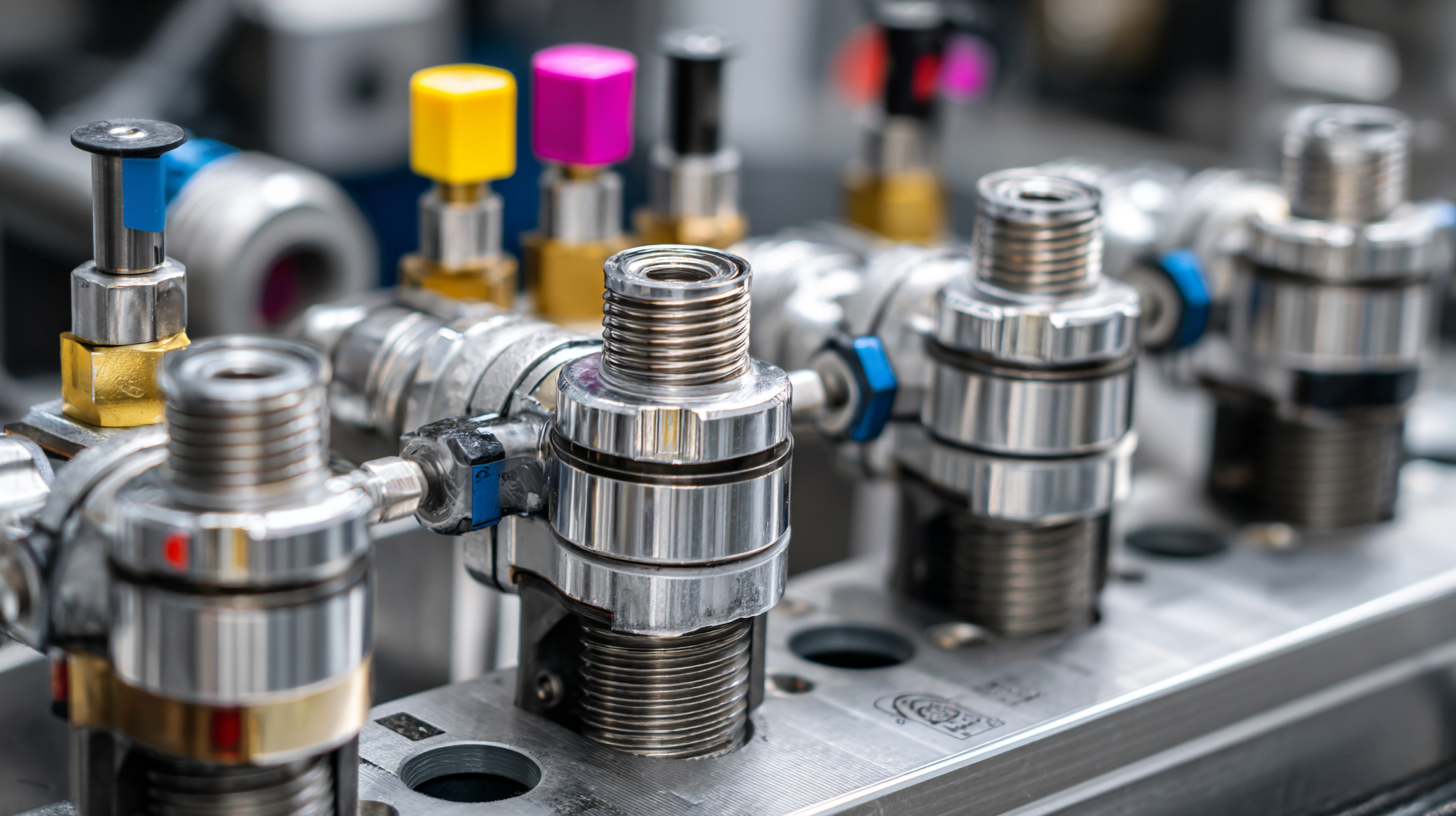

In the rapidly evolving landscape of industrial automation technologies, Pneumatic Fittings play a crucial role in enhancing operational efficiency and reliability. As industries increasingly shift towards automation, the significance of these components, which facilitate the connection of pneumatic systems, cannot be overstated. According to Dr. Emily Carter, a leading expert in pneumatic technologies, “The integration of advanced pneumatic fittings is essential for optimizing performance and meeting the demands of modern automation applications.”

This statement underscores the pivotal function that pneumatic fittings serve in ensuring seamless communication within automated systems, contributing to smoother workflows and reduced downtime. Furthermore, with the advent of Industry 4.0 and the Internet of Things (IoT), the future of pneumatic fittings appears promising, as innovations continue to expand their capabilities and applications. Understanding the dynamics of this industry is crucial for professionals seeking to leverage these advancements effectively and maintain a competitive edge in an increasingly automated world.

As we explore the future of pneumatic fittings in industrial automation technologies, it becomes imperative to examine current trends, emerging technologies, and potential challenges that stakeholders may face. By delving into these aspects, we aim to highlight the transformative impact of pneumatic fittings on the automation landscape and chart a course for future developments within this vital industry.

As industrial automation continues to evolve, the demand for pneumatic fittings is witnessing a paradigm shift toward greater efficiency and adaptability. Future trends indicate that manufacturers are focusing on lightweight materials and compact designs that enhance installation flexibility while reducing space requirements. This shift not only facilitates easier integration into existing systems but also supports the growing trend of modular automation solutions, allowing for quicker adjustments and expansions in production lines.

Additionally, the integration of smart technologies into pneumatic systems is poised to revolutionize their functionality. With advancements in IoT (Internet of Things), sensors embedded within pneumatic fittings can provide real-time data about system performance, thereby enabling predictive maintenance and minimizing downtime. This data-driven approach not only maximizes operational efficiency but also aligns with sustainability goals, as optimized systems can lead to lower energy consumption and waste reduction in industrial processes. As such, the future of pneumatic fittings in industrial automation is not just about better performance but also about smarter, more sustainable practices.

The integration of IoT technologies in pneumatic systems represents a significant advancement in the field of industrial automation. As the market for pneumatic tools is projected to reach $15.69 billion by 2025 and $18.69 billion by 2035, the demand for advanced pneumatic solutions is clear. This growth opens avenues for leveraging intelligent connectivity, allowing for real-time monitoring and management of pneumatic systems. The ability to gather data from sensors embedded within pneumatic fittings can dramatically enhance system efficiency and operational reliability.

Moreover, the global cylinder market is also poised for considerable expansion, with an estimated value of $2.195 billion in 2025, growing to $3.318 billion by 2033. This growth rate of 5.3% reflects the increasing integration of smart technologies in manufacturing environments. By adopting IoT-enabled pneumatic systems, companies can optimize their workflows, reduce downtime, and improve maintenance protocols, leading to a more streamlined production process. The ongoing evolution of pneumatic systems, driven by IoT integration, signals a promising future for industrial automation technologies.

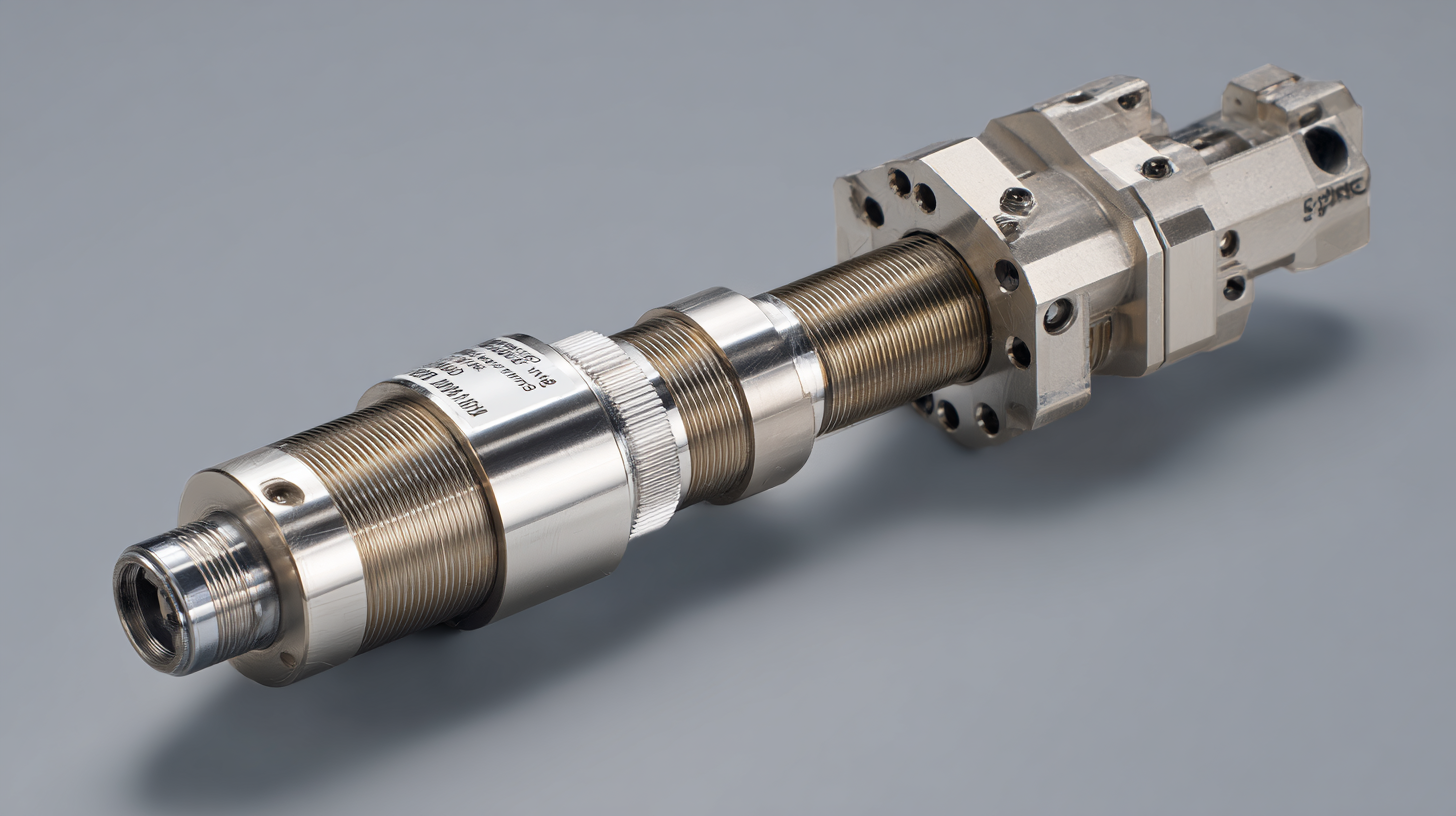

The future of pneumatic fittings in industrial automation technologies hinges significantly on advancements in material science. As industries adopt higher standards of efficiency and longevity, the materials utilized in pneumatic fittings must undergo rigorous enhancement to meet these demands. Innovations such as the development of high-performance polymers and composites can significantly improve resistance to wear, corrosion, and extreme temperatures, thereby extending the lifespan of these essential components in manufacturing systems.

Moreover, the integration of nanotechnology in material formulations is poised to revolutionize the performance characteristics of pneumatic fittings. By infusing traditional materials with nanoparticles, manufacturers can create fittings that boast not only superior mechanical strength but also enhanced flexibility and reduced weight. This shift towards advanced materials not only supports increased operational efficiency but also contributes to sustainability efforts through reduced resource consumption and waste generation. Ultimately, these advancements in material science will pave the way for more reliable and efficient pneumatic systems in the landscape of industrial automation.

This chart illustrates the advancements in material science for pneumatic fittings over the past decade, with a focus on durability improvement.

The integration of artificial intelligence (AI) into pneumatic automation is revolutionizing industrial processes, making them smarter and more efficient. AI can analyze data in real time, enabling predictive maintenance and optimizing the performance of pneumatic systems. By leveraging machine learning algorithms, industries can identify patterns and anomalies in air pressure levels, ensuring that pneumatic fittings operate smoothly and reducing downtime significantly.

Tips: When implementing AI in pneumatic systems, start with a clear understanding of your operational needs. Utilize sensors that can gather critical data points, allowing for more accurate machine learning analysis. This foundation will help you harness the full potential of AI, tailoring solutions that enhance efficiency and productivity.

AI also enhances the design and application of pneumatic fittings by enabling simulations and optimizations that were previously impossible. Engineers can utilize AI-driven software to model various scenarios, determining the best configurations for pneumatic systems in specific environments. This approach not only leads to better performance but also minimizes energy consumption and wastage.

Tips: Continuously monitor the performance of your pneumatic fittings after incorporating AI solutions. Regular assessments can help in fine-tuning the algorithms and ensuring that the automation remains aligned with your operational goals, ultimately delivering better results over time.

In the realm of industrial automation, optimizing energy efficiency is increasingly crucial, especially in the use of pneumatic fittings. These components play a vital role in the operation of pneumatic systems, which are integral to various automated processes. By enhancing the design and materials of pneumatic fittings, manufacturers can significantly reduce energy loss due to leaks and ensure smoother airflow. Innovations such as quick-connect fittings and variable flow control options contribute to more precise operations, allowing systems to consume only the energy necessary for their specific tasks.

Moreover, the integration of advanced technologies such as IoT and predictive maintenance can further optimize the performance of pneumatic systems. Sensors embedded within fittings can monitor air pressure and flow rates, providing real-time data that facilitates timely interventions. This proactive approach not only enhances energy efficiency but also prolongs the lifespan of the equipment. In essence, by embracing these technologies, industries can achieve substantial energy savings while improving overall productivity and reducing their environmental footprint.

| Application | Energy Consumption (kWh/year) | Efficiency Improvement (%) | Cost Savings ($/year) | Maintenance Frequency (times/year) |

|---|---|---|---|---|

| Automated Assembly Lines | 7500 | 15 | 1200 | 6 |

| Robotic Handling Systems | 5000 | 20 | 800 | 4 |

| Conveyor Systems | 6000 | 10 | 1000 | 5 |

| Packaging Machines | 4500 | 12 | 700 | 3 |

| CNC Machines | 8000 | 18 | 1350 | 8 |

: Future trends indicate a shift toward lightweight materials and compact designs that enhance installation flexibility and support modular automation solutions, allowing for quicker adjustments and expansions in production lines.

The integration of smart technologies, particularly IoT, will enable real-time data collection on system performance, facilitating predictive maintenance, minimizing downtime, and contributing to enhanced operational efficiency and sustainability.

Advancements in material science, including high-performance polymers and nanoparticles, are enhancing the durability and effectiveness of pneumatic fittings by improving resistance to wear, corrosion, and extreme conditions.

AI enables real-time data analysis for predictive maintenance and optimization of pneumatic systems, helping to identify patterns and anomalies to ensure efficient operations and reduce downtime.

Industries should begin with a clear understanding of their operational needs, use sensors to gather critical data, and tailor AI solutions to enhance efficiency and productivity.

AI-driven software can support simulations and optimizations, allowing engineers to explore different configurations for pneumatic systems, leading to improved performance and reduced energy consumption.

Continuous monitoring allows industries to fine-tune AI algorithms, ensuring that the automation remains aligned with operational goals and delivers better results over time.

Optimized pneumatic systems through advanced materials and smart technologies can lead to lower energy consumption and waste reduction, aligning with broader sustainability goals in industrial processes.

High-performance materials and nanotechnology enhance the mechanical strength, flexibility, and resistance of pneumatic fittings, significantly extending their lifespan in demanding environments.

Predictive maintenance utilizes real-time data to forecast potential issues, which helps minimize unexpected downtime and maintain optimal performance levels in pneumatic systems.

The future of pneumatic fittings in industrial automation is poised for significant transformation driven by several emerging trends. One major development is the integration of IoT technologies, which enhances system monitoring and control. Additionally, advancements in material science are set to improve the durability and reliability of pneumatic fittings, allowing them to withstand demanding industrial environments.

Moreover, the incorporation of AI in pneumatic automation is facilitating smart solutions, enhancing operational efficiency and predictive maintenance capabilities. Finally, optimizing energy efficiency in pneumatic fitting applications is becoming a critical focus, aligning with global sustainability goals. These trends collectively indicate a promising future for pneumatic fittings, positioning them as key components in the evolution of industrial automation technologies.