Minn-Dak Farmer’s Cooperative is a 40-year-old cooperative producing sugar from locally grown sugar beets at a plant in Wahpeton, ND. Based on market demand, Minn-Dak decided to expand its sugar beet processing facility in 2012 by adding the capabilities to provide granulated sugar in 80-cu-ft bulk bags, and to provide a truck load-out facility. The new facility was also to include a sugar milling operation. Because of space constraints, the site for this new processing facility required that it had to be located nearby, but about 1200 ft from the plant’s main and existing processing and storage facilities. Minn-Dak required that all new equipment provided had to be of a sanitary design and be totally enclosed to control any infiltration of moisture, etc. The equipment also had to be robust enough to be able to convey the granulated sugar from the existing processing and storage facilities 1200 ft to the new processing site. In addition, because only some of the sugar was to be milled into powdered sugar, the balance that was not milled was to be sold in bulk bags and trucks. Another concern of Minn-Dak was that the conveying equipment chosen had to be such that it minimized any sugar degradation and adhered to tight degradation specifications. It had to be consistent with and/or exceed industry standards for particle size to insure a high-quality product. Other issues of prime importance for the equipment design were cleanliness, energy efficiency, operational cost, equipment cost, and maintenance requirements, Testing One of the first steps in the equipment selection process was to review capable manufacturers who had experience with the conveying of granulated sugar, and who had the engineering knowledge and expertise to convey granulated sugar over long distances with minimal degradation. The chosen manufacturer also had to fully demonstrate and verify the ability to achieve the contract specifications which were outlined by the customer. One of the first requirements was to be able to test the capability to convey the sugar with minimal degradation, yet with high reliability for performance and energy requirements. The testing was required to be done by the manufacturer at its testing facility. Dynamic Air was selected to test the conveying of the sugar at its test facility in St. Paul, MN. Dynamic Air then needed to determine the most applicable conveying concept as it related to the various and different conveying concepts available. The tests were to be conducted to verify which concept was best suited for this specific application as it related to the conveying distance and other technical issues. Characteristics such as product degradation and segregation were a primary concern, as was the conveying velocity, air consumption, pressure drop versus distance, conveying pressures, conveying times, and superficial exit velocities. These characteristics were all fully analyzed as a result of this preliminary testing process. It was then determined by Dynamic Air that the HDP 4000 Full Line Concept dense-phase pneumatic conveying system seemed to be the best suited for the Minn-Dak application to convey granulated sugar a distance of 1200 ft at a conveying rate of 60,000 lb/hr, and do so with minimal degradation. It was the system of overwhelming choice. However, further and more exhaustive testing had to be conducted to verify all aspects of the conveying system’s characteristics which had to meet and/or exceed the tight process system specifications and efficiencies demanded by Minn-Dak. Fortunately, Dynamic Air was able to achieve the lower product degradation levels as specified in the initial bid specifications, and it was demonstrated to the full satisfaction of Minn-Dak that Dynamic Air could meet and/or even exceed their design requirements. After extensive conveying testing of Minn-Dak’s granulated sugar was completed, a second analysis of all the tested material was conducted in tandem by Minn-Dak’s technical staff to reaffirm the energy requirements and acceptable degradation levels and other issues of concern. The Design and Solution Final results confirmed that the HDP 4000 Full Line Concept dense-phase pneumatic conveying system was the best design suited for the Minn-Dak application. It was then determined that a large 14-in.-diam conveying line would be required to achieve the conveying velocities required and to minimize degradation. This design included Dynamic Air’s exclusive Air Saver technology, which controls the compressed air injected into the conveying line. The system also had to be designed to deliver granular sugar from a large surge hopper in Minn-Dak’s existing processing facility to either of two large receiving hoppers in the new bulk bag load-out and processing facility. The HDP 4000 Full Line Concept conveying system was also the ideal choice for the high conveying rate of 60,000 lb/hr over the long 1200-ft conveying distance. With the HDP 4000 Full Line Concept system, Dynamic Air was able to achieve the desired conveying velocities as compared to a conventional system, where the conveying line is allowed to purge and higher conveying velocities are the norm. Another benefit was lower system maintenance, as this system utilized less compressed air, which also resulted in lower conveying velocities than a conventional type system. Installation costs were also reduced over conventional conveying concepts, since a 14-in. conveying line was relatively easy and simple to install and took up less space. For plant convenience considerations it was also decided to mount the large 14-in. conveying line on a bridge 30 ft above the ground to allow plant vehicles access underneath the conveying line and to avoid equipment located at ground level. The efficiency and low degradation of the HDP4000 Full Line Concept dense-phase pneumatic conveying system was easily accomplished through the use of the DC-5 Air Saver technology. The DC-5 Air Savor technology controls a precise amount of compressed air into the conveying line at discrete locations, providing for highly effective velocity control during conveying. The DC-5 Air Saver technology also provides the ability to start and stop the material in the 1200-ft-long conveying line, thus the concern of a plug in the conveying line is for the most part eliminated. Due to the extreme atmospheric temperatures at the Wahpeton, ND installation site, the expansion and contraction issue relative to this conveying line had to be considered. Therefore, Minn-Dak required adequate expansion joints to be installed throughout the conveying line. Minn-Dak chose the Tuf-Lok brand of Therm-Line expansion joints. These expansion joints have a lower coefficient of friction and minimize any leading edges that might otherwise be a concern. This allows the conveying line to expand and contract through the broad temperature ranges which can fluctuate from subzero to 100 degrees Fahrenheit or higher. The selection of the proper expansion joints was critical for optimum conveying efficiency, reliability, and the prime concern of maintaining product integrity. The destination building had some tight space constraints. Because of this, it was necessary to provide bin vent filters with a space-saving profile. The bin vent filters provided by Dynamic Air had to use a low-profile horizontal cartridge configuration in order to accommodate the space allowed. In addition, high-flow vacuum/pressure relief valves were required as a safety feature for venting the receiving hoppers under unusual and/or upset conditions. The Series 650 Quik-Vent high-flow vacuum/pressure relief valves were utilized because of their highly responsive and ultra-fast venting capability. These vacuum/pressure relief valves were set to precise air flows to accommodate the special requirements of this application. A key benefit of selecting the HDP 4000 Full Line Concept dense-phase pneumatic conveying system over a conventional mechanical conveying system such as a belt conveyor was that this pneumatic conveying system eliminated any need for idlers, pulleys, motors, drives, bearings, and other moving parts that require constant maintenance. In addition, the simplicity of the dense-phase conveying system is that the material conveyed is always completely enclosed and protected from the elements and against any outside contamination. The Results The HDP4000 Full Line Concept conveying system is now fully operational and is providing Minn-Dak with what was expected with regard to the primary issues of cost, operating efficiency, reliability, and low degradation, and is proving to be suitable for some of the harshest environments in rugged North Dakota. For more information, call 651-484-2900 or visit www.dynamicair.com .

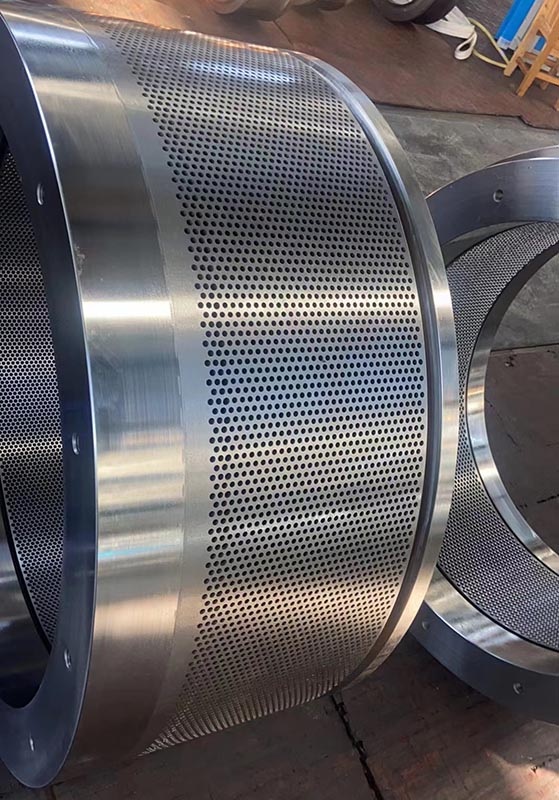

For related equipment reviews, articles, and news, visit our Pneumatic Conveying Equipment Zone Click here for information about International Powder & Bulk Solids Conference & Exhibition Roller Shell Assembly

Thayer Scale Introduces New Gravimetric Feeder

What the Final "Product of USA" Label Means

Tyson to Close Another Processing Plant

Boss Products Expands as Part of Reorganization

Pellet Mill Parts Copyright © 2024 All rights reserved. Informa Markets, a trading division of Informa PLC.