Revolutionising Environmental Testing: The Role of Lateral Flow Technology

The laboratory goes green: Learn more about sustainable analyses at anal... In Situ Gas Analyzer

Cambridge Sensotec are experts in gas analysis, producing the Rapidox range of gas analysers for over 17 years. Dynamic and flexible, the company initially specialised in oxygen analysis, however expanded into multiple gases to suit customer requirements and application demands. The Rapidox 1100and Rapidox 2100range of oxygen analysers are particularly suitable for applicationssuch as inert gas blanketing, additive manufacturing, glove boxes, metal heat treatment and research and development projects. There are two types of oxygen sensors used in the Rapidox gas analyse range, these include zirconia and electrochemical, although the majority of the Rapidox gas analysers use a zirconia-based sensor.

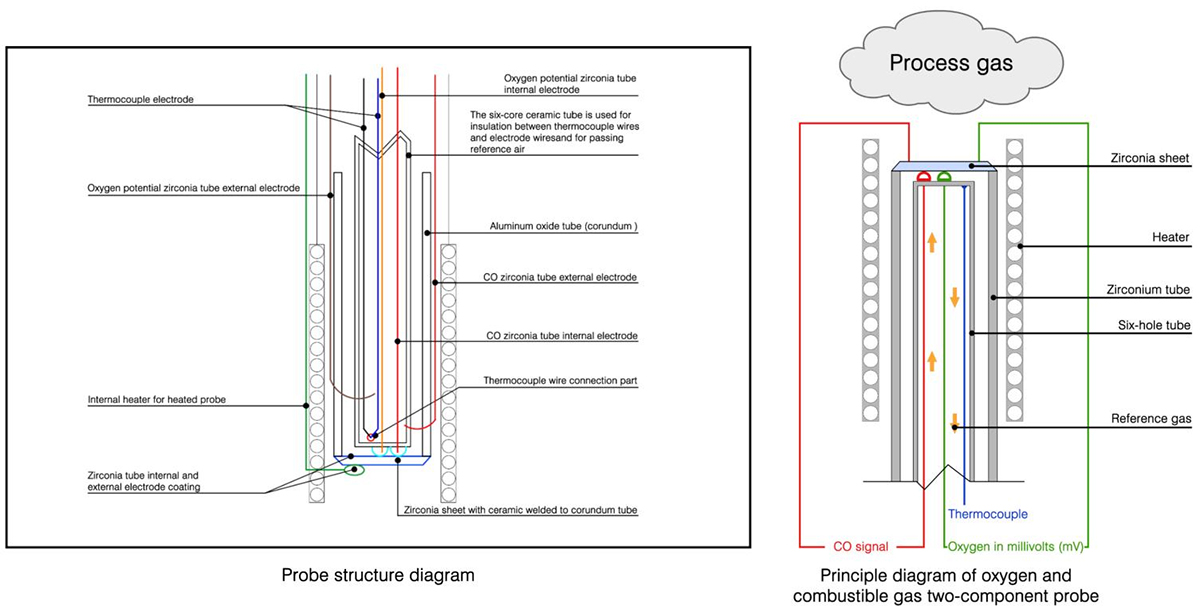

A zirconia oxygen sensor is ideal for the analysis of oxygen within high temperature applications or metal heat treatment, zirconia sensors can also be used to detect vacuum leaks within chambers or glove boxes. The sensor has a very fast response time combined with extremely accurate readings at low oxygen levels, which is suitable for low ppm to 100% gas analysis. In addition, they are robust and have a long lifespan of over thirty-five thousand hours. Typically, the sensors are coated internally and externally with platinum electrodes at temperatures more than 450â°C, the zirconia will begin to conduct oxygen ions by generating a voltage between the electrodes. The value of the voltage is dependant on the differences between the partial pressures of the oxygen in the sample and within the reference gas. Rapidox oxygen analyser interprets this difference to display an oxygen concentration.

However, there are some environments that the zirconia oxygen sensor is not suited, which is why Cambridge Sensotec have developed Rapidox units with electrochemical sensors.

An electrochemical sensor is best suited to applications where explosive gases are present such as hydrocarbons, or where there is a presence of volatile organic gases compounds (VOCs). They also perform well in helium and hydrogen and are suited for use in hazardous areas. Electrochemical sensors are available for oxygen analysis on a scale of either 0.1ppm to 1% or 0-100%. Most of these sensors have two electrodes, a ‘sensing’ and ‘counter’ which are divided by a thin electrolyte coat. When gas enters the sensor there is an oxidisation reaction that is directly proportional to the gas concentration. The Rapidox oxygen analyser interprets this current into an oxygen reading.

For further information on gas analysis, please contact us on +44 (0)1480 462142 or email sales@www.cambridge-sensotec.co.uk.Further details can also be found on our website www.cambridge-sensotec.co.uk.

Envira’s Nanoenvi EQ is a portable air monitoring station featuring sophisticated emission analysers that enable a real time air quality monitoring and fug...

Anybody in the market for purchasing a small sensor air pollution monitoring system will need to consider budgets, but it’s not always obvious how the prod...

At CEM 2023 in Barcelona, Jessica Queron of France's National Institute for the Industrial Environment and Risks (INERIS) introduced the Institute's new guid...

In This Edition Water/Wastewater - Continuous remote water quality monitoring networks Environmental Laboratory - The Important Role of ICP-MS in Understanding the Toxicological Link Be...

Feb 24 2024 San Diego, CA, USA

International Labmate Limited Oak Court Business Centre Sandridge Park, Porters Wood St Albans Hertfordshire AL3 6PH United Kingdom

T +44 (0)1727 858 840 F +44 (0)1727 840 310 E info@envirotech-online.com

Flue Gas Oxygen Analyser Copyright © 2024 Envirotech Online. All rights reserved.