For something that’s basically a coil of wire around some magnetic pole pieces, an electric guitar pickup is a complicated bit of tech. So much about the tone of the instrument is dictated by how the pickup is wound that controlling the winding process is something best accomplished with a machine. This automatic pickup winder isn’t exactly a high-end machine, but it’s enough for the job at hand, and has some interesting possibilities for refinements.

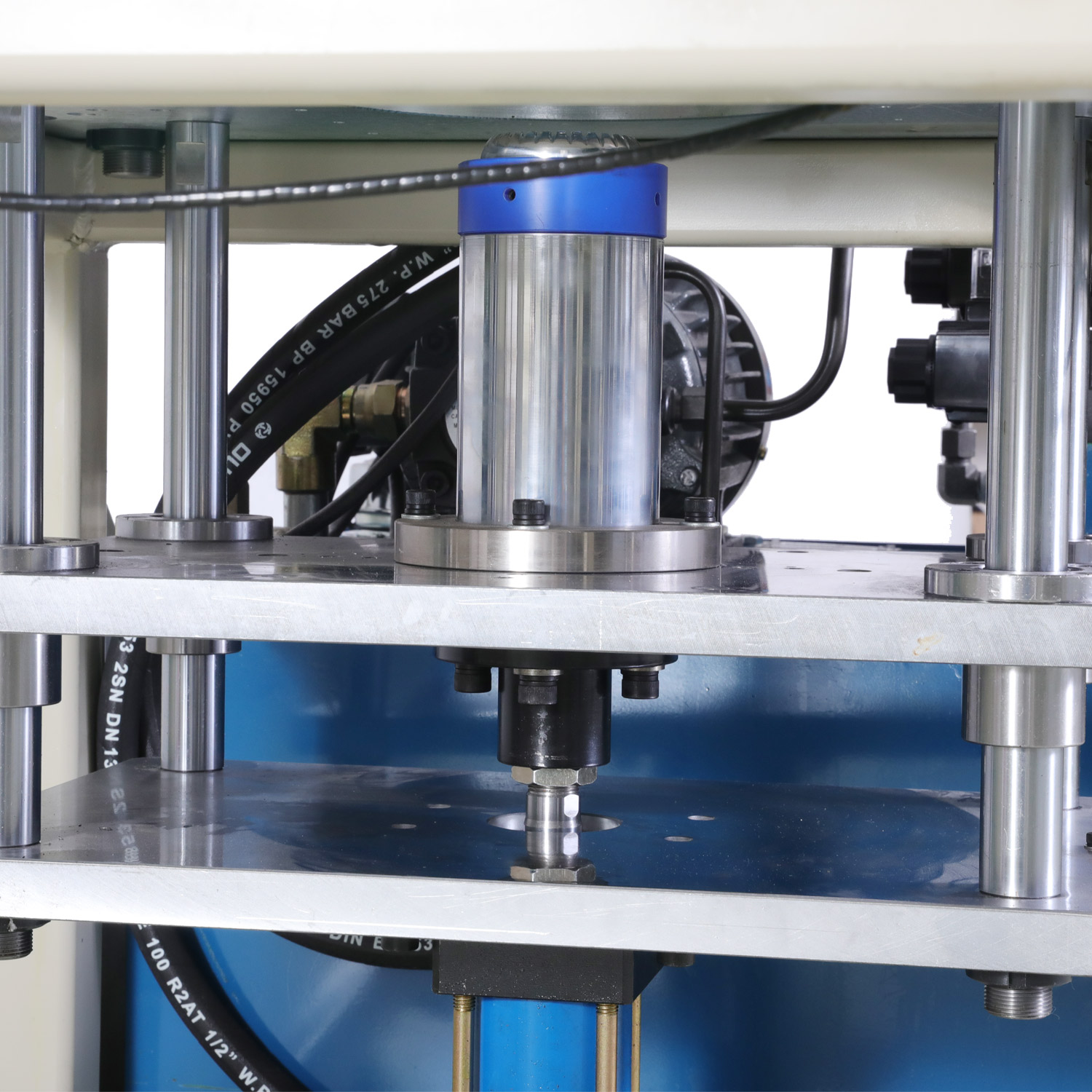

First off, as [The Mixed Signal] points out, his pickups aren’t intended for use on a guitar. As we’ve seen before, the musical projects he has tackled are somewhat offbeat, and this single-pole pickup is destined for another unusual instrument. That’s not to say a guitar pickup couldn’t be wound on this machine, of course, as could inductors, solenoids, or Tesla coils. The running gear is built around two NEMA-17 stepper motors, one for the coil spindle and one for the winding carriage. The carriage runs on a short Acme lead screw and linear bearings, moving back and forth to wind the coil more or less evenly. An Arduino topped with a CNC shield runs the show, allowing for walk-away coil winding. Motor Coil Winding Machine

We do notice that the coil wire seems to bunch up at the ends of the coil form. We wonder if that could be cured by speeding up the carriage motor as it nears the end of the spool to spread the wire spacing out a bit. The nice thing about builds like these is the ease with which changes can be made — at the end of the day, it’s just code.

https://www.youtube.com/watch?v=_2iHD2RhGzs

The coil bunching at the ends is only because the carriage over travels the ends of the spool.

An adjustable ratio pantograph feed arm would do wonders for accurate placement of the windings on the pickup spool, and would allow for various size end products.

I’ve seen roughly 23,750 articles on how to build a winder and about 2 actual pickups. This leads me to believe that the winder is the end product rather than a pickup. So, how do these things mount on the guitar and how do they sound?

They don’t mount on a guitar.

Is slack control being addressed here? More tension during winding causes the bottom layers of the coil to short out eventually. The pressure adds up with the layers. This one reason for slow and easy winding with a computer to do it overnight.

I have a one string slide guitar. The beeper on motherboards and such is a coil and magnet with a diaphragm like old school headphones. Peel the top of the housing off with the disc and you have a single pickup with magnet and pot magnet housing ready to go.

I tried and used this in my self sustaining design till I gave up because of feedback between the pickup and putdown coils. As the putdown has to be magnetic the pickup went piezo first then to a bridge mic. No feedback except thru the string itself. I would like to go to 4 strings like a pedal steel and will try the beeper coils again to do each string separately, just not as high up of a range as the solo instrument.

Looking at the coil being wound, it appears that the coil winding speed is constant while the slider that distributes the wire on the bobbin has deceleration/acceleration. That leads to uneven winding with the middle being thinner than the ends. The coil stepper needs track the acceleration of the slider.

Honestly, you would be better served using something like Grbl to control this as it would make sure the two steppers stay in snyc.

That’s a simple matter of software!™

Please be kind and respectful to help make the comments section excellent. (Comment Policy)

This site uses Akismet to reduce spam. Learn how your comment data is processed.

Coil Shaping Machine By using our website and services, you expressly agree to the placement of our performance, functionality and advertising cookies. Learn more