NIOSH In-house FACE Report 2001-08

A 36-year-old male paper factory worker (the victim) died from crushing injuries after being caught by the ram inside a 2-stage horizontal baling machine (Figure 1). The victim, working alone in the warehouse area of a paper plant, was compacting waste paper when at some point in the compacting process he entered (either intentionally or advertently) the compression chamber and was caught by the machine’s hydraulic ram. The victim was discovered by a coworker, who notified the plant manager to call police and emergency medical services (EMS). Silage Baler Machine

Both a fire department rescue squad and EMS arrived at the site. They extracted the victim from the baler. The victim was pronounced dead at the site by the medical examiner.

Subsequent examination by investigators revealed that the baling machine was not shut off and locked out and that the safety interlock on the compression chamber door may have malfunctioned, allowing the machine to operate with the door in the open position.

NIOSH investigators concluded that, to help prevent similar incidents, employers should

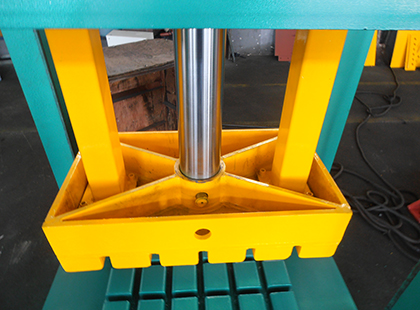

Figure 1. Two-stage horizontal baling machine.

On March 7, 2001, a 36-year-old male paper factory worker (the victim) died from crushing injuries after being caught by the ram inside a 2-stage horizontal baling machine. On March 21, 2001, the National Institute for Occupational Safety and Health (NIOSH), Division of Safety Research (DSR), was notified of the incident by the U.S. Department of Labor, Occupational Safety and Health Administration (OSHA). On April 11, 2001, a DSR occupational safety and health specialist conducted a site visit and met with representatives of the Occupational Safety and Health Administration (OSHA), the company’s insurance investigator, and the plant’s loss control manager. During the site visit, information was collected regarding the plant’s safety programs. A tour of the facility was conducted, the baling machine was observed and photographed, and information pertaining to the incident was reviewed. On May 16, 2001, the DSR occupational safety and health specialist and two DSR mechanical engineers made a second site visit to the plant to observe the baling machine in operation and to investigate the safety interlocks on the baler. During the second visit, the NIOSH/DSR representatives met with the company’s loss control manager, the OSHA inspector assigned to the incident, the company’s insurance investigators, and lawyers representing the victim’s family.

The paper company where this incident occurred had been in business at its current location for over 50 years, specializing in custom-cut paper products, including stationery, typing and copying paper, and notepads. During this investigation, the company that owned this paper plant was in the process of closing operations at that location. Many employees had already been laid off, and the only production being performed was to deplete existing inventories of stock material.

At the time of the incident, 38 employees were working the day shift (7 a.m. – 4 p.m.). The company had provided machine operators with formal training on the proper operation of machinery. The company also had a documented comprehensive written safety program with task-specific procedures for all plant tasks and written machine-specific safe operating procedures, including the control of hazardous energy by a lockout/tagout program. A management – labor safety and health committee at the plant met monthly. The victim had worked for the paper plant for approximately 15 years and on the baling machine for approximately 2 years. This was the paper plant’s first workplace fatality.

At the time of this fatality, the plant where this incident occurred was preparing for permanent closure. Many employees had already been laid off, and the only production was to deplete existing inventory.

Paper stock is delivered to the plant in different forms, either on large 2000-pound rolls or as precut blank sheet stock packed in boxes that are stacked on pallets. Based on the customer’s order, the paper stock is cut and packed in various dimensions. Stock paper from the rolls or sheets is fed through cutting machines that trim and size the paper product according to the customer’s specific orders. After cutting, the finished product is boxed and ready for shipment to the customer. Waste paper trimmings are collected at each of the cutters by a vacuum system that conveys the paper through a series of overhead ductwork to a 2-stage horizontal paper baler. The baler is in an isolated location at the rear of the facility away from most of the production areas. The termination point for the vacuum system is an approximately 4-foot by 5-foot rectangular, open-front sheet metal box sitting atop the baler feed chute (Figure 2). Paper falls into a feed hopper then down through a 14-foot chute to the baling chamber.

Additionally, waste paper products can be loaded from the front of the baler using a forklift to load the “dumper” with the material to be compressed. When loaded, the operator pushes a button on the side of the dumper (away from the main control panel of the baler) that activates the dumper to raise and dump the material into a lower hopper on the belt conveyor. The belt conveyor carries the material up to the feed chute where it is fed into the hopper and falls down into the baling chamber (Figure 2). Inside the baling chamber, an electronic eye senses the material height and when it reaches a predetermined level, a signal is sent to the baler computer which activates the compressing cycle.

Once the ram is activated, it compresses the material into a bale measuring 30 inches high by 60 inches wide by 80 inches long and weighing approximately 1200 pounds. The bale is secured with wire ties. Once formed, the bale is then pushed out of the baling machine by a second hydraulic ram. As a new bale is formed and pushed from the chamber it is then picked up by a forklift and moved to either storage or shipping.

The compactor/baler involved in this incident could operate in the manual, semi-automatic, or automatic mode. In the manual mode, the ram motion is controlled by the operator. In the semi-automatic mode, an operator initiates compression, after which the machine automatically completes the cycle. In the automatic mode, the machine’s control system senses when the compacting chamber is full and activates the compression cycle.

On the day of the incident, the victim started work at approximately 7 a.m. He was assigned to work at the baler. The victim worked alone compacting, checking wire ties, and moving completed bales to an adjacent storage area. Since the paper flow into the baler was continuous, the baler was normally operated in the automatic mode. Near the end of the shift, at approximately 4 p.m., the shift supervisor indicated that the vacuum system was clogged with paper and that the cutting stations were to temporarily divert their waste trimmings to bins that would later be dumped into the baler. A coworker was walking through the baler area and did not see the victim at his work area, but he did see the baler access door open approximately 6 inches. He went up the stairs to the access door and saw the victim trapped inside the baler. He called out for help, and another employee notified the plant manager. Emergency Medical Services (EMS) was called and responded with a fire department rescue squad within minutes. EMS assessed the victim’s condition and notified the medical examiner, who arrived on site and pronounced the victim dead. Fire department rescuers disconnected the hydraulic lines to the baler and manually pushed the ram back to remove the victim.

Although this incident was unwitnessed, the information collected during this investigation suggests two possible scenarios on how the victim entered the baler’s compression chamber.

On the day of the incident, scrap paper was being fed into the loading chamber of the baler from the overhead duct work. As reported during the investigation, at some point near the end of the shift, incoming paper to the baler was blocked due to jamming. That jamming condition was signaled back up the line, and waste paper was diverted to the bins. The bins were to be later transported by forklift and dumped into the baler. As reported by workers who responded to the victim’s aid, the conveyor was off and the dumper was lowered; however, they were not sure if the baler was off or still in the automatic mode. Access to the loading chamber by climbing up the conveyor belt would have been possible. The victim may have lost his balance and fallen into the baler compression chamber while attempting to free the reported paper jam near the top of the paper discharge chute. The victim was 70 inches tall, and if he had fallen into the baler, he would have been able to reach up to the access door, given that the vertical distance from the bottom of the compression chamber floor to the bottom of the access door is 87 inches. If the victim had reached to the bottom of the access door and pushed it open, power to the hydraulic system would have stopped.

Photographs of the body position inside the compression chamber show that the victim was semi-standing but slumped over against the inside wall of the loading chute. Injuries reported in the autopsy indicate that the victim may have been trying to step up on top of the ram as it started to cycle. Being an experienced baler operator, the victim may have known that the machine was going to cycle and he may have attempted to jump above the ram. The worker who found the victim reported that the access door was open approximately 6 inches. The victim may have reached up in an attempt to open the door knowing that once opened, the safety interlock would stop the ram. He may have succeeded in opening the door enough to activate the safety interlock, causing the ram to stop, but not soon enough to avoid being trapped against the ram and the compression chamber wall. Figure 3 is a graphical representation of the victim’s position inside the baler.

Figure 3. Graphical representation of victim inside baler. Autopsy findings suggest that the victim may have been attempting to step up onto the ram as it cycled.

The access door was equipped with a safety interlock that de-energized power to the baler (Figure 5). The interlock is an electro-magnetic switch that activates when the magnetic field between the switch is broken. When the field is broken, power to the hydraulic pumps of the ram are de-energized. It was reported by the maintenance supervisor that the safety interlock intermittently failed, thereby leaving the ram hydraulic pumps energized. This intermittent problem was observed once before the incident, and once after the incident by both workers and maintenance personnel. Prior to this incident, maintenance moved the contact plates closer together in an attempt to correct the malfunction. It is possible that the victim opened the access door of the baler and relaying that the safety interlock had de-energized the pumps, entered the chamber to clear a jam. If the safety interlock had failed, power would not have been shut down, and once the victim was inside the chamber, the electric eye would have sensed that the chamber was full and started to cycle.

The NIOSH investigators tested the interlocks and could not duplicate the failure. In addition to testing the interlocks, other baler operating features were tested, and the following table outlines the observations noted:

Another item noted during the baler evaluation was the lack of a locking mechanism for hydraulic power on the electric panel. The connection box that the door interlock fed into was easy to unlatch. It was observed that hydraulic pressure held at 2000 psi when electrical power was off only after the ram was past the shear bar and in the baling chamber. Pressure immediately went to zero when the ram was reversed. If the victim were attempting to dislodge a jam with his foot, and the jam were to suddenly be dislodged, it is unlikely that the ram would surge forward and trap the victim because hydraulic fluid is not compressible.

The Medical Examiner listed the cause of death as multiple traumatic injuries due to compression by a baler recycling machine.

Recommendation #1: Employers should ensure that workers are protected from the unexpected movement of machine parts by implementing lockout/tagout procedures (OSHA regulation 29 CFR 1910.147 – Control of Hazardous Energy [lockout/tagout]).

Discussion: Lockout/tagout procedures (OSHA regulation 29 CFR 1910.147 – Control of Hazardous Energy [lockout/tagout]) are designed to protect from the unexpected release of hazardous energy those who must service, inspect, clean, or maintain equipment. Automatically controlled baling machines operate when the control system senses the presence of sufficient material to be compressed. Because the ram motion may not start or may ceased during a jam, workers may not recognize that the machine is still operational and that the ram could activate inadvertently unless the power supply is disconnected and the ram pressure dissipated.

This company had a written lockout/tagout procedure and training, but it was implemented only for the mechanics who service the equipment. A lockout/tagout procedure should be devised for all workers who operate any type of industrial machinery. They should also be trained in the use of these procedures.

Workers should be made aware that before attempting to clear a jammed machine, it must be deactivated, locked out and tagged out so that no other person can reactivate it.

Recommendation #2: Employers should ensure that all safety devices are functioning correctly.

When the safety devices are operating correctly, they protect against the inadvertent exposure of persons to the movement of the ram. The safety interlock on the baling machine involved in this incident had been observed failing twice. It is not known if the interlock failure played a role in this fatality. Although the maintenance foreman said there were two occasions when the electrical power to the hydraulic system was on with the interlocked door open, we were unable to produce this condition. The interlock device did not appear to have been tampered with. The interlock maintained the system in an “off” condition when another metal object was placed near the sensing unit.

Any concerns about of the integrity of the safety features should be addressed immediately and the machine removed from service until proper repairs can be made by a qualified representative authorized by the manufacturer to make such repairs.

Recommendation #3: The employer should establish written operating procedures for machinery that include training in safe operating practices and a safe method for clearing jams.

Discussion: It is unknown if the victim in this incident was clearing a paper jam in the vacuum system that carried paper to the baler or attempting to clear a jam from inside the baler. Training in the safe operation of the baling machine is essential. After conducting a hazard analysis, a written policy should be on the proper operation of the baling machine and procedures for clearing jams both inside the baler and above in the waste paper collection system. All baler employees, as well as maintenance employees, should be instructed in its use.

The American National Standards Institute (ANSI) has developed standards for compactor safety. The ANSI Standard Z245.2 -1992, Stationary Compactors – Safety Requirements, provides guidance in safe design, operation, and maintenance of stationary compactors.

To receive the NIOSH eNews newsletter, enter your email address:

Nancy Romano, M.S. FACE Project Officer Fatality Investigations Team Division of Safety Research NIOSH nioshface@cdc.gov

Cardboard Press Press Inquiries nioshmedia@cdc.gov