Solar tracker supplier Nextracker and provider of industrial manufacturing and supply chain solutions Unimatics have opened a manufacturing facility in Las Vegas, Nevada.

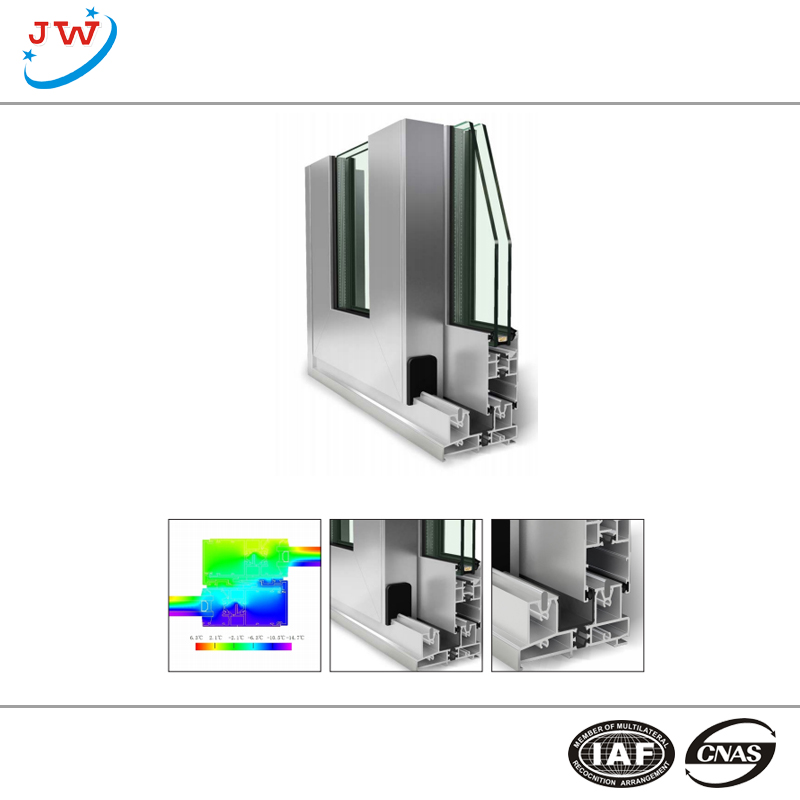

PV Tech was in attendance at the event yesterday, which was held to coincide with the opening day of the RE+ multi-technology clean energy trade show taking place elsewhere in the US city. Tension Rod Curtain Wall

This new facility follows a suite of domestic production lines across the US, from Texas, to Arizona, passing by Tennessee, among other locations, with the factory in Las Vegas dedicated to producing critical steel components for Nextracker.

“It’s critical to be where the projects are, and the projects now are everywhere in the US,” said to PV Tech Howard Wenger, president of Nextracker. Being as local as possible also helps reduce the timeframe to deliver the product to the solar plants once these are ready to be distributed.

The pace at which the California-based company has been opening facilities across the country has been boosted thanks to the implementation of the Inflation Reduction Act (IRA) last year.

“Prior to the IRA we started to mobilise here, but the IRA certainly has given us the fuel to go even faster,” said Wenger. With the company putting in place 15 domestic manufacturing facilities in the US in the last couple of years, added Wenger.

In total, the California-based PV tracker supplier has invested in over 25GW of annual solar tracker manufacturing capacity.

The latest plant in Nextracker’s domestic manufacturing expansion is expected to create more than 100 new jobs and double that number by 2024, with another production line already in the pipeline, near the current location, according to Matt Arnold, CEO of Unimacts.

The opening ceremony was held on the same day as the start of the US largest solar industry event, RE+ which is hosted in Las Vegas this week and only a few minutes away from the exposition center.

“By partnering with Unimacts on this new production line, we’re bringing back American manufacturing jobs and building out America’s energy infrastructure to enhance energy security and de-risk the supply chain,” said Dan Shugar, founder and CEO of Nextracker. “This plant will support our customers with quick shipping and American-made products.”

Proximity to projects is a key element to offer faster delivery and this is why this new factory in Las Vegas will primarily serve projects in the state of Nevada as well as southwestern states in the US.

The tubes that are made in the Nevada facility in the end represent 80% of the weight of a tracker, which in itself requires three aspects, said Wenger. Proximity to projects, manufacturing capacity and ability to ramp and serve the need.

As Nextracker adds more facilities to build the trackers and its components, it now has a 25GW annual manufacturing capacity.

Insulated Curtain Wall “Nextracker and Unimact’s new facility is a shining example of how smart policy can uplift communities with jobs and local investment,” said Abigail Ross Hopper, president and CEO of the Solar Energy Industries Association (SEIA). “The United States is in the midst of a clean energy manufacturing renaissance, and investments like this are helping drive us toward an abundant, reliable, American-made clean energy future.”