© 2024 Power Automedia. All rights reserved.

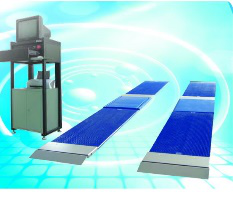

Superflow is a name well-recognized in the performance automotive aftermarket for its range of dynamometers and flowbenches that cater to both the tuning side of things, as well as the engine builder. Here at SEMA 2015, its two-wheel drive Maximum Capacity chassis dyno was on display. With two, large, air-cooled, Eddy current brakes that provide 1,600 horsepower of power absorption, it can withstand 200 mph wheel speeds, giving customers a lot of ceiling to work with in tuning vehicles. Brake Equipment

It’s phenomenal in high-torque or long-testing duration applications, where they’re developing a product and need to test for hours on end. – Travis Thirkettle, Superflow“It’s phenomenal in high-torque or long-testing duration applications, where they’re developing a product and need to test for hours on end. With this unit, customers can test continuously,” says Superflow’s Travis Thirkettle.

It’s phenomenal in high-torque or long-testing duration applications, where they’re developing a product and need to test for hours on end. – Travis Thirkettle, Superflow

Superflow includes its WinDyne data acquisition and control software, which is standard on all of its products, including their engine dynamometers. “Engine dyno operators who are familiar with the software can transition into the chassis dyno relatively easily, and it affords the opportunity to instrument the chassis dyno as much as we do an engine dyno by using the same sensors and flow turbines,” says Thirkettle. “The software has a lot of configurations, so you can use it to test many different applications.”

Super flow also boasts all-wheel drive chassis dynos that pair a set of rollers linked mechanically with a driveshaft. Thirkettle explains this keeps the rollers in-tune with one another and operating at the same speed. Super flow calls this Mechanical Roll Synchronization … it differs from the belt-drive systems used in some other chassis dynos that are prone to breakage, parasitic losses, and other factors.

The Superflow chassis dynos future a push-button wheelbase adjustment, trunnion-mounted differentials (allows a load cell to be put on a front and rear rollset and deliver power output individually or in a sum with an all-wheel drive car ), Eddy current absorption capabilities, a large tire contract patch, mechanical all-wheel drive synchronization, and road simulation technology.

Build your own custom newsletter with the content you love from Dragzine, directly to your inbox, absolutely FREE!

© 2024 Power Automedia. All rights reserved.

We will safeguard your e-mail and only send content you request.

We'll send you the most interesting Dragzine articles, news, car features, and videos every week.

We promise not to use your email address for anything but exclusive updates from the Power Automedia Network.

We will safeguard your e-mail and only send content you request.

Thank you for your subscription.

We think you might like...

We think you might like...

Truck Brake Tester Thank you for your subscription.