By Tania Concejo, Senko Advanced Components Inc., and Hirokazu Takeuchi, Nippon Electric Glass Co. Ltd. A recently developed ferrule technology offers comparable performance to other ferrule materials at much lower manufacturing costs. Fiber-to-the-business and -home, is the optimum technology to support growing data-transport demand. Prohibitive cost, however, is still a deciding factor against this practical setup. In light of this dilemma, several innovations in fiber and optical-component technology have resulted from developers' desire to promote fiber-optic communications by enabling cost-reduction measures without sacrificing performance. A new glass-ceramic ferrule technology developed for high-performance, low-cost optical connectors accomplishes both these objectives.

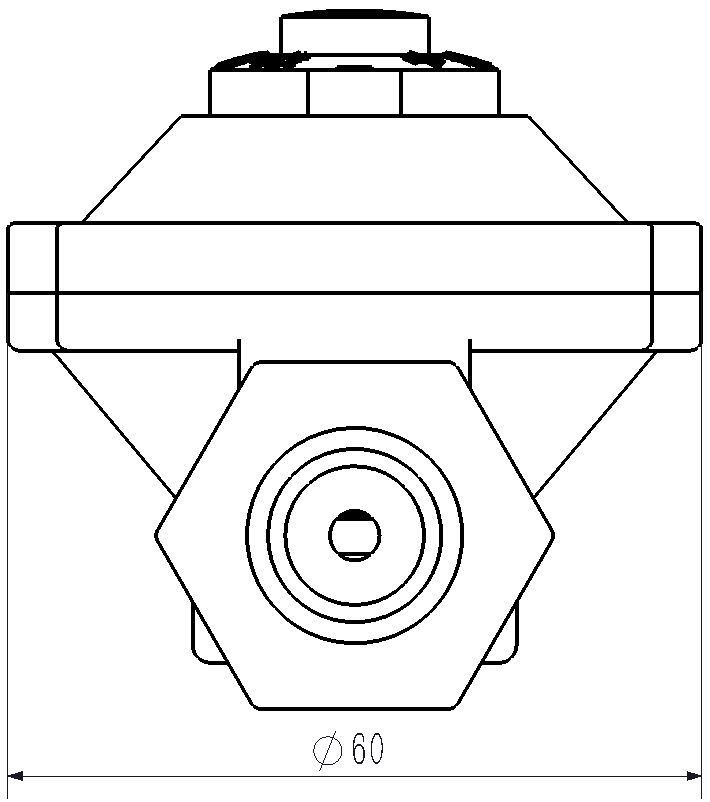

The most expensive part of an optical connector is the ferrule. Until now, only zirconia ferrules achieved the required performance and quality level--at a high cost for the component and its required polishing process. Remote Valve Controller

The test series described here shows that the glass-ceramic ferrule's performance offers the same level of insertion/return loss, durability, and reliability as the zirconia ferrule. Further, this new ferrule type is proven to be suitable for both singlemode and multimode applications.

During the manufacturing process, the conventional zirconia ferrules require precise and lengthy polishing to obtain accurate inner and outer diameters. The glass-ceramic ferrule only needs to be cut to a proper length, machined at both ends--outer chamfering at the top and inner chamfering at the bottom--and attached to the flange. It requires no polishing.

Test results also indicate that the glass-ceramic ferrule's expansion coefficient of 2.7 parts-per-million (ppm)/C is much lower than for other materials used for ferrules (see Table 1). This physical stability is an advantage, indicating highly reliable contact between optical connectors that use glass-ceramic ferrules. Moreover, the stress caused by differences in the thermal expansion of the ferrule and the fiber is minimized because both use glass material.

The glass-ceramic ferrule's hardness measurement is also lower than its alumina and zirconia counterparts (see Table 1). The lower Vicker's hardness measurement indicates that the glass-ceramic ferrule is softer than other ferrule materials, which enables easier polishing and facilitates optical-connector assembly.

Under these conditions, polishing costs can be reduced dramatically, especially when compared to conventional zirconia ferrules. Overall polishing time is shortened even if the glass-ceramic ferrule only requires alumina or chromium polishing film; it does not require diamond polishing film. Cost reduction is further achieved by the glass-ceramic manufacturing process, which uses the thermal softening properties of glass. Consequently, this new type of glass-ceramic ferrule allows a low-cost fabrication process compared to that of zirconia.

In the second part of the test series, the performance of optical connectors assembled with glass-ceramic ferrules was analyzed. The glass-ceramic ferrules for singlemode fiber were used in SC connectors.

The glass-ceramic ferrule endfaces were polished using an inexpensive physical contact (PC) polishing film. The alumina polishing consists of three steps: epoxy removal, polishing, and finishing. The time required for the whole alumina polishing process is 400 sec, which is shorter than the 400 sec needed for zirconia polishing with diamond. Test results demonstrated that glass-ceramic ferrules polished with low-cost alumina film have an average insertion loss of 0.06 dB and an average return loss of 50 dB. These performance measurements are similar to those of zirconia ferrules polished with expensive diamond film.

The test results demonstrate that a glass-ceramic ferrule is equivalent to a zirconia ferrule in terms of performance. When assembled in an SC connector, the glass-ceramic ferrule offers an average insertion loss (0.06 dB), an average return loss (50 dB), and reliability that is comparable to the performance of a conventional zirconia ferrule. Moreover, with the glass-ceramic ferrule, significant cost reductions are achieved due to the minimum polishing required. Thus, the glass-ceramic ferrule is suitable for singlemode and multimode applications where zirconia ferrules are currently in use.

The development of this low-cost optical-component technology is significant because it may accelerate the adoption of fiber in future technologies and applications. It has the potential to be widely used in fiber-to-the-home and in business networks.

Shut Off Gas Stove Valve Tania Concejo is a marketing coordinator at Senko Advanced Components Inc. (Southboro, MA). She can be reached at [email protected]. Hirokazu Takeuchi is the manager of the electronic product division at Nippon Electric Glass Co. Ltd. in Japan.