Lumispot Tech has established itself as a forefront innovator in the laser technology sector. Leveraging its proprietary development of a new generation of high-uniformity, high-brightness fiber-coupled semiconductor lasers, alongside its precision optical schemes designed in-house, Lumispot Tech has successfully engineered a laser system capable of delivering large field-of-view, high uniformity, and high brightness for sustained operations. Application Scenarios of the Square Light Spot Laser This product line represents Lumispot Tech's independently developed square-spot system, utilizing fiber-coupled semiconductor lasers as the light source. Incorporating high-precision control circuits and conveying the laser through optical fibers into an optical lens, it achieves a square-spot laser output at a fixed divergence angle. Primarily, these products are tailored for the inspection of photovoltaic (PV) cell panels, specifically in the detection of light and dark cells. During the final inspection of cell panel assemblies, Electro-Luminescence (EL) electrical testing and Photo-Luminescence (PL) optical testing are conducted to grade the assemblies based on their luminous efficiency. Traditional linear PL methods fall short in differentiating between light and dark cells. However, with the square-spot system, a non-contact, efficient, and synchronous PL inspection of different areas within the cell assembly is possible. By analyzing the imaged panels, this system facilitates the distinction and selection of light and dark cells, thereby preventing the downgrade of products due to the low luminous efficiency of individual silicon cells. Product Features Performance Characteristics 1. Selectable Performance and High Reliability: The system's output power is customizable, ranging from 25W to 100W to accommodate various PV cell inspection schemes. Its reliability is heightened by the use of single-tube fiber coupling technology. 2. Multiple Control Modes: Offering three control modes, the laser system allows customers to tailor control based on situational needs. 3. High Spot Uniformity: The system ensures stable brightness and high uniformity in its square-spot output, aiding in the identification and selection of anomalous cells. Comparative Analysis Compared to linear array detection, the area camera utilized in the square-spot system allows for simultaneous imaging and detection across the entire effective area of the silicon cell. The uniform square-spot illumination ensures consistent exposure across the cell, enabling clear visualization of any anomalies. Click here for specific datasheet 1. As illustrated in comparative imagery, the square-spot (area PL) method distinctly identifies dark cells that linear PL methods might miss. 2. Moreover, it also enables the detection of concentric circle cells that have progressed to the finished product stage.

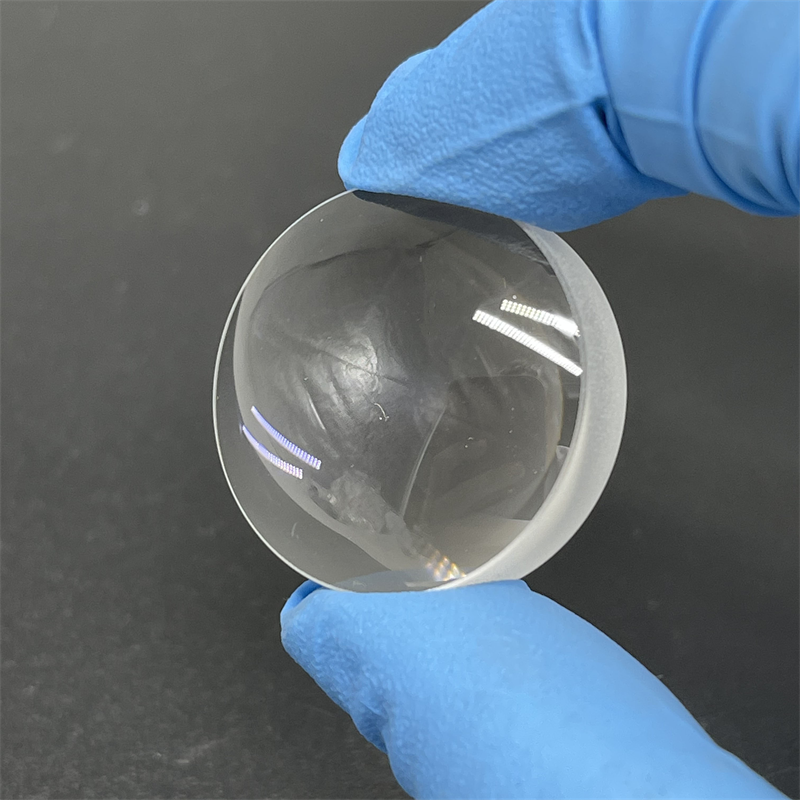

Lumispot Tech has established itself as a forefront innovator in the laser technology sector. Leveraging its proprietary development of a new generation of high-uniformity, high-brightness fiber-coupled semiconductor lasers, alongside its precision optical schemes designed in-house, Lumispot Tech has successfully engineered a laser system capable of delivering large field-of-view, high uniformity, and high brightness for sustained operations. Ge Wedge Prism

This product line represents Lumispot Tech's independently developed square-spot system, utilizing fiber-coupled semiconductor lasers as the light source. Incorporating high-precision control circuits and conveying the laser through optical fibers into an optical lens, it achieves a square-spot laser output at a fixed divergence angle.

Primarily, these products are tailored for the inspection of photovoltaic (PV) cell panels, specifically in the detection of light and dark cells. During the final inspection of cell panel assemblies, Electro-Luminescence (EL) electrical testing and Photo-Luminescence (PL) optical testing are conducted to grade the assemblies based on their luminous efficiency. Traditional linear PL methods fall short in differentiating between light and dark cells. However, with the square-spot system, a non-contact, efficient, and synchronous PL inspection of different areas within the cell assembly is possible. By analyzing the imaged panels, this system facilitates the distinction and selection of light and dark cells, thereby preventing the downgrade of products due to the low luminous efficiency of individual silicon cells.

1. Selectable Performance and High Reliability: The system's output power is customizable, ranging from 25W to 100W to accommodate various PV cell inspection schemes. Its reliability is heightened by the use of single-tube fiber coupling technology. 2. Multiple Control Modes: Offering three control modes, the laser system allows customers to tailor control based on situational needs. 3. High Spot Uniformity: The system ensures stable brightness and high uniformity in its square-spot output, aiding in the identification and selection of anomalous cells.

Compared to linear array detection, the area camera utilized in the square-spot system allows for simultaneous imaging and detection across the entire effective area of the silicon cell. The uniform square-spot illumination ensures consistent exposure across the cell, enabling clear visualization of any anomalies.

Contact Email: sales@lumispot.cn Or leave a message here

Micro Prism For Sale Web Site: https://www.lumispot-tech.com/