This issue previews many of the important events taking place at this year's show and highlights some changes and opportunities. So, buckle up. We are counting down to IPC APEX EXPO 2024.

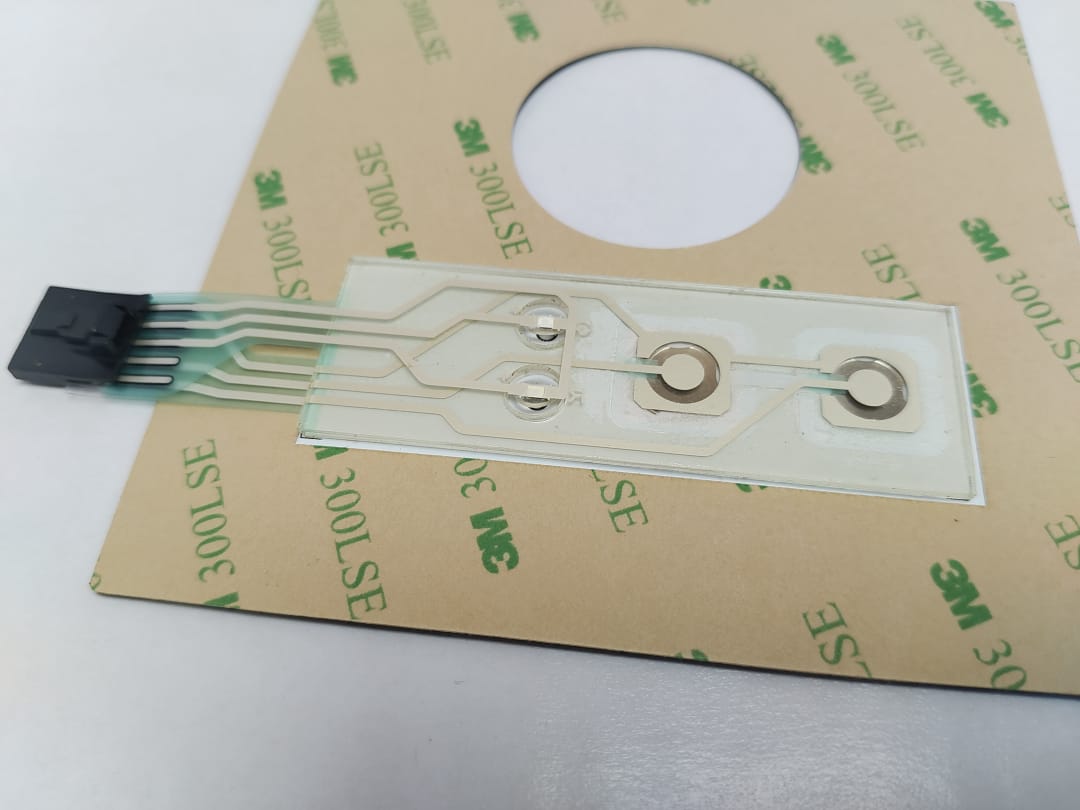

In this issue, we examine how fabs work with their design customers, educating them on the critical elements of fabrication needed to be successful, as well as the many tradeoffs involved. How well do you really know your customer? What makes for a closer, more synchronized working relationship? Membrane Keyboard Switch

In this issue, the biggest names in PCB manufacturing share their economic outlook for the upcoming year and beyond. As you will see, they were all bullish on our industry, but there was some apprehension as well. No one wants to get burned by another the supply chain disruption.

With the use of sensors and technology in everything from mobile phones to refrigerators, automobiles, and wearable medical devices, circuit boards are a component in many different types of products. In today’s world of electronics, any product with an on-off switch contains a circuit board.

Due to their versatility, the use of flex circuits is one of the fastest growing product market segments. With the introduction of flex and rigid-flex circuits, engineers have been given the opportunity to be more creative in designing new and innovative products. Flex and rigid-flex boards are built to fit into tight, threedimensional spaces while ensuring resistance to mechanical wear and vibration. Engineers can design products that require boards to fit into tight spaces, twist and turn for packaging, and make the product live in a more dynamic environment. These flexible circuits have the same performance levels as traditional rigid FR-4 boards; however, they have their own nuances and considerations when it comes to design, fabrication, and assembly.

When designing a flex circuit, it is important to know the specific application for the circuit. Will it be used in a static or dynamic environment? If the board will reside in a static environment with little to no movement, the circuit design needs to have the appropriate amount of flexibility so that it can be easily installed within the product. Alternatively, if the board will exist in a dynamic environment where the board will continuously flex back and forth, a level of flexibility that can withstand continuous movement needs to be considered in the design.

Will the application require a flex or a rigidflex circuit? If the product requires one-sided surface-mount technology, then a fully flexible board may be the best option. If the product requires two-sided SMT, then a rigid-flex board is needed.

Custom Graphic Overlays To read the full version of this article which originally appeared in the October 2018 issue of Flex007 Magazine, click here.