At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

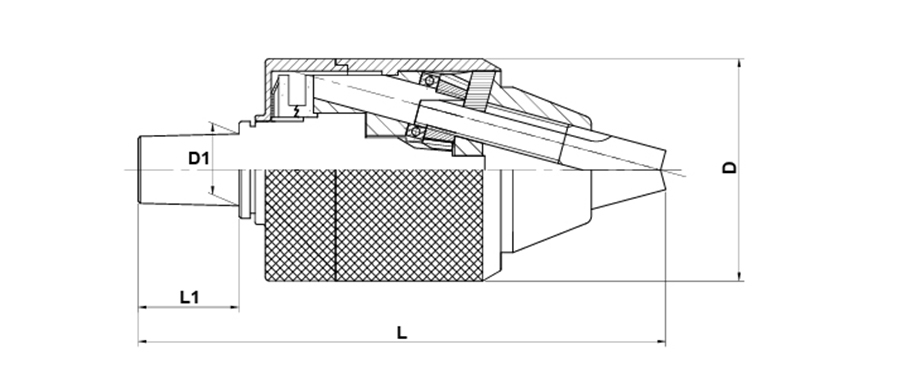

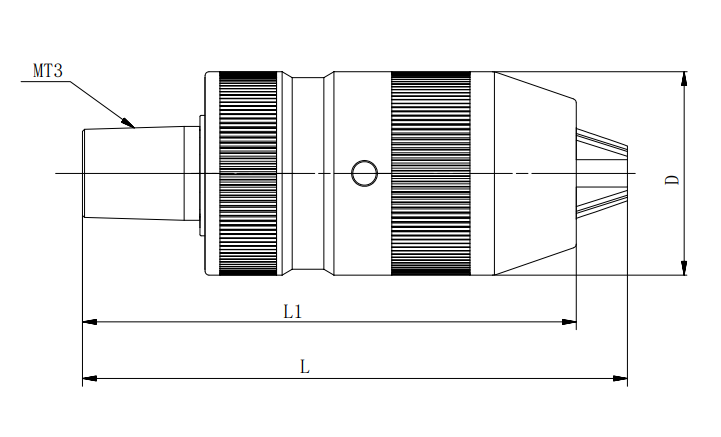

Practical work has served Bridgerland Technical College both in preparing its current students for manufacturing jobs and in appealing to new generations of potential machinists. Chuck Tool

With many machine shops anticipating long-term growth in demand from the semiconductor industry, it is worth the time to heed the advice of manufacturers who have already been servicing this end-market for years.

Decade-long, multiphase automation investments lower operating costs and maintain technology lead in an increasingly competitive global market.

Cumberland Additive’s CNC programmer in Pennsylvania spends most of his time writing programs for machine tools in Texas.

Pairing a shoulder mill with a five-axis machine has cut costs and cycle times for one of TTI Machine’s parts, enabling it to support a niche racing community.

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

With many machine shops anticipating long-term growth in demand from the semiconductor industry, it is worth the time to heed the advice of manufacturers who have already been servicing this end-market for years.

Decade-long, multiphase automation investments lower operating costs and maintain technology lead in an increasingly competitive global market.

Alpha Precision Group (APG) has developed an innovative workholding design for faster spindle speeds through sinter-based additive manufacturing.

Pairing a shoulder mill with a five-axis machine has cut costs and cycle times for one of TTI Machine’s parts, enabling it to support a niche racing community.

A study in repeatable and flexible workholding by one OEM for another.

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

EPTAM Precision Plastics has achieved multiple years of 15% YoY growth by effectively applying Datanomix’s benchmarking and machine monitoring features.

Practical work has served Bridgerland Technical College both in preparing its current students for manufacturing jobs and in appealing to new generations of potential machinists.

Shops need to look at their people, processes and technology to get the most of out their automation systems.

Controlling variability in a closed-loop manufacturing process requires inspection data collected before, during and immediately after machining — and a means to act on that data in real time. Here’s one system that accomplishes this.

Wolfram Manufacturing showcased its new facility, which houses its machine shop along with space for its work as a provider of its own machine monitoring software and as an integrator for Caron Engineering.

Structured light scanning is used to create a digital twin of a manufactured part, but we must understand the measurement reproducibility to best use the data.

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

Verisurf will offer complete metrology solutions that combine its model-based inspection and measurement software, training and live technical support with Hexagon CMMs.

Understanding the differences between measurement methods means their discrepancies can be explained and used as an advantage to produce better correlation.

Zeiss Quality Innovation Days brings together quality and metrology experts from all over the world to take part in industry-specific sessions.

Understanding all the things that contribute to a machine’s full potential accuracy will inform what to prioritize when fine-tuning the machine.

DMG MORI’s Chicago Innovation Days event featured technologies designed to address the difficulties manufacturers face today.

With the help of a 3D vision system and robotic arms from FANUC, MetalQuest was able to automate a physically challenging bin-picking task.

Christopher Clark will provide sales, service and support for the full range of Stäubli customers in North America.

Decade-long, multiphase automation investments lower operating costs and maintain technology lead in an increasingly competitive global market.

Robotic applications are expanding thanks to rubber and silicone-based systems that can handle fragile materials or parts in varying sizes and shapes.

Shops need to look at their people, processes and technology to get the most of out their automation systems.

Across a range of technical presentations aimed at small and mid-sized job shops, the first-ever Automated Shop Conference (TASC) offered insights into several automated technologies, implementation strategies, shopfloor training tips, and even the untapped power of automated coolant delivery.

Automation is no longer a luxury in manufacturing today – it’s a necessity. The Automated Shop Conference (TASC) will connect job shops with experts who offer advice and considerations for this process.

The Automated Shop Conference (TASC) will give shops of all sizes and production volumes key insights and practical guidance on how to implement automation.

Looking to automate your shop floor? The Automated Shop Conference (TASC) will connect shops with experts who can advise them through this transition.

Attend TASC, The Automated Shop Conference, in Novi, Mich on Oct. 11, 2023 for a comprehensive look into how to use automation to transform your machine shop.

Staying adaptable and leading through change for 95 years and counting, Modern Machine Shop celebrates its 95th Anniversary since its first publication in 1928.

The advance toward increasingly automated machining can be seen in the ways tooling, workholding, gaging and integration all support unattended production. This is the area of innovation I found most compelling at the recent International Manufacturing Technology Show.

The renewal of collaborations, partnerships and networking opportunities created a new level of excitement at IMTS 2022 for 86,307 registrants.

Manufacturing has a multi-talented bunch of people, but who knew so many were adept in the facial hair industry? Check out the best of the beards at IMTS!

This year’s show celebrates 10 years of co-location between IMTS and Hannover Messe.

Brent Donaldson of Modern Machine Shop sits down with Supertec's Don Staggenborg to discuss what the IMTS veterans brought to this year's show.

Meet NASA mission system engineer Mike Menzel and learn more about the James Webb Space Telescope at Mitsui Seiki USA’s booth (338700) in the South Hall from 11:00 a.m. to 11:45 a.m. on Thursday, September 15.

When revising part designs, investigate the 3D CAD, the 2D drawing and the part’s functional requirements to determine which details should be tightened up.

Machine tool industry stalwart and friend Barry Rogers will be remembered for his passion, kindness and community spirit. A reflection on Barry’s remarkable career and the impact he had on countless individuals.

Modern electronic height gages are computer-based, touchscreen-operated systems that enable automated measuring routines, error correction and multiple probe offsets, much like a CMM.

These oddities in the way a CNC naturally behaves can help explain some rather unusual situations that may occur during machining.

As part of its commitment to replace its aging submarine fleet, the U.S. Navy is investing heavily in building America’s manufacturing base, including free education and assisting suppliers in modernizing their facilities.

The choice between buying a new machine or refurbishing the current one will become clear after a thorough assessment of the machine.

In the latest episode of our View From My Shop series, MMS Editor-in-Chief Brent Donaldson visited the JN Shapiro Watches headquarters and production facility where Founder Joshua Shapiro—a history teacher turned watchmaker—realized his dream of "making a watch from scratch and everything in it."

Legacy Precision Molds takes us on a tour of their moldbuilding facility. They've recently implemented two automated 5-axis cells for metal and graphite machining that run lights out during nights and weekends.

Take a look inside James Engineering, a high-end CNC Deburring OEM that became a job shop when they decided to produce their own parts in-house.

Tool-holder-spindle-machine combinations each have a unique dynamic response in the same way that each person has a unique fingerprint, which can be revealed using modal testing.

Explore Tech-Max, a CNC machine shop that specializes in precision machining large and complex parts ranging from 10 in. to over 10 ft.

Jrlon, Inc. is recognized as a dependable source and leading supplier of plastic and specialty metal products. They are one of the premier PTFE processors in the United States. Jrlon's expertise also covers a wide range of other performance plastic materials and alloy steels for custom molding, machining, gear manufacturing, technical industrial coatings, welding, and sheet metal fabrication. Driven by innovative designers and engineers, Jrlon manufactures unique products vital to a wide variety of industries.

In this episode of Made in the USA, several executives and senior staff at Hardinge give their first-person account of how they formulated the plan to shift the manufacturing of its milling and turning product lines from its Taiwan plant to its plant in Elmira, New York, the major challenges they encountered and the rewards that made it worth the effort.

The L.S. Starrett Co. has been manufacturing precision measurement tools in Athol, Massachusetts, since 1880. Attention to U.S. manufacturing often focuses on reshoring manufacturing from other countries, but Starrett never left. The facility in Athol employs hundreds and produces thousands of tools that remain vital for measurement in machining and other fields.

The latest episode “Made in the USA” podcast explores a company that uses collaborative robots, one of the key tools helping US machine shops and other manufacturers compete with lower cost countries by automating production.

When Puneet and Neelam Neotia moved from India to the United States several years ago, they brought with them a family background in manufacturing and CNC machining. Now the couple is working to get their startup machine shop off the ground, sourcing new customers and getting the word out about their shop in Clarksville, Indiana. The couple — proud to publicize their "Made in the USA" parts — is leveraging family connections and manufacturing capabilities back in India, but not in the way that some people assume.

Entrepreneur Scott Colosimo found early success in China producing parts for his Cleveland-based motorcycle company in the mid-2000s. This is the story of how IP theft issues overwhelmed the business, prompting Colosimo and his team to start over from scratch — and move production back to the United States.

So far, Made in the USA has looked into system-wide effects of broken supply chains, automation, skilled workforce issues and our perception of manufacturing jobs — examining each topic through a prism of individual experiences. For this final episode for Season 1, let’s look at one more system-wide question and bring it back to personal perspectives: Is there today a new dawn, a new moment for American manufacturing?

The Top Shops 2024 survey for the metalworking market is now live, alongside a new homepage collecting the stories of past Honorees.

To combat the skilled labor shortage, this Top Shops honoree turned to partnerships and unique benefits to attract talented workers.

Doubling sales requires more than just robots. Pro Products’ staff works in tandem with robots, performing inspection and other value-added activities.

From cobots to machine monitoring, this Top Shop honoree shows that machining technology is about more than the machine tool.

Deciding to narrow down its jobs and customers was a turning point for 2023 Top Shops Business Strategies honoree Manda Machine that has led to improvements in the front office and on the shop floor.

Thousands of people visit our Supplier Guide every day to source equipment and materials. Get in front of them with a free company profile.

In the latest episode of our View From My Shop series, MMS Editor-in-Chief Brent Donaldson visited the JN Shapiro Watches headquarters and production facility where Founder Joshua Shapiro—a history teacher turned watchmaker—realized his dream of "making a watch from scratch and everything in it."

Legacy Precision Molds takes us on a tour of their moldbuilding facility. They've recently implemented two automated 5-axis cells for metal and graphite machining that run lights out during nights and weekends.

Take a look inside James Engineering, a high-end CNC Deburring OEM that became a job shop when they decided to produce their own parts in-house.

Tool-holder-spindle-machine combinations each have a unique dynamic response in the same way that each person has a unique fingerprint, which can be revealed using modal testing.

Explore Tech-Max, a CNC machine shop that specializes in precision machining large and complex parts ranging from 10 in. to over 10 ft.

Jrlon, Inc. is recognized as a dependable source and leading supplier of plastic and specialty metal products. They are one of the premier PTFE processors in the United States. Jrlon's expertise also covers a wide range of other performance plastic materials and alloy steels for custom molding, machining, gear manufacturing, technical industrial coatings, welding, and sheet metal fabrication. Driven by innovative designers and engineers, Jrlon manufactures unique products vital to a wide variety of industries.

Ryan Delahanty, Don Hammer, Brian Starnes and Steve Schermann join the company’s leadership team to drive growth and innovation.

IMTS 2024: ANCA celebrates 50 years through the introduction of the MicroX Ultra grinding machine and AIMS Connect software, with live demonstrations.

Kaiser’s ThinBit offerings include over 100,000 precision cutting tools.

IMTS 2024: Mitutoyo America Corp. announces an addition to its linear height gage product line, providing simpler, more repeatable accuracy in measurement.

Hexagon delivers the SmartScan VR800 structured light scanner, providing the flexibility for 3D part inspection via a software-adjustable variable resolution functionality.

Sunnen Products Company receives the President’s “E Star” Award for the furthering of U.S. exports.

One of the hardest steps for most shops moving toward a zero-point system is: where do I begin? I have my machine and I have my application, but how can I effectively add a zero-point system to my machine and speed up my setups? In this webinar, Lang Technovation will discuss how to best approach adding a zero-point system and will share some ideas on how to plan for your best investment. Agenda: What is a zero-point system? Key questions to ask when evaluating best applications How to implement once you have made the decision

Join Hexagon to learn how you can transcend traditional CAM systems to revolutionize your discrete part programming. Hexagon's comprehensive approach integrates design, manufacturing and inspection processes to streamline production workflows and achieve operational excellence. Discover how its advanced suite of CAD/CAM, process optimization and automation technologies empowers manufacturers — from medical to aerospace — to seamlessly transition from prototyping to full-scale production. This session is designed for professionals seeking to enhance precision, efficiency and quality in CNC machining operations, providing valuable insights into the latest advancements in manufacturing technology. Agenda: Optimizing part preparation for error-free manufacturing Simplifying complex part machining through advanced CNC programming Enhancing safety and efficiency with collision avoidance and process verification Leveraging shop-floor production intelligence with automated machine monitoring Driving manufacturing success through effective automation and collaboration

First article inspection (FAI) creation is an essential element of quality control programs but can consume a significant amount of time. In this webinar, Rebecca Keller will discuss a tool that consolidates all requirements into an accountability checklist, keeping drawing and inspection sheets in sync. Automatically capture sheet and zone and identify bill of materials (BOM) and specifications for a complete and accurate report. This software exports a professional ballooned print as a PDF and can output to your customized Excel spreadsheet. In this session, Discus Software will go over how to reduce quality escapes that occur from overlooking requirements. Failing results are flagged in real time and any missing FAIR AS9102 data is also flagged for compliance to the standard. Easily renumber balloon sequencing and change between imperial and metric unites as required by your customers. Learn how to seamlessly import your coordinate-measuring machine (CMM) data to validate each result and easily flag non-conformances. Use any CMM in your shop to create result data and automatically populate the designed tooling. The tool to discuss will assist you in keeping up with the growing prevalence of 3D modeling in manufacturing. Using the product manufacturing information (PMI) of the model, this software extracts the geometry and notes from the model to create views with ballooned data and exports to the inspection sheet. Agenda: Error-proof each FAI for accuracy and customer approval Eliminate the need for manual data entry Use your CMM output to populate FAI actuals Address your customer's requirement for model-based definition (MBD)

In a rapidly-evolving manufacturing landscape, the integration of additive manufacturing (AM) technologies into CNC machining operations is not just an innovation but a necessity for staying competitive. Phillips Corporation invites you to this insightful webinar that sheds light on the transformative impact of 3D printing in CNC shops. Join the presenters as they delve into real-world applications, financial insights and the future of manufacturing. Join Phillips for this engaging webinar on how 3D printing can revolutionize your CNC operations from enhancing design flexibility and operational efficiency to securing significant financial advantages. Whether you’re just starting to explore the potential of additive manufacturing or looking to optimize its integration, this session will provide valuable insights and practical advice for leveraging AM technology to its fullest potential. Agenda: Learn how AM streamlines production processes. drastically reducing lead times and the need for extensive inventory while optimizing labor costs Explore the design flexibility that AM offers, allowing for complex geometries and customization options not feasible with traditional CNC machining Review the compelling financial rationale for integrating AM now, detailing cost savings, efficiency improvements and the competitive edge it provides

See how combining metrology and microscopy technologies can increase efficiency and reduce costs. The growing demand for miniaturization and high-density interconnects make it increasingly difficult to identify defects, meaning a need for inspection technology that can do traditional metrology applications and optical inspection tasks in microscopy. Printed circuit boards (PCB) and printed circuit assemblies (PCA) need advanced metrology and inspection systems to build high reliability devices that are important for new energy vehicles (NEV), aerospace, spacecraft and medical device creation. Both metrology and microscopy technologies combine to fulfill high-end geometric dimensioning and tolerancing (GD&T) tasks along with image analysis techniques required for new product development and failure analysis inspection. This trend helps manufacturers increase efficiency while saving on service costs and space. Agenda: Understand how trends in electronics and medical manufacturing affect quality assurance Learn how microscopy inspection and metrology work together to support electronics manufacturing Application experts offer inspection tips and example workflows Understand savings made on service costs and space

Learn about the benefits of using fully integrated CAD and CAM software and the automation tools available. Agenda: Learn how to start using the CAM software included with SolidWorks See how a fully integrated CAD/CAM system saves significant amounts of programming time Watch presentations of the automation tools available Gather information on the levels of fully integrated CAD/CAM to fit your machining needs Gain an understanding of how other machine shops have benefitted by using a fully integrated system

RAPID + TCT is returning to the west coast after a decade away! For more than 30 years, RAPID + TCT has defined the crucial role of additive manufacturing and empowered the establishment of an industry that continues to conceive, test, improve and manufacture new products at a faster, more cost-efficient pace. SME and Rapid News Publications have teamed up to produce the annual RAPID + TCT event, which takes place June 25-27 in Los Angeles, California. The event is for those who provide technology and for those who need to understand, explore and adopt 3D printing, additive manufacturing, 3D scanning, CAD/CAE, metrology and inspection technologies.

Laser powder bed fusion is the most widely used additive manufacturing method for metal part production, and electron beam melting is a closely related technology. For metalworking facilities contemplating a move into metal AM using technologies such as these, here is a road map for success. Speakers will cover materials, safety, part design, production workflow and differences between laser and electron beam metal powder bed fusion systems.

FABTECH 2024 will be held October 15-17, 2024, in Orlando, Florida, at the Orange County Convention Center. FABTECH provides a convenient ‘one-stop shop’ venue where you can meet with world-class suppliers, discover innovative solutions, and find the tools to improve productivity and increase profits. There is no better opportunity to network, share knowledge and explore the latest technology, all here in one place. Future U.S. Show Dates and Locations 2025 – September 8-11 at McCormick Place in Chicago, IL 2026 – October 21-23 at Las Vegas Convention Center in Las Vegas, NV 2027 – September 13-16 at McCormick Place in Chicago, IL

Formnext Chicago is an industrial additive manufacturing expo taking place April 8-10, 2025 at McCormick Place in Chicago, Illinois. Formnext Chicago is the second in a series of Formnext events in the U.S. being produced by Mesago Messe Frankfurt, AMT – The Association For Manufacturing Technology, and Gardner Business Media (our publisher).

When revising part designs, investigate the 3D CAD, the 2D drawing and the part’s functional requirements to determine which details should be tightened up.

The choice between buying a new machine or refurbishing the current one will become clear after a thorough assessment of the machine.

Understanding all the things that contribute to a machine’s full potential accuracy will inform what to prioritize when fine-tuning the machine.

While there are many changes to adopt when moving to five-axis, they all compliment the overall goal of better parts through less operations.

Consider what types of implementation your shop prefers when deciding between workpiece-handling and pallet-handling automation solutions.

When getting a grip on stainless steel, make sure you are very specific in how you talk about it and understand the pertinent information you need.

Alpha Precision Group (APG) has developed an innovative workholding design for faster spindle speeds through sinter-based additive manufacturing.

The chuck jaws used in this turning operation were previously machined, but carried more weight and clamped with more pressure than necessary. Now, APG’s sister company uses 3D printed jaws more optimized to this process.

When Alpha Precision Group (APG) of Ridgway, Pennsylvania, added its first metal 3D printer in 2018, its dual aims were to experiment with this technology as a means of iterating parts destined for metal injection molding (MIM) and to be able to create more durable workholding fixtures for CNC machining.

One of the first applications the company found for metal 3D printing has proven to be a valuable business opportunity, both for serving internal needs of its sister machining business and now, those of outside customers as well.

APG has developed a chuck jaw workholding assembly for turning cam gears that it now 3D prints as an alternative to a legacy solution. It has since patented the design and is currently offering 3D printed chuck jaws for sale to external users as well.

APG’s sister company utilizes the 3D printed chuck jaws in a turning process on a DMG MORI lathe tended by a FANUC robot.

The original workholding solution for these cam gears consisted of legacy jaws machined from mild steel. While effective, the chuck jaws were heavier than they needed to be, weighing 2,100 grams in total. More clamping pressure was therefore needed to offset the potential reduction in clamp force due to centrifugal force created as the chuck and part spin during the turning operation. These conventional jaws often clamped the gear so tightly that it deformed the part and interrupted its circularity.

Using its first metal 3D printer, a Studio system for bound metal deposition (BMD) from Desktop Metal, APG embarked on a redesign aimed at lightweighting the chuck jaws.

Bound metal deposition applies polymer filament carrying metal powder to build up green metal forms, similar to any desktop fused filament fabrication (FFF) printer printing in polymer. To arrive at fully metal parts, however, the BMD prints must be debound and then sintered. Some shrinkage happens during this step which has to be accounted for in the design, similar to MIM. Bound metal deposition offers an accessible way of 3D printing in metals due to its lower cost and reduced safety concerns compared to other methods. It also provides more geometric freedom than machining, which was critical to this application.

APG was able to reduce the amount of material in the chuck jaws by using lattice structures inside the forms, and by bridging between features rather than building solid walls. This chuck jaw redesign resulted in a lighter workholding solution, allowing for clamping pressure to be reduced from 30 to 15 psi, mitigating the deformation challenge.

APG first 3D printed the chuck jaws using its Studio system from Desktop Metal (on the table to the right). The company was able to further optimize the design and produce the jaws more quickly by adapting them for production on the Dominant Moldjet system from Tritone Technologies (left).

APG took this concept further when it acquired its Dominant 3D printer, a machine from Tritone Technologies that uses a proprietary 3D printing process called Moldjet. Rather than building the geometry directly, the Dominant machine 3D prints wax molds that are then filled with a metal paste material. Each layer is dried and inspected before the next mold is printed and construction continues. Following printing, the wax is melted away from the build before parts are removed from the machine to be sintered. The process is highly productive, with up to six build trays running at once inside the carousel system. Further, the process — with the mold that is built as the part is built — enables even more complex geometries than deposition-style 3D printing, which APG was able to leverage to develop an even more complex and efficient design.

APG iterated the chuck jaws again, this time optimizing them for manufacturing with Moldjet and further reducing the material used. The Moldjet version of the chuck jaws weigh just 492 grams, a weight reduction of nearly 77% compared to the original. This new design saves material in the manufacturing of the jaws, and actually aids productivity, because it allows the turning operation to run at a faster spindle speed.

Cycle time impact is not large for APG’s cam turning application, the company says, because the brief cut on this part makes acceleration and deceleration the more important factor. But a promise the company sees for customers of the chuck is higher sustained spindle speed without clamping force reduction.

The Moldjet-produced chuck jaws are 77% lighter than the original machined solution and prevent deformation on the part with reduced clamping pressure.

Learn more about how Alpha Precision Group uses BMD, Moldjet and binder jetting in tandem with conventional metal injection molding (MIM) and other technologies in this article.

See how the Moldjet process works and other applications APG is finding for this technology in this video, shot on-site at the company’s Ridgway facility.

Stephanie Hendrixson reports on 3D printing technology and applications as executive editor of Additive Manufacturing Media. She contributes to Additive Manufacturing magazine and The BuildUp newsletter, and appears on the AM Radio podcast and The Cool Parts Show. SUBSCRIBE HERE.

VersaBuilt’s automation systems significantly boosted Innovative Fabrication’s revenue. In return, the shop has helped VersaBuilt optimize its products.

Decade-long, multiphase automation investments lower operating costs and maintain technology lead in an increasingly competitive global market.

When a casting proved too malleable for traditional gripping, Thomas/Euclid Industries adopted — and succeeded with — Blue Photon adhesive workholding.

Automotive dies and die inserts are often complex, one-off parts with little room for error. Integrity Tool's investments in modular workholding tools and 3D optical scanning have allowed the company to create niche capabilities for its CNC machined parts.

The Desktop Metal Studio System demonstrates time and cost savings in prototyping and improving the parts for Lumenium’s IDAR engine.

Both metal 3D printing processes are ready for production, but which wins out for speed and cost? Research from The Barnes Global Advisors offers a case study.

Forget “additive versus subtractive.” Machining and metal additive manufacturing are interconnected, and enhance the possibilities for one another. Here is a look at just some of the ways additive and machining interrelate right now.

Machine Power Tool Modern Machine Shop is the leading publication and media brand in North America devoted to CNC machining. MMS combines unprecedented editorial access to manufacturing facilities with decades of experience to provide long-form content that is both insightful and impactful. About Us