C&L Aviation Group has completed c onstruction of its 12,000-sq-ft aircraft interior refurbishment facility. It is one of five building projects that have been completed for the company since the onset of the Covid-19 pandemic in 2020.

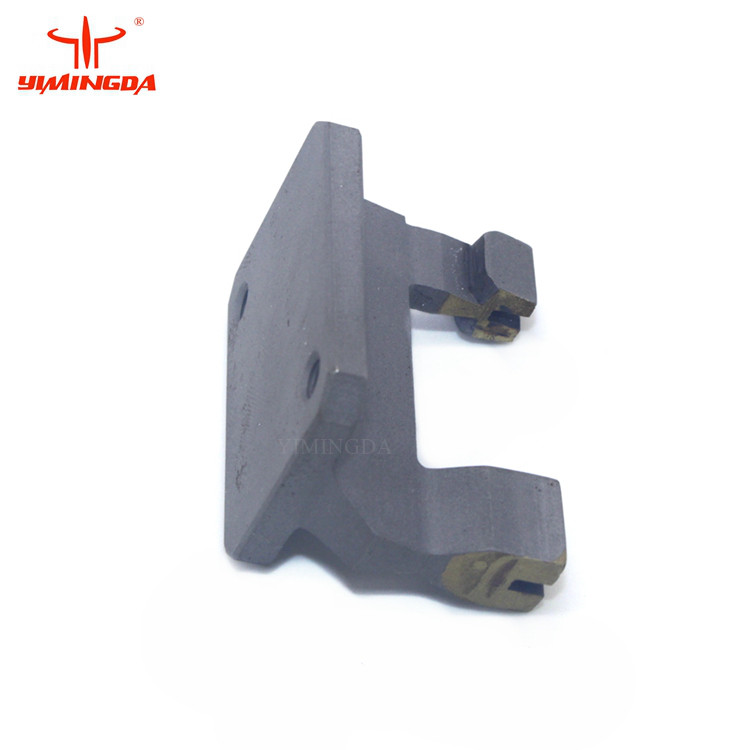

The newest facility for the Bangor, Maine-based MRO provider will address the increasing demand C&L has been seeing for regional and corporate aircraft interior refurbishment projects. Its new building features a Gerber leather cutting machine, laser engraving machines, paint booth, seatbelt manufacturing center, and assembly and disassembly areas. Republic Blowers

“We’ve made substantial investments in space, equipment, and manpower for the aircraft operators we serve,” said C&L CEO Chris Kilgour. “The new facility, along with increased in-house capabilities, provide us with robust options for customers looking for anything from a basic replacement of soft goods to complete interior upgrades and modifications.”

C&L’s four previous building projects include the purchase of an events center near Bangor airport for conversion to an aircraft component shop, construction of a 27,000-sq-ft aircraft parts warehouse, a 5,000-sq-ft addition to an existing hangar for storage, and a complete renovation of the company’s corporate aircraft maintenance hangar.

https://www.ainonline.com/aviation-news/business-aviation/2022-06-16/cl-aviation-wraps-series-building-projects

Lectra Plotter Copyright ©2023 AIN Media Group, Inc. All Rights Reserved. | Terms of Use | Privacy Policy | Content Policy