Cubility’s MudCube shale shaker made a name for itself on its first commercial installation on Maersk Drilling’s Maersk Giant in the North Sea.

The North Sea has long been a critical area of exploration and production within the oil and gas industry. Advances in technology mean many fields once thought to be fully tapped are still producing at great volumes. The region is also known for its stringent HSE (health, safety and environment) standards, particularly related to waste and employee conditions. One area of concern is the waste produced and environments created during the solids-control process, where fluids and cuttings are separated via a shaker. Composite Frame 1165x585mm

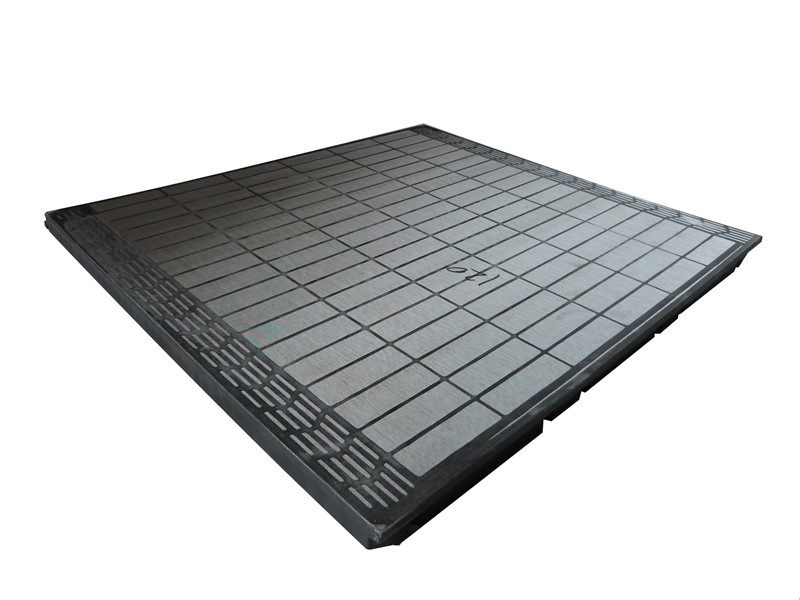

Traditional shale shakers, which rely on technologies created in the 1930s, have remained the primary method for solids control for both on- and offshore wells. Despite incremental improvements over the years, the traditional shale shaker still poses a number of HSE concerns, including noise, vibration, emissions, and inefficient solids control. MaerskDrillingrecently decided to tackle the HSE and inefficiency issues, created by traditional shale shakers, by using Cubility’s MudCube on its Maersk Giant jackup rig. Its use aboard the jackup was the first commercial installation and was operational from 3Q 2012.

A vacuum conveyor system (VCS) integrates cuttings transport and cleaning, real-time monitoring systems, and automation components. It operates cleanly and safely, without high-gforces, cuttings degradation, or fluid mist and vapor pollution, thereby improving the working environment. To date, the shaker has been introduced to drilling sites in the North Sea and in the US Marcellus shale play.

Previously, the Maersk Giant used four traditional shale shakers for primary solids control. Following discussions between Cubility, Maersk Drilling, Talisman Energy Norway, and DONG Energy, these were replaced with three MudCubes.

Cubility and Maersk set three key goals to determine the success of the project: improving the shaker room’s working environment, reducing the mud volume typically lost over standard solids control equipment, and minimizing the corresponding waste volume, while improving overall drilling fluid performance. Throughout the drilling process, these and other parameters were monitored to assess the new shakers’ impact.

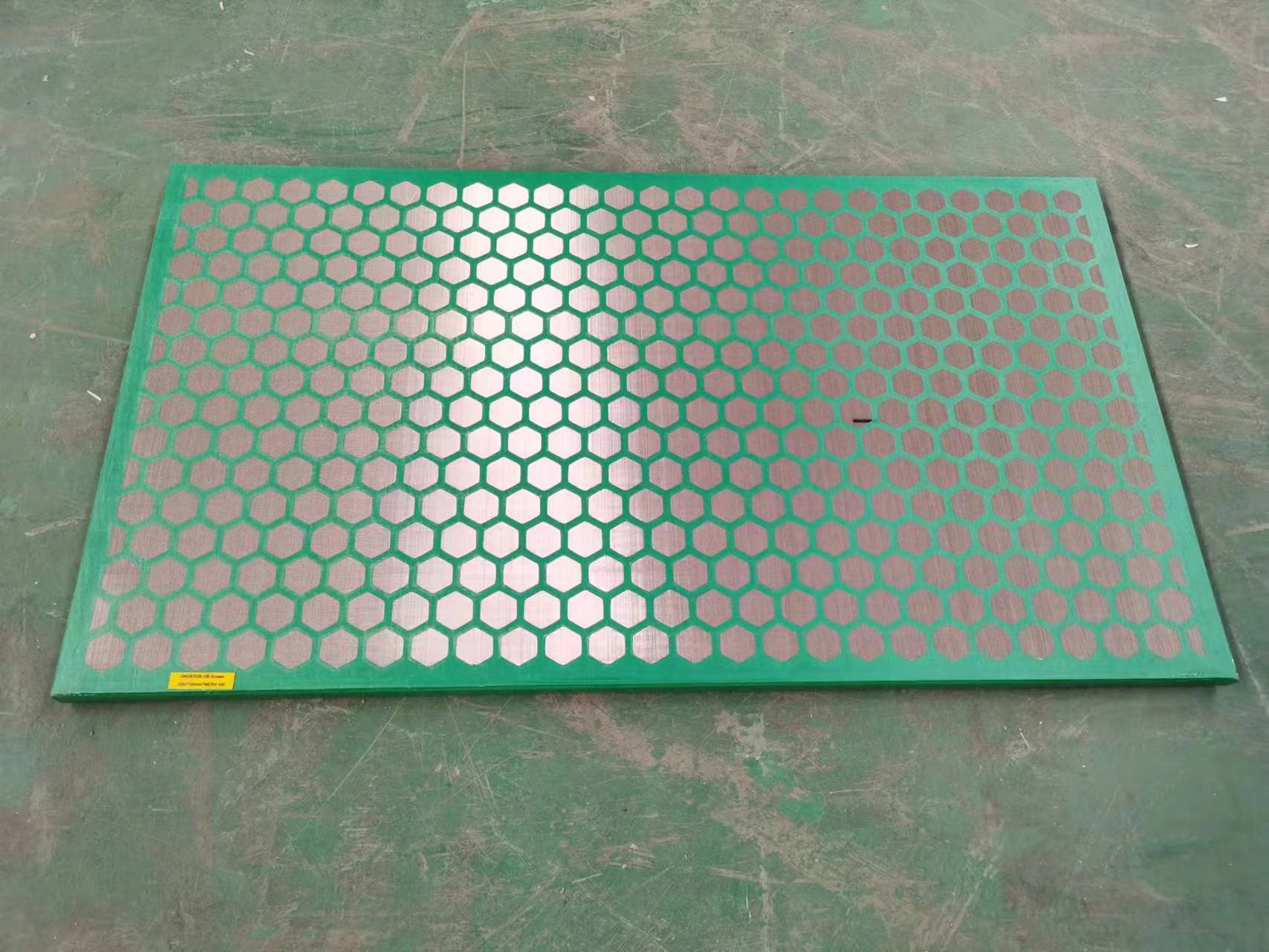

The new shakers receive fluid and cuttings conventionally through a distribution box. From here, the integrated VCS processing technique takes effect. First, fluid is distributed evenly via adjustable gates across a replaceable, non-tensioned, woven wire, stainlesssteel screen (filterbelt), secured to a drivebelt, and vacuumed through the entire area of the filterbelt via a vacuum tray. Then, an air-knife blows on the wet cuttings and returns the fluid to the active system. While the unit does not shake, micro-vibration devices are employed to increase maximum flow capacity.

As available screen openings are covered by mud flow, air travels more quickly through the remaining openings. This increased air velocity, coupled with a continuously rotating screen, offers high resistance to screen blinding, minimizing the potential for fluid to cascade off the unit and into the drilling waste. Additionally, a secondary air-knife removes residual solids from the screen and deposits them in the discharge line.

After passing through a secondary filtration system, clean fluid is separated from air and gas, through a negative-pressure generating unit. The unit’s cyclone filter captures moisture and returns it to the active system. This recovery feature minimizes losses to evaporation and benefits the environment. Finally, the collected, filtered, drilling fluid is deposited back into the active system via gravity flow.

Maersk and Cubility had high expectations for improvements in HSE conditions and waste volume reductions. The ratios between solids and fluid in the drilling waste on the Maersk Giant, when using traditional shakers, ranged from 1:2.20 to 1:2.72, while 1:1 is commonly accepted by the industry as a very good ratio. However, the ratio between solids and fluid was reduced to 1:0.13, following the shaker replacement.

Waste and costs were reduced, due to a reduction in the waste transported ashore and reuse of drilling fluid. The lifespan of the system’s filterbelt is 40 times longer than that of a traditional screen, from less wear on the surface system, pump liners, etc.

Improvements in HSE conditions were seen, particularly in noise, emissions, and vibration. Noise-levels were reduced to 68dBA from about 95dBA, well below the recommended 83dBA NORSOK standard for a 12-hour working day. Oil vapor and oil mist issues were completely eliminated in the shaker room. Finally, there was no need for structural reinforcement on the platform, due to the system’s comparatively light weight and lowfrequency vibration.

SWACO A result of the project, workers on the Maersk Giant have start calling the shaker room the “cube lounge,” due to its emission-, noise- and vibrationfree environment. The Maersk Giant is currently on contract to DONG Energy, working on the Trym field in the Norwegian sector of the North Sea. OE