A key step in Honda’s electrification strategy, the new fourth-generation of the Honda two-motor hybrid system maximizes efficiency without compromising a vehicle’s dynamic performance or packaging. Delivering a sportier driving experience and improved capability, this latest version of the hybrid system is available in the all-new 2023 Honda CR-V, and now Accord, which will represent about 50% of CR-V and Accord sales annually.

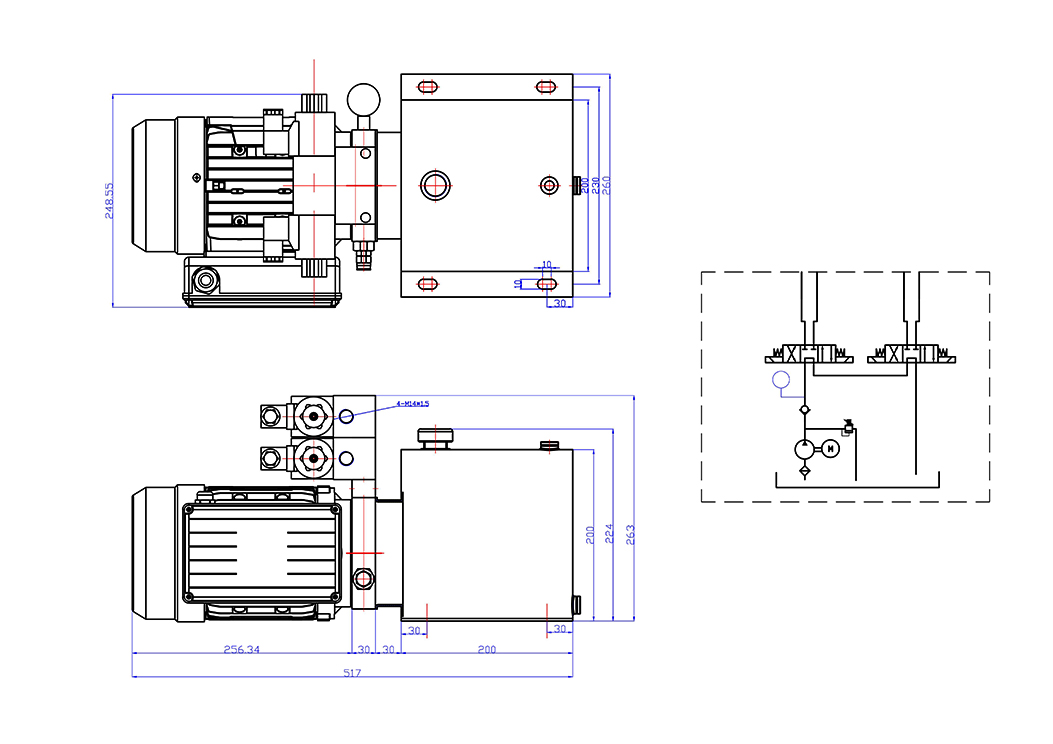

Debuting in the 2014 Accord Hybrid, the Honda two-motor hybrid system has become smaller, lighter, more powerful and more efficient with each generation. It consists of five core components: 12v Hydraulic Pack

See below for more information on these core components.

New Fourth-Generation: 2023 CR-V and Accord The first three generations of the Honda two-motor hybrid system used two electric motors mounted in-line with each other, with the generator motor connected directly to the engine, and the propulsion motor connected to the drive wheels.

The new fourth-generation of the system in the 2023 CR-V and Accord works differently. The two electric motors are now side-by-side, which has multiple benefits.

The IPU and PCU were further optimized for size and efficiency. The IPU houses a 1.06 kWh battery, along with the controlling hardware, in a 24% smaller package that weighs 12% less than its predecessor. This smaller size enables CR-V and Accord hybrid models to have the same cargo space as their non-hybrid counterparts. The PCU located under the hood now features a lower profile than before, creating more room in the engine compartment for better noise management.

The newest version of the two-motor hybrid system also features an all-new 2.0-liter 4-cylinder engine. With the addition of direct multistage fuel injection, the new Atkinson-cycle 2.0-liter DOHC i-VTEC® 4-cylinder increases power to 145 hp (SAE net at 6,100 rpm) and torque to 138 lb.-ft. (SAE net at 4,500 rpm) in CR-V, and 146 hp (SAE net at 6,100 rpm) and 134 lb.-ft. (SAE net at 4,500 rpm) in Accord. The changes also significantly reduce emissions, with nitrogen oxides (NOx) reduced by 22%, and total hydrocarbon (THC) emissions reduced by 24%.

For the first time on CR-V, the two-motor hybrid system is available with front-wheel drive or with Honda’s Real Time AWD with Intelligent Control System™. All Accords are front-wheel drive.

Drive Force Transfer Rather than use a torque converter or mechanical pulley or belt, the two-motor hybrid system relies on the interplay of the two motors for driving and generating power. This form of drive force transfer offers smooth and predictable acceleration matched with efficient low-rpm highway cruising when the gasoline engine is in operation.

Under most circumstances, the gasoline engine connected to the generator produces electricity, which is subsequently fed through the battery, and then to the drive motor. The system is able to optimally and rapidly control both engine and electric motor rotation in order to deliver higher fuel efficiency and quicker engine response in each driving mode.

In the 2023 CR-V Sport and Sport Touring, the new side-by-side arrangement of the electric motors in the new fourth-generation of the system enables an additional low-speed lockup clutch. This allows direct engine drive under a wider range of vehicle speeds.

When cruising at mid- or high-speeds in the high-efficiency range of the engine, a lock-up clutch engages the drive motor to the generator motor, transmitting engine torque directly to the drive wheels as efficiently as possible.

Propulsion and Generator Motors Honda’s two-motor hybrid system can operate as either a series or parallel hybrid. The majority of the time, the system operates as a series hybrid. Its electric propulsion motor drives the wheels directly, while the gasoline engine connected to the electric generator/starter motor functions as an electrical generator, supplying power to the hybrid battery and/or the propulsion motor. Under certain driving conditions, such as steady-state cruising at highway speeds, the system switches seamlessly to parallel hybrid operation, with the gasoline engine connecting to the front axle via a clutch, and vehicle speed is proportional to engine speed (rpm).

During braking or when coasting, the propulsion motor converts the kinetic energy of the decelerating vehicle into electrical energy to recharge the battery. The brake system seamlessly coordinates mechanical and regenerative braking with an electric-servo braking system for natural, linear, and responsive brake performance and pedal feel.

In addition to supplying electric energy to the propulsion motor, the generator motor can also be used to recharge the battery under certain conditions. The generator motor also restarts the gasoline engine when resuming travel after idle-stop has engaged.

Atkinson Cycle Engines The two-motor hybrid system features a 4-cylinder engine that uses the highly efficient Atkinson cycle. The Atkinson cycle holds the intake valve open longer than normal during the compression stroke, allowing a reverse flow of intake air into the intake manifold. This allows more complete use of the energy from the combustion process, greatly enhancing efficiency.

As a result, each engine paired with the two-motor hybrid system has been among the most thermally efficient gasoline engines ever used in a mass-production vehicle, with a thermal efficiency of around 40%, compared to the 25% to 30% thermal efficiency of most combustion engines.

In all versions of the system powering 2014-2022 Accord and 2020-2022 CR-V, a 2.0-liter DOHC i-VTEC® engine (LFA1) is used, while the smaller Honda Insight is equipped with a 1.5-liter DOHC i-VTEC® engine (LEB-MMD). Each gasoline engine uses a high compression ratio (13.0:1 to 13.5:1 for the 2.0-liter, 13.5:1 for the 1.5-liter), but thanks to advanced combustion chamber design, precise combustion control and anti-knocking technologies, each is able to operate using regular unleaded fuel.

Contributing to that efficiency and critical to the operation of the Atkinson cycle is a lightweight DOHC i-VTEC® cylinder head, with Variable Timing Control (VTC) on the intake cam used to continuously adjust the intake cam phase. i-VTEC® changes the lift profile, timing and duration of the intake valves’ operation. More information about the benefits of VTEC® is available here.

In all vehicles powered by the two-motor hybrid system, the gasoline engine can be decoupled from the rest of the hybrid powertrain and operate only as needed. Depending on the state of battery charge and other parameters, it will automatically shut off during deceleration and when the vehicle is at a stop or operating under battery power. When needed, the gasoline engine restarts automatically, without action from the driver.

Intelligent Power Unit The Intelligent Power Unit (IPU) houses the lithium-ion (Li-Ion) batteries. Compact and lightweight, the IPU allows for optimum placement of the batteries with minimum intrusion into the vehicle’s cargo or passenger space.

The IPU also manages the battery to maintain optimal charge states over a wide variety of operating conditions. The battery is recharged by the propulsion motor operating in regenerative braking mode, and by the generator motor, which is powered by the gasoline engine. The battery powers the electric propulsion motor.

Power Control Unit The “brain” of the two-motor hybrid system is the Power Control Unit (PCU). It controls all hybrid functions as it dictates the power management strategy to optimize performance. Based on driving conditions and power demand, it decides which drive mode is best and how much power from the generator should go to recharge the battery or drive the vehicle’s propulsion motor.

Drive Modes Three different operating modes are used by the two-motor system, which seamlessly switches between the three depending on throttle position, state of battery charge, and other factors.

EV Drive Mode – Active when starting from a stop, during light cruising and acceleration, and when braking. The gasoline engine is off in this mode and is decoupled from the drivetrain to reduce friction.

Hybrid Drive Mode– The electric propulsion motor alone powers the front wheels, with the gasoline engine powering the electric generator motor, which in turn provides power to the battery pack. This either supplements the battery by providing added electrical power to the propulsion motor or charges the battery if needed.

Engine Drive Mode – Under certain conditions, such as when cruising at medium to high speeds, the high-efficiency Atkinson-cycle i-VTEC® gasoline engine provides propulsion via a lock-up clutch that connects the generator motor to the propulsion motor. This effectively sends power directly from the engine to the drive wheels.

First-Generation: 2014-2016 Accord Hybrid In the U.S. market, the Honda two-motor hybrid system debuted in the 2014 Accord Hybrid with a combined output of 196 hp, and EPA-estimated fuel economy rating of 49 mpg city, 45 mpg highway and 47 mpg combined .

The propulsion motor linked to the drive wheels generates 166 horsepower and 226 lb.-ft. of torque. The hybrid system’s 2.0-liter i-VTEC® Atkinson cycle 4-cylinder engine puts out 141 hp (SAE net at 6,200 rpm) and 122 lb.-ft of torque (SAE net at 3,500-6,000 rpm).

Located behind the rear seat, the IPU combines a 1.3 kilowatt-hour (kWh) Li-Ion battery and control hardware, along with the DC/DC converter. The PCU is located under the hood above the two-motor unit. With up to 12.7 cu.-ft. of trunk space, Accord Hybrid offered competitive cargo space for its class.

Second-Generation: 2017 Accord Hybrid The second generation of the two-motor hybrid system featured more fully optimized motors. Both the generator and propulsion motors featured square copper wire and a new method of winding that increased the density factor from 48% to 60%. The result was smaller and 23% lighter motors that were nonetheless more powerful than their predecessors.

In the propulsion motor, three smaller and lighter magnets were arranged in an arc to create six magnetic poles, as opposed to the two-magnet arrangement of the first generation. This new arrangement improved torque multiplication, increasing the propulsion motor’s maximum power to 181 hp, and torque to 232 lb.-ft. Power and torque also increased for the 2.0-liter engine to 143 hp (SAE net at 6,200 rpm) and 129 lb.-ft. (SAE net at 4,000 rpm), gains of 2 hp and 7 lb.-ft. Peak combined output climbed to 212 hp.

When it debuted, the 2017 Accord Hybrid was the most powerful and most fuel-efficient hybrid in its class, with an EPA-estimated fuel economy rating of 49 mpg city, 47 mpg highway and 48 mpg combined.

Still located behind the rear seat and containing a 1.3 kWh Li-Ion battery pack, the IPU provided the same capacity and output as before, but in a more compact and lighter package. By utilizing VDA-standard high energy density Li-Ion battery cells, unifying the battery ECU and cell voltage sensor into one component, and using a single rather than dual cooling duct, overall volume of the IPU was reduced by more than 30% from 3.32 to 2.26 cu.-ft., with a nearly 13% weight reduction, from 113.8 lbs. to 99.2 lbs. The smaller size of the IPU also helped increase trunk capacity to 13.5 cu.-ft.

Likewise, the PCU was upgraded with a new design that reduced the component weight by 27% and reduced its size by 23%. Additional size and weight was saved by mounting the PCU directly to the two-motor unit, reducing the number of components compared to the previous two-motor system by eliminating the mounting bracket.

Third-Generation: 2018-2022 Accord Hybrid More refined and compact, the third-generation of the two-motor system debuted in the 2018 Accord Hybrid with EPA-estimated fuel economy rating of 48 mpg city and 47 mpg for highway and combined.

The IPU was again reworked, making it 32% smaller than its predecessor. Part of the size reduction came from relocating the DC/DC converter from the IPU as it was in earlier versions of the two-motor hybrid system, to the PCU mounted above the transmission. By shrinking the IPU, engineers were able to relocate the unit under the rear seat base instead of the trunk giving Accord Hybrid the same roomy trunk and 60/40 split-folding rear seatback versatility of the non-hybrid Accord models.

Along with the size reduction, the new IPU features improved battery control systems and revised battery chemistry, allowing it to operate over a broader state-of-charge range for improved efficiency.

The 2.0-liter gasoline engine features a slightly higher compression ratio (13.5:1), which resulted in moving the torque peak of 129 lb.-ft. (SAE net) from 4,000 rpm down to 3,500 rpm while maintaining a horsepower peak of 143 hp at 6200 rpm (SAE net).

Based on a proprietary, jointly patented Honda and Daido Electronics design, the system’s two next-generation electric motors were upgraded with new permanent magnets with no heavy rare-earth metals. Peak output remains at 181 horsepower and 232 lb.-ft. of torque.

To give the driver more control over electric regeneration, Accord Hybrid includes steering wheel-mounted selector paddles that allow the driver to choose between four levels of regenerative braking performance.

Third-Generation: 2019-2022 Insight Though based on the third-generation two-motor hybrid system found in Accord, Insight used components optimized for the smaller compact sedan.

Insight used a 1.5-liter DOHC i-VTEC® 4-cylinder Atkinson-cycle engine, putting out 107 hp (SAE net at 6,000 rpm) and 99 lb.-ft. of torque (SAE net at 5,000 rpm). In addition to the regen paddles from Accord, Insight featured a “click point” at roughly the three-quarter-point of pedal travel. Drivers could push past the “click point” to deliver full power from the engine and electric motor for maximum acceleration, regardless of driving mode.

The propulsion and generator motors were less powerful than those found in Accord, but feature similar square-wire, winding, and rare-earth-metals-free magnet technologies. The propulsion motor was rated at 129 horsepower and 197 lb.-ft. of torque. Combined total output for the system was 151 horsepower, and Insight achievedup to an EPA-estimated fuel economy rating 55 mpg city, 49 mpg highway and 52 mpg combined.

Insight’s compact IPU with its 1.2 kWh battery was positioned under the rear seat base, giving it the same roomy trunk and folding rear seatback versatility of a conventional non-hybrid sedan. The PCU was mounted in the engine compartment above the two-motor assembly and includes the DC/DC converter.

Third-Generation: 2020-2022 CR-V Hybrid The first-ever hybrid SUV from Honda, CR-V Hybrid used a two-motor hybrid system based on the system utilized by the Accord Hybrid, and combined it for the first time with an all-wheel drive system. CR-V Hybrid was the most fuel-efficient CR-V ever, with an EPA-estimated fuel economy rating of 40 mpg city, 35 mpg highway and 38 mpg combined. With a combined output of 212 horsepower, it was also the most powerful CR-V ever when it was introduced.

Similar to Accord Hybrid, the 2.0-liter DOHC i-VTEC® 4-cylinder Atkinson-cycle engine developed a peak 143 hp (SAE net at 6,200 rpm) and 129 lb.-ft. of torque (SAE net at 3,500 rpm. The propulsion motor was rated at 181 hp and 232 lb.-ft. of torque. To give the driver more control over electric regeneration, CR-V Hybrid also included the steering wheel-mounted selector paddles introduced with Accord Hybrid.

For CR-V Hybrid, the IPU with its 1.4 kWh battery was located below the cargo floor, giving it similar cargo utility and the same 60/40-split dive-down and fully-flat folding second-row seats as the non-hybrid CR-V. As with Accord Hybrid, the DC/DC converter was integrated with the PCU in the engine compartment.

CR-V Hybrid was the first Honda model using the two-motor hybrid system to feature Real Time AWD with Intelligent Control System™. The compact and efficient system was entirely mechanical to provide a high degree of control and driving confidence in rain, snow, dirt roads and on dry pavement. A multi-plate clutch connected the propeller shaft to the rear differential and was engaged by a hydraulic pump operated by an electric motor. The system minimized wheel spin under acceleration by proactively sending power to the rear wheels. When AWD was not required, such as when cruising, all drive force was sent to the front wheels to increase efficiency.

EPA-Estimated Fuel Economy (City/Highway/Combined)2

2.0-liter i-VTEC® 141 hp @ 6200 rpm 122 lb.-ft. @ 3500-6000 rpm

2.0-liter i-VTEC® 143 hp @ 6200 rpm 129 lb.-ft. @ 4000 rpm

2.0-liter i-VTEC® 143 hp @ 6200 rpm 129 lb.-ft. @ 3500 rpm

1.5-liter i-VTEC® 107 hp @ 6000 rpm 99 lb.-ft. @ 5000 rpm

2.0-liter i-VTEC® 143 hp @ 6200 rpm 129 lb.-ft. @ 3500 rpm

2.0-liter i-VTEC® 145 hp @ 6100 rpm 138 lb.-ft. @ 4500 rpm

2.0-liter i-VTEC® 146 hp @ 6100 rpm 134 lb.-ft. @ 4500 rpm

Diesel Power Unit 1 Calculated using more stringent ratings enacted by the U.S. EPA for the 2017 model year. Original EPA rating 50/45/47 2 Based on 2022 EPA mileage ratings; Use for comparison purposes only; your mileage will vary depending on how you drive and maintain your vehicle, driving conditions, and other factors 3 Hybrid, EX-L 4 Sport, Touring 5 EX 6 Touring