A 360-degree look at resin conveying systems: types, operation, economics, design, installation, components and controls.

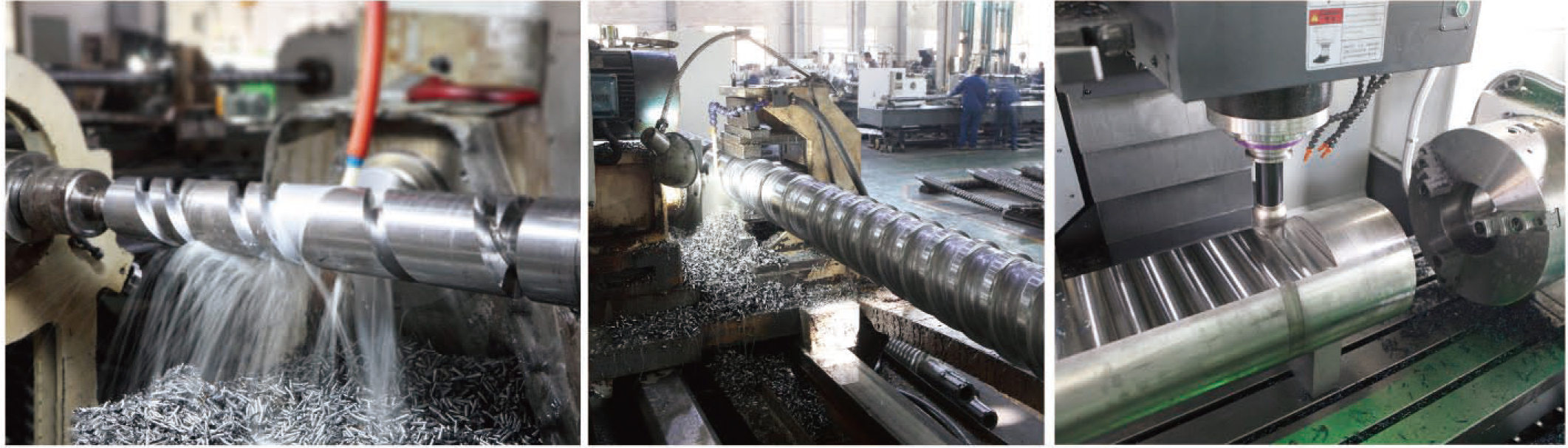

This Knowledge Center provides an overview of resin moisture and the drying process, including information on the best drying practices for your manufacturing facility. Twin Parallel Screw Barrels

Combat the skilled labor shortage using this comprehensive resource to train your own plastics processing experts.

Deep dive into the basics of blending versus dosing, controls, maintenance, process integration and more.

This Knowledge Center provides an overview of the considerations needed to understand the purchase, operation, and maintenance of a process cooling system.

Learn about sustainable scrap reprocessing—this resource offers a deep dive into everything from granulator types and options, to service tips, videos and technical articles.

First quarter was ending up with upward pricing, primarily due to higher feedstock costs and not supply/demand fundamentals.

Despite earlier anticipated rollover in prices for most of the volume commodity resins, prices were generally on the way up for all going into the third month of first quarter.

While price initiatives for PE and PVC were underway, resin prices had rollover potential for first two months of 2024, perhaps with the exception of PET.

Flat-to-downward trajectory for at least this month.

A mixed bag, though prices likely to be down if not flat for all this month.

Trajectory is generally flat-to-down for all commodity resins.

Resin drying is a crucial, but often-misunderstood area. This collection includes details on why and what you need to dry, how to specify a dryer, and best practices.

Take a deep dive into all of the various aspects of part quoting to ensure you’ve got all the bases—as in costs—covered before preparing your customer’s quote for services.

In this collection of articles, two of the industry’s foremost authorities on screw design — Jim Frankand and Mark Spalding — offer their sage advice on screw design...what works, what doesn’t, and what to look for when things start going wrong.

In this collection, which is part one of a series representing some of John’s finest work, we present you with five articles that we think you will refer to time and again as you look to solve problems, cut cycle times and improve the quality of the parts you mold.

Gifted with extraordinary technical know how and an authoritative yet plain English writing style, in this collection of articles Fattori offers his insights on a variety of molding-related topics that are bound to make your days on the production floor go a little bit better.

In this three-part collection, veteran molder and moldmaker Jim Fattori brings to bear his 40+ years of on-the-job experience and provides molders his “from the trenches” perspective on on the why, where and how of venting injection molds. Take the trial-and-error out of the molding venting process.

Mike Sepe has authored more than 25 ANTEC papers and more than 250 articles illustrating the importance of this interdisciplanary approach. In this collection, we present some of his best work during the years he has been contributing for Plastics Technology Magazine.

In this collection of content, we provide expert advice on welding from some of the leading authorities in the field, with tips on such matters as controls, as well as insights on how to solve common problems in welding.

Mold maintenance is critical, and with this collection of content we’ve bundled some of the very best advice we’ve published on repairing, maintaining, evaluating and even hanging molds on injection molding machines.

Thousands of people visit our Supplier Guide every day to source equipment and materials. Get in front of them with a free company profile.

There are many fundamental differences between thermosets and thermoplastics, from the way raw materials are furnished to the molder and the process in which parts are molded.

It’s all about sustainability and the circular economy, and it will be on display in Orlando across all the major processes. But there will be plenty to see in automation, AI and machine learning as well.

Polymer Resources responds to sustainability push by upgrading plant with grinding and shredding equipment to take on both postindustrial and postconsumer reclaim.

First quarter was ending up with upward pricing, primarily due to higher feedstock costs and not supply/demand fundamentals.

An integral supplier in the effort to fast-track COVID-19 vaccine deployment, Retractable Technologies turned to Arburg and its PressurePilot technology to help deliver more than 500 million syringes during the pandemic.

Megatrends such as sustainability are the driving force behind a slew of new product introductions at the May show. Catch up on what’s in store on the show floor right here.

With frequent purging, you can minimize serious contamination issues and get both better results and higher profits.

Realtime Robotics seeks to get more robots involved in manufacturing by addressing the biggest current barrier: programming costs.

Offerings range from recycled, biobased, biodegradable and monomaterial structures that enhance recyclability to additives that are more efficient, sustainable and safer to use.

Understand the differences between distributive and dispersive mixing, and how you can promote one or the other in your screw design.

Topping five other entries in voting by fellow molders, the Ultradent team talks about their Hot Shots sweep.

Serendipitous Learning Opportunities at PTXPO Underscore the Value of Being Present.

Introduced by Zeiger and Spark Industries at the PTXPO, the nozzle is designed for maximum heat transfer and uniformity with a continuous taper for self cleaning.

Ultradent's entry of its Umbrella cheek retractor took home the awards for Technical Sophistication and Achievement in Economics and Efficiency at PTXPO.

technotrans says climate protection, energy efficiency and customization will be key discussion topics at PTXPO as it displays its protemp flow 6 ultrasonic eco and the teco cs 90t 9.1 TCUs.

Shibaura discusses the upcoming Plastics Technology Expo (PTXPO) March 28-30

FANUC America president and CEO, Michael Cicco, presents his show opening keynote, ‘Unlocking the Potential: Robotics, AI and Automation in the New Tech Era,’ at NPE2024.

NPE2024: Cypet shows off new capabilities for its ISBM machines.

Plastics Technology and other Gardner Business Media brands are exhibiting at NPE2024. Learn about what’s ‘Covered in Plastics Technology,’ get a unique photo op and enter the #COVEREDinPT givaway.

As the government funds infrastructure improvements, a hot topic at NPE2024 – exploration of the role recycled plastics can play in upcoming projects, particularly road development.

NPE2024: Hear from industry experts at the Bottling Stage.

NPE2024: Jomar is showing its 85-S GEN II machine with beefed-up specs, in standard servohydraulic version and brand-new hybrid model.

Mixed in among thought leaders from leading suppliers to injection molders and mold makers at the 2023 Molding and MoldMaking conferences will be molders and toolmakers themselves.

After successfully introducing a combined conference for moldmakers and injection molders in 2022, Plastics Technology and MoldMaking Technology are once again joining forces for a tooling/molding two-for-one.

Multiple speakers at Molding 2023 will address the ways simulation can impact material substitution decisions, process profitability and simplification of mold design.

When, how, what and why to automate — leading robotics suppliers and forward-thinking moldmakers will share their insights on automating manufacturing at collocated event.

As self-imposed and government-issued sustainability mandates approach, injection molders reimagine their operations.

August 29-30 in Minneapolis all things injection molding and moldmaking will be happening at the Hyatt Regency — check out who’s speaking on what topics today.

Get your clicking finger in shape and sign up for all that we have in store for you in 2023.

Molding 2023 to take place Aug. 29-30 in Minnesota; Extrusion 2023 slated for Oct. 10-12 in Indiana.

In this webinar, Cold Jet will discuss some of the ways processors use dry ice such as in-machine mold cleaning at operating temperatures, de-flashing or de-burring parts, improving OEE scores, extending mold life, cleaning parts before painting, post-processing 3D printed parts, lowering GHG emissions, and monitoring and reporting the process. Agenda: Cold Jet Overview & Dry Ice 101 Understanding the Process and Fine-Tuning Techniques Case Studies: Applications in Plastics Monitoring the Process Exploring the Importance of Dry Ice Cleaning in an ESG Era

Discover possible applications in large format printing including layup tools, transport modules, film fixation devices, design components and enclosures. These are used in various industries such as automotive, aerospace, architecture and many others. Agenda: Possible applications in large format printing: layup tools, transport modules, film fixing devices, design components and enclosures. Process reliability and component quality in component production Pros and cons of the technology Sneak peek into current development projects—What will the large format printing of tomorrow look like?

Cooling time is typically the longest step of the molding process. How can you make it more productive? Learn how cooling time can be turned into production time by running two molding processes simultaneously on a single molding machine. For longer cycles, this can mean twice the productivity. In this webinar, you'll learn more about the Shuttle Mold System and how to calculate its potential productivity impacts for your application. Agenda: Learn how the Shuttle Mold System can deliver value to your business See the recent technical updates made to the system Calculate the potential impact on productivity

Turnaround time can be as low as 24 hours, although two or three days might be more typical. Rapid prototyping like this is especially useful to quickly identify critical end-use part geometries that will work in the molding process. Key components include material choice, 3D printing technology selected, use of adaptable mold bases for the mold inserts and implementation of appropriate injection molding process conditions. This presentation will review work conducted toward the assessment of a high-stiffness, high-temperature-resistant ceramic modified urethane acrylate for injection molding inserts. Agenda: Guide for 3D-printed injection mold inserts Optimization of digital light processing (DLP) printing Compatibility with various thermoplastics Real-world application success stories

Tony will address common challenges encountered at each stage and provide invaluable insights to effectively navigate these obstacles. Agenda: Bridging the gap between color and appearance: learn how to achieve harmony between the intended color and the final appearance of your plastic products. Importance of using a data-driven color management model: color measurement technology provides valuable insights and analytics that enable plastic manufacturers to optimize color formulations, troubleshoot color inconsistencies, enhance operational efficiency and drive continuous improvement in their production processes. Choosing the right toolset: gain insights into selecting the most suitable technology and processes tailored to your workflow and specific needs.

Innovative closures at the forefront of this trend have fostered a tooling evolution that enables cost-effective manufacturing of lightweight designs. Find out more about why global beverage brands are switching closures, specific design best practices and the significant merits of a mono-material package solution. Join this webinar to find out how these production changes can enable you to reach your sustainability goals and drive business growth. Agenda: The trend toward lightweight beverage closure designs The advantages of lightweight and tethered closures Why beverage brands are implementing tethered solutions even in the absence of mandates Tooling design best practices to mold today’s ultra-lightweight closure designs The merits of a mono material package solution

Every three years, leaders from almost every major industry gather at NPE to advance their businesses through innovations in plastics. The largest plastics trade show in the Americas, NPE offers six technology zones, keynote speakers, workshops and opportunities to build partnerships.

The 3D Printing Workshop @ NPE2024 – The Plastics Show, is an immersive, half-day workshop focused on the emerging possibilities for part production via 3D printing and additive manufacturing. Presented by Additive Manufacturing Media, Plastics Technology and MoldMaking Technology, the 3D Printing Workshop will build upon a successful model first introduced at IMTS 2014. Attendees will benefit from a program focused on practical applications of 3D technologies related to plastics processing. This event will conclude with a 3D Printing Industry Reception sponsored by Additive Manufacturing Media.

The Society Plastics Engineers (SPE) Extrusion Division and the SPE Eastern New England Section will co-host the Screw Design Conference-Topcon on June 19-20, 2024 @ UMass Lowell in Lowell, MA. This highly technical program will focus upon screw design principles for single and twin screw extruders with wide ranging topics relating to screw designs for feeding, melting, mixing, venting and pumping plastics products and parts. Areas of focus will include screw designs for melt temperature and gel management, gel minimization, bioplastics, recycled materials and foaming. In addition to the technical sessions, a tour of the UMass Lowel Plastics Processing Laboratories will be integrated into Day 2 of the event. This program is not just for screw designers, but to help anyone responsible for any type of extrusion operation to evaluate existing extrusion equipment; and also to prepare for future projects. Price to attend: Less than $1000! Registrations will be accepted in early 2024. Call for papers – To be considered to give a presentation, please submit a talk title and abstract on or before December 15 to: Technical Chair: Eldridge M. Mount III, e-mail emmount@msn.com Corporate sponsorships - A limited # of corporate sponsorships (15) are available on a 1st come basis. Included is a 6’ tabletop display (must fit on table), denotation in all promotional activities, and 1 no charge registration. To become a sponsor contact: Charlie Martin, Leistritz Extrusion, e-mail cmartin@leistritz-extrusion.com, cell 973-650 3137 General information: A reception on Day 1 and a tabletop display area will allow the attendees to meet and discuss state-of-the-art screw technologies with industry experts. The SPE Extrusion Division will issue a “Screw Design Certificate” to all participants who have attended the program. Students are encouraged to attend and will receive a discounted rate. For additional information contact: Program Chair: Karen Xiao, Macro Engineering, KXiao@macroeng.com

Debuting in 2010, the Parts Cleaning Conference is the leading and most trusted manufacturing and industrial parts cleaning forum focused solely on delivering quality technical information in the specialized field of machined parts cleansing. Providing guidance and training to understand the recognized sets of standards for industrial cleaning, every year the Conference showcases industry experts who present educational sessions on the latest and most pressing topics affecting manufacturing facilities today. Discover all that the 2022 Parts Cleaning Conference has to offer!

Presented by Additive Manufacturing Media, Plastics Technology and MoldMaking Technology, the 3D Printing Workshop at IMTS 2024 is a chance for job shops to learn the emerging possibilities for part production via 3D printing and additive manufacturing. First introduced at IMTS 2014, this workshop has helped hundreds of manufacturing professionals expand their additive capabilities.

Tobe Packaging’s breakthrough was to create its Ecolefin PE multilayer film that could be applied with a specialized barrier coating.

Exceed S mLLDPE is a major part of the Ecolefin all-PE structure as is Aegis’s OX2 barrier coating. Photo Credit: ExxonMobil Chemical and Tobe Packaging

Within the last two years, Singapore’s Tobe Packaging aimed to develop an all-PE multilayer film structure for food packaging that would not fall short in offering the same kind of protective barrier of multimaterial food packaging, and would be much easier to recycle.

The film processor’s breakthrough was an all-PE structure to which a specialized barrier coating can be applied. In August 2022, the company’s Ecolefin was certified as 97% recyclable by Germany-based Institute cyclos-HTP, one of Europe’s leading and recognized organizations for recyclability testing and certification. A month later, when Tobe launched Ecolefin at the international FHA-Food & Beverage Exhibition, interest was sparked from multinational food companies from the United States, South Korea, Switzerland, Spain and Australia.

All this is thanks to its close collaborations with ExxonMobil Chemical, and its specialized PE film resins, most notably its new Exceed S mLLDPE, and Singapore’s Aegis Packaging, which developed and supplied a specialized O2X barrier coating. The development was headed by Tobe packaging director Lim Zie Hui, whose father established packaging business Lension in 1976, and acquired Tobe in 2019.

Founded in 1987 as a manufacturer of custom PE and PP bags, Tobe branched into flexible packaging in the late ’90s adding more variety of packaging pouches and multilayer packaging for food (including pet food) as well as nonfood packaging such as medical, semiconductor and hygiene products.

Tobe, which has now expanded its products and services beyond Southern Asia to places like Sri Lanka, currently has blown film extruders, printing machines, lamination machines, slitting and bag making machines. Before the end of 2023, the company will be installing two new machines: a printing machine which can operate using water-based ink (as it is more environmentally friendly) and a new coating machine.

Says Lim, “Exceed S is a major part in the Ecolefin solution, which provides balanced stiffness and toughness of full PE-laminated structure. Aside from Exceed S, we also utilize the Exceed series mLLDPE to enhance the film sealing performance and the Enable series mLLDPE to improve the film stiffness.”

Tobe Packaging is initially using Ecolefin for frozen food, chilled food and vacuum packaging, but is aiming to “tweak the material’s formula” to better suite different products such as easy-to-open snack packaging.

Ecolefin is said to be well suited for frozen food, chilled food and rice packaging. Ecolefin is used to replace the incumbent multilayer laminated structure, particularly nylon and PE laminated film — more specifically, nylon 6 used as a barrier and LDPE used as sealant. The O2X barrier coating developed by Aegis is applied on the film, and Tobe has invested in its own specialized coating machine which will be commissioned by fourth quarter 2023.

Ecolefin’s oxygen barrier is about eight times better than that of the previous film structures. This translates to longer shelf life for food packaged in Ecolefin. Tobe is currently using a third party laboratory to conduct tests to determine how long the material can prolong the shelf life of different food products.

According to Lim, Ecolefin is 10% to 15% higher in cost than nylon 6/LDPE alternative. However, considering the sustainability advantage it offers, Ecolefin presents the opportunity to achieve multiple benefits. With its ability to be sealed at lower temperature, customers can save on electricity consumption and contribute to reducing their carbon footprint. In addition, its monomaterial composition facilitates convenient recycling, further enhancing its eco-friendly attributes.

Tobe is also aiming to design other packaging options, including stand-up pouches, and to “tweak the material’s formula” to better suit different products, such as snack packaging that is easier to open. As it moves ahead with Ecolefin, the company is exploring how to further its sustainability efforts and bottom line, including the recycling of food packaging into products such as trash bags, by working with supermarkets and third-party collectors.

DSM Engineering has expanded its Medical Care portfolio of engineering materials for medical devices.

Going up against companies with as much as double its capacity, young stretch-film processor Zummit believes that new technology — notably 59-nanolayer films — will give it a competitive edge.

The Tier One automotive supplier with compounding and blowmolding machine capabilities adds the 50-yr-old molder and moldmaker.

Pregis went big and bold with investment in a brand-new, state-of-the-art plant and spent big on expanding an existing facility. High-tech lines, well-known leadership and a commitment to sustainability are bringing the “wow” factor to blown film.

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Extruder Barrel Plastics Technology covers technical and business Information for Plastics Processors in Injection Molding, Extrusion, Blow Molding, Plastic Additives, Compounding, Plastic Materials, and Resin Pricing. About Us