Register for features like favorites, compare, comprehensive advice.

Login to retrieve your previously saved properties and more 18mm Ply

By continuing, you agree to Timesproperty’ T&C & Privacy Policy

Simplify your home buying journey with Times Property. Connect with an expert today!

I agree to Timesproperty.com T&C & Privacy Policy

Waterproof plywood is a type of wood specially treated to resist water damage, making it ideal for construction projects where moisture resistance is essential. Its durability and reliability make it a popular choice in various applications. In this guide, we'll delve into the different aspects of waterproof plywood, exploring its types, benefits, common uses, and safety precautions in simpler terms. Understanding Waterproof Plywood

Waterproof plywood, a form of engineered wood, undergoes specialised treatment to withstand water damage effectively. Unlike conventional plywood, this water-resistant variant incorporates a unique adhesive, rendering it resistant to water penetration, mould, and mildew growth. Thatched Roof: Meaning And Design Ideas For Sustainable Living Introduction To Thatched Roof Designs Do you want to add a little bit of history to your house? Think about how charming a thatched roof is! Made from basic elements like straw, dry grass, and other environmentally acceptable resources, this roofing design not only improves the look of your home but also encourages sustainability. Its rustic cha...

Introduction To Thatched Roof Designs Do you want to add a little bit of history to your house? Think about how charming a thatched roof is! Made from basic elements like straw, dry grass, and other environmentally acceptable resources, this roofing design not only improves the look of your home but also encourages sustainability. Its rustic cha...

Typically crafted from multiple layers of wood veneer bonded together with the waterproofing adhesive, the strength and durability of waterproof plywood increase with the number of layers used in its construction. Additionally, these plywood sheets are engineered to maintain their structural integrity even when exposed to moisture, making them highly suitable for a variety of applications in both indoor and outdoor settings. Types Of Waterproof Plywood In India

There are several types of waterproof plywood available in India, each with its own unique properties and price range. Here's a breakdown of some popular options:

1. Commercial Plywood (MR Grade): Price: Rs 35 - Rs 100 per square foot (approx.) Features: Moderately water-resistant, suitable for indoor applications with occasional moisture exposure. Made with melamine resin glue. Common uses: Furniture, cabinets, shelves, partitions.

Price: Rs 35 - Rs 100 per square foot (approx.)

Features: Moderately water-resistant, suitable for indoor applications with occasional moisture exposure. Made with melamine resin glue.

Common uses: Furniture, cabinets, shelves, partitions.

2. Boiling Water Proof (BWP) Plywood: Price: Rs 100 - Rs 200 per square foot (approx.) Features: Highly water-resistant, can withstand boiling water for short durations. Made with phenol-formaldehyde resin glue. Common uses: Kitchens, bathrooms, laundry rooms, outdoor furniture.

Price: Rs 100 - Rs 200 per square foot (approx.)

Features: Highly water-resistant, can withstand boiling water for short durations. Made with phenol-formaldehyde resin glue.

Common uses: Kitchens, bathrooms, laundry rooms, outdoor furniture.

3. Marine Grade Plywood: Price: Rs 200 - Rs 300 per square foot (approx.) Features: Completely waterproof, can withstand prolonged exposure to water and harsh weather conditions. Made with high-quality waterproof glues and treated wood. Common uses: Boats, marine structures, outdoor signage, swimming pools.

Price: Rs 200 - Rs 300 per square foot (approx.)

Features: Completely waterproof, can withstand prolonged exposure to water and harsh weather conditions. Made with high-quality waterproof glues and treated wood.

Common uses: Boats, marine structures, outdoor signage, swimming pools.

4. Film Faced Plywood (FFR): Price: Rs 150 - Rs 250 per square foot (approx.) Features: Highly durable, waterproof, and resistant to chemicals and abrasion. Has a phenolic film coating on both sides. Common uses: Concrete shuttering, construction, industrial applications.

Price: Rs 150 - Rs 250 per square foot (approx.)

Features: Highly durable, waterproof, and resistant to chemicals and abrasion. Has a phenolic film coating on both sides.

Common uses: Concrete shuttering, construction, industrial applications.

5. Blockboard: Price: Rs 50 - Rs 150 per square foot (approx.) Features: Moderately water-resistant, made with a core of wooden strips sandwiched between veneer layers. Common uses: Furniture, doors, partitions, panelling. Advantages And Disadvantages Of Waterproof Plywood Advantages Disadvantages Resistant to water damage Higher initial cost Long-lasting and durable Limited availability in certain areas Suitable for both indoor and outdoor applications Can be heavier than regular plywood Provides a stable and sturdy base for construction Requires proper installation and maintenance Resistant to mould, mildew, and rotting May contain chemicals in pressure-treated variants Offers versatility in design and application Cutting and shaping can be more challenging Enhances the lifespan of structures in moisture-prone environments Variability in quality depending on the manufacturing process Can withstand harsh weather conditions May have limited colour or finish options Applications Of Waterproof Plywood

Price: Rs 50 - Rs 150 per square foot (approx.)

Features: Moderately water-resistant, made with a core of wooden strips sandwiched between veneer layers.

Common uses: Furniture, doors, partitions, panelling.

Limited availability in certain areas

Suitable for both indoor and outdoor applications

Can be heavier than regular plywood

Provides a stable and sturdy base for construction

Requires proper installation and maintenance

Resistant to mould, mildew, and rotting

May contain chemicals in pressure-treated variants

Offers versatility in design and application

Cutting and shaping can be more challenging

Enhances the lifespan of structures in moisture-prone environments

Variability in quality depending on the manufacturing process

Can withstand harsh weather conditions

May have limited colour or finish options

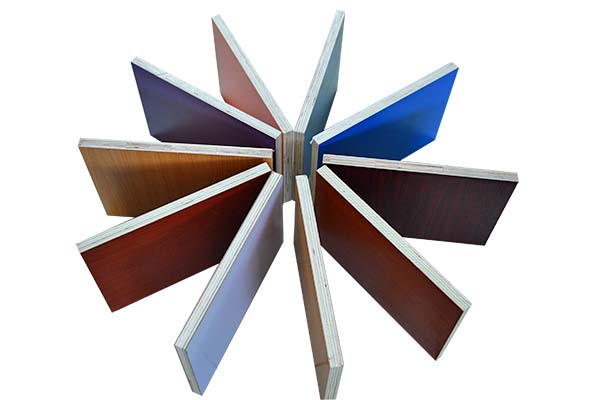

Image Source: iStock Construction: Waterproof plywood finds extensive use in construction projects for various structural elements such as walls, floors, roofs, and formwork. Its resistance to moisture makes it suitable for both indoor and outdoor applications. Marine: Due to its ability to withstand water damage, marine plywood is widely used in boat building, yacht construction, and other marine applications. It provides a durable and reliable material for hulls, decks, bulkheads, and cabinetry in watercraft. Furniture Making: Waterproof plywood is utilised in the manufacture of outdoor furniture pieces such as tables, chairs, benches, and loungers. It ensures that the furniture remains robust and long-lasting, even when exposed to rain or moisture. Exterior Structures: Waterproof plywood is commonly employed in the construction of exterior structures like sheds, gazebos, pergolas, and playhouses. It serves as a sturdy and weather-resistant material for siding, roofing, and decking in these outdoor spaces. Flooring: In areas prone to moisture, such as bathrooms, kitchens, and basements, waterproof plywood is used as a subflooring material beneath tiles, vinyl, or laminate flooring. It provides a stable and moisture-resistant base, preventing damage to the flooring above. Decorative Panels: Waterproof plywood with decorative finishes or laminates is utilised in interior design applications for wall panelling, cabinetry, and shelving. Its water resistance ensures longevity and durability in areas susceptible to moisture exposure, such as kitchens and bathrooms. Landscaping: Pressure-treated waterproof plywood is employed in landscaping projects for constructing retaining walls, raised garden beds, and outdoor seating. It withstands exposure to soil moisture and weather elements, prolonging the lifespan of landscaping structures. Concrete Formwork: Film-faced plywood is extensively used as formwork in concrete construction projects. Its smooth surface and water-resistant coating facilitate easy formwork removal, resulting in high-quality concrete finishes for walls, columns, and slabs. Installation And Maintenance Tips

Construction: Waterproof plywood finds extensive use in construction projects for various structural elements such as walls, floors, roofs, and formwork. Its resistance to moisture makes it suitable for both indoor and outdoor applications.

Marine: Due to its ability to withstand water damage, marine plywood is widely used in boat building, yacht construction, and other marine applications. It provides a durable and reliable material for hulls, decks, bulkheads, and cabinetry in watercraft.

Furniture Making: Waterproof plywood is utilised in the manufacture of outdoor furniture pieces such as tables, chairs, benches, and loungers. It ensures that the furniture remains robust and long-lasting, even when exposed to rain or moisture.

Exterior Structures: Waterproof plywood is commonly employed in the construction of exterior structures like sheds, gazebos, pergolas, and playhouses. It serves as a sturdy and weather-resistant material for siding, roofing, and decking in these outdoor spaces.

Flooring: In areas prone to moisture, such as bathrooms, kitchens, and basements, waterproof plywood is used as a subflooring material beneath tiles, vinyl, or laminate flooring. It provides a stable and moisture-resistant base, preventing damage to the flooring above.

Decorative Panels: Waterproof plywood with decorative finishes or laminates is utilised in interior design applications for wall panelling, cabinetry, and shelving. Its water resistance ensures longevity and durability in areas susceptible to moisture exposure, such as kitchens and bathrooms.

Landscaping: Pressure-treated waterproof plywood is employed in landscaping projects for constructing retaining walls, raised garden beds, and outdoor seating. It withstands exposure to soil moisture and weather elements, prolonging the lifespan of landscaping structures.

Concrete Formwork: Film-faced plywood is extensively used as formwork in concrete construction projects. Its smooth surface and water-resistant coating facilitate easy formwork removal, resulting in high-quality concrete finishes for walls, columns, and slabs.

Image Source: iStock Proper Sealing: Ensure all edges and surfaces of waterproof plywood are adequately sealed with appropriate waterproofing products to prevent moisture ingress and enhance longevity. Correct Fastening: Use corrosion-resistant fasteners, such as stainless steel screws or nails, to secure waterproof plywood during installation. Avoid overdriving fasteners to prevent damage to the plywood surface. Gap Management: Leave small gaps between plywood sheets during installation to accommodate natural expansion and contraction due to changes in temperature and humidity. Fill gaps with a flexible sealant to prevent water infiltration. Regular Inspection: Periodically inspect waterproof plywood surfaces for signs of damage, such as cracks, delamination, or water stains. Promptly repair any issues to prevent further deterioration. Cleaning and Maintenance: Clean waterproof plywood surfaces regularly using a mild detergent solution and a soft brush or cloth. Avoid harsh chemicals or abrasive cleaners that may damage the waterproofing treatment. Safety Precautions

Proper Sealing: Ensure all edges and surfaces of waterproof plywood are adequately sealed with appropriate waterproofing products to prevent moisture ingress and enhance longevity.

Correct Fastening: Use corrosion-resistant fasteners, such as stainless steel screws or nails, to secure waterproof plywood during installation. Avoid overdriving fasteners to prevent damage to the plywood surface.

Gap Management: Leave small gaps between plywood sheets during installation to accommodate natural expansion and contraction due to changes in temperature and humidity. Fill gaps with a flexible sealant to prevent water infiltration.

Regular Inspection: Periodically inspect waterproof plywood surfaces for signs of damage, such as cracks, delamination, or water stains. Promptly repair any issues to prevent further deterioration.

Cleaning and Maintenance: Clean waterproof plywood surfaces regularly using a mild detergent solution and a soft brush or cloth. Avoid harsh chemicals or abrasive cleaners that may damage the waterproofing treatment.

Image Source: iStock Personal Protective Equipment (PPE): Wear appropriate PPE, including safety glasses, gloves, and a dust mask, when cutting, sanding, or handling waterproof plywood to protect against dust, splinters, and chemical exposure. Ventilation: Ensure adequate ventilation in the work area to dissipate dust and fumes generated during cutting or sanding operations. Work in well-ventilated spaces or use dust extraction systems to minimise inhalation hazards. Tool Safety: Use sharp, properly maintained tools and equipment when working with waterproof plywood to minimise the risk of accidents or injuries. Follow manufacturer guidelines and safety instructions for all power tools. Handling Precautions: Lift and carry waterproof plywood sheets with care to prevent strain or injury. Avoid bending or flexing the plywood excessively, as this can cause damage to the material and compromise its waterproofing properties. Chemical Exposure: Exercise caution when working with pressure-treated waterproof plywood, as it may contain chemicals that can be harmful if ingested or inhaled. Follow safety data sheets and manufacturer recommendations for handling and disposal. Guidelines For Selecting Suitable Waterproof Plywood

Personal Protective Equipment (PPE): Wear appropriate PPE, including safety glasses, gloves, and a dust mask, when cutting, sanding, or handling waterproof plywood to protect against dust, splinters, and chemical exposure.

Ventilation: Ensure adequate ventilation in the work area to dissipate dust and fumes generated during cutting or sanding operations. Work in well-ventilated spaces or use dust extraction systems to minimise inhalation hazards.

Tool Safety: Use sharp, properly maintained tools and equipment when working with waterproof plywood to minimise the risk of accidents or injuries. Follow manufacturer guidelines and safety instructions for all power tools.

Handling Precautions: Lift and carry waterproof plywood sheets with care to prevent strain or injury. Avoid bending or flexing the plywood excessively, as this can cause damage to the material and compromise its waterproofing properties.

Chemical Exposure: Exercise caution when working with pressure-treated waterproof plywood, as it may contain chemicals that can be harmful if ingested or inhaled. Follow safety data sheets and manufacturer recommendations for handling and disposal.

When faced with the task of choosing the most appropriate waterproof plywood for your interior design endeavours, several critical factors merit consideration. Among the array of plywood types tailored for home interiors, namely BWR (boiling water resistant), MR (moisture resistant), and BWP (boiling water proof), discerning the right fit is paramount.

When uncertain, seeking advice from an interior specialist can aid in identifying the optimal waterproof plywood type tailored to your home's requirements. Additional specifications to assess include:

Opt for plywood boasting a high degree of moisture resistance, gauged by its capacity to endure water exposure without succumbing to warping or delamination. Premium waterproof plywood typically exhibits a moisture content below five percent.

The grade of waterproof plywood serves as a gauge for assessing bonding strength, overall quality, and durability. Grade A variants boast a refined, sanded texture, often employed in furniture crafting. Grades B and C may feature minor imperfections, while Grade D, the most economical option, tends to compromise durability for affordability.

Thicker plywood offerings afford heightened strength and stability. Interior projects typically suffice with two to three-millimetre plywood, whereas outdoor endeavours may necessitate a five-ply, four-millimetre thickness. For roofing or enduring structures, a seven-layered, multi-ply configuration is commonly preferred.

Verify that selected plywood exhibits resistance to termite infestation, as these pests pose a substantial threat to furniture and fixtures. Plywood treated with anti-termite solutions offers robust protection against such infestations.

Balancing quality with affordability necessitates prudent consideration of plywood costs. While prioritising high-quality options remains imperative, aligning with budget constraints is equally crucial. Conducting price comparisons among various suppliers facilitates identifying a suitable equilibrium between quality and cost-effectiveness.

Furthermore, augmenting conventional plywood into waterproof variants is viable through the application of waterproof furniture paints, varnishes, epoxy resin coatings, waterproofing membranes, or sealants. Nevertheless, consulting with an interior specialist prior to waterproof plywood selection is recommended for informed decision-making and optimal outcomes.

Yes, waterproof plywood is suitable for outdoor furniture in various climates, including regions with extreme weather conditions. Its resistance to moisture, mould, and mildew makes it an ideal choice for withstanding the elements and maintaining durability over time.

Waterproof plywood is commonly used in DIY projects like constructing raised garden beds. Its resistance to moisture and rot makes it an excellent choice for outdoor applications, providing a sturdy and long-lasting structure for growing plants.

All About NVSP Portal 2024: Change Your Voter ID Address On The National Voters Services Portal

The National Voters' Service Portal (NVSP) is an online platform created by the Election Commission of India (ECI) to assist and empower voters. It simplifies the electoral process by providing a

Online Puducherry Electricity Bill Payments And Additional Services

Paying your electricity bill in Puducherry has become easier with online portals. No more waiting in lines or searching for cash. This portal doesn't just handle bill payments, it offers various s

UPPCL Electricity Bills: A Guide To Payments, Bill Viewing, And Complaints

Introduction To UPPCL Electricity Bills The task of transmitting electricity to millions of households and businesses across the state falls largely into the hands of Uttar Pradesh Power Corporatio

Red Oxide Flooring In Modern Home Design: Advantages. Maintenance And More

Introduction To Red Oxide Flooring In the realm of interior design, the allure of traditional materials often competes with the sleekness of modern aesthetics. Among these timeless materials, red o

Online Water Bill Payment In Odisha

Introduction To Online Water Bill Payment In Odisha, residents can conveniently manage their water-related affairs through user-friendly online portals. For those seeking a new water connection, th

Plywood Laminate Sheet OTP is sent to Your Mobile Number