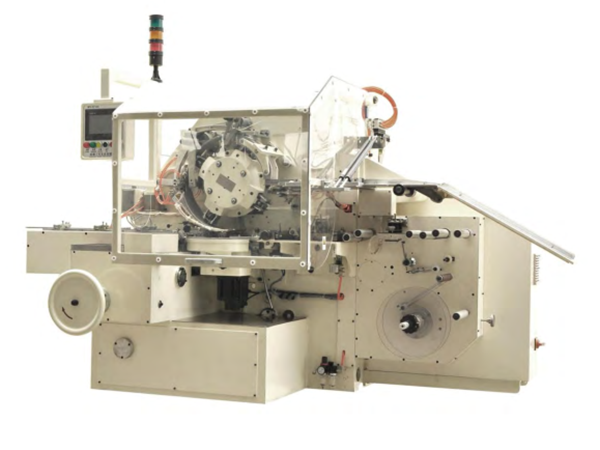

ÉLITER Packaging Machinery has unveiled Gran Sonata, an end-load, hygienic stainless-steel cartoning machine utilizing servo technologies for large-size cartoning and medium-size case packing with the aim of improving reliability and flexibility.

Multi-axis servo drive technology has been implemented instead of complex mechanical drive systems – a move expected to benefit the structure, maintenance, and function of the machine. Customers can switch between various products and formats with recipe-based changeover in a bid to reduce downtime between production shifts. Bubble Gum Wrapper

“Servo technology is the frontier of packaging advancement,” explains general manager Zhiwei Bao. “With each mechanism of the machine controlled separately but synchronously by servo motors through sophisticated programming and control system, the new automatic cartoning machine provides improved flexibility, stability, and reliability.”

“With our crews coming from the interdisciplinary background and who have past experience at the industrial leading companies, we strive to develop our new models that match our ‘next-generation’ mindset and target the high-end market.”

The machine is open-profile and seeks to help companies streamline their packaging processes with the compact option of secondary and tertiary packaging automation. ÉLITER adds that it can be adapted to an extra-extended size coverage.

Bao continues: “Our client will be able to use the Gran Sonata Cartoning Machine either in a conventional way as a packaging machine for setting up cartons, loading products, and finishing sealings or as a tertiary packaging machine similar to a case packer that loads large corrugated boxes (cases) with relatively smaller cartons in multiple arrangements.”

To further minimize downtime, the machine provides options for remote access devices for after-sales support. Its hygienic, stainless-steel execution facilitates further customization as a washdown to IP65, which offers ‘robust and hygienic’ cartoning automation options.

Gran Sonata is being displayed at Interpack Alliance Exhibition – Shanghai World of Packaging 2023. It is expected to apply to a range of industries, including food and pharmaceuticals, at a low cost.

In other news, Romaco Noack revealed its Unity 600 blister packaging line earlier this year. It is said to offer a maximum output of 600 blisters and 350 cartons per minute and seeks to improve efficiency and lower emissions in pharmaceutical and nutraceutical packaging.

More recently, Emmeci’s E-BM fit-to-size box-making machine was unveiled for the e-commerce sector, while Proseal’s CP4 case packer aspires to pack up to 240 trays per minute in certain applications.

If you liked this article, you might also enjoy:

The L’Oréal approach to packaging sustainability

The way we talk about plastic needs to change – here’s how to get it right

What steps is Apple taking to make its packaging more sustainable?

The Danone approach to packaging sustainability

Sponsored by ATS-Tanner Banding Systems AG

Lollipop Double Twist Wrapper Site powered by Webvision Cloud