California Institute of Technology, Pasadena, CA

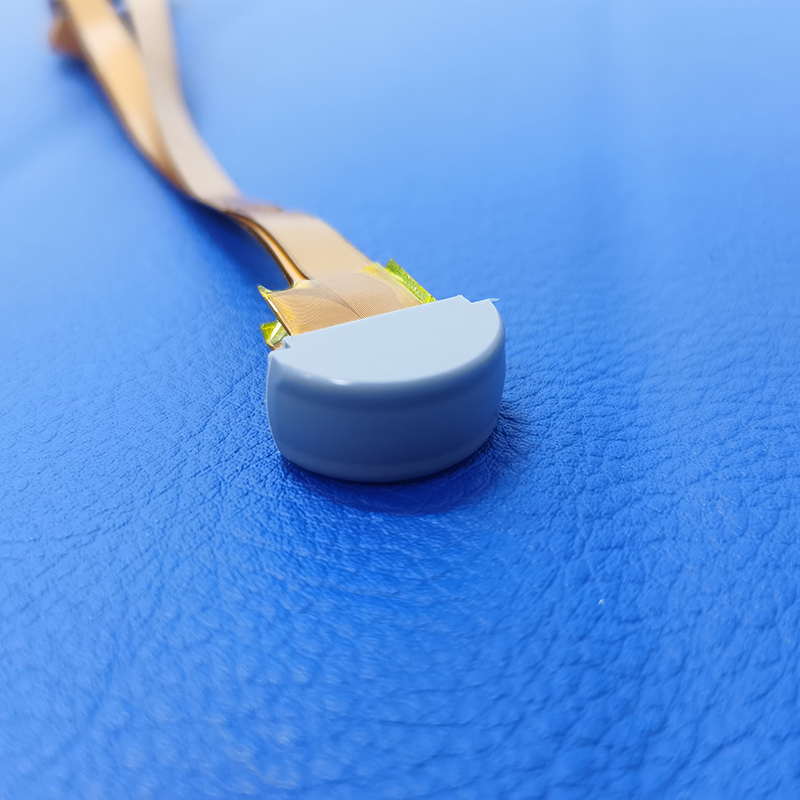

There are times when scientific progress comes in the form of discovering something completely new. Other times, progress boils down to doing something better, faster, or more easily. New research from the lab of Caltech’s Lihong Wang, the Bren Professor of Medical Engineering and Electrical Engineering, is the latter. In a paper published in the journal Nature Biomedical Engineering, Wang and postdoctoral scholar Yide Zhang show how they have simplified and improved an imaging technique they first announced in 2020. Portable Ultrasound Probe

That technique, a form of photoacoustic imaging technology called photoacoustic topography through an ergodic relay (PATER), is a specialty of Wang’s group.

In photoacoustic imaging, laser light is pulsed into tissue where it is absorbed by the tissue’s molecules, causing them to vibrate. Each vibrating molecule serves as a source of ultrasonic waves that can be used to image the internal structures in a fashion similar to how ultrasound imaging is performed.

However, photoacoustic imaging is technologically challenging because it produces all its imaging information in one short burst. To capture that information, early versions of Wang’s photoacoustic imaging technology required arrays of hundreds of transducers to be pressed against the surface of the tissue being imaged, which made the technology complicated and expensive.

Wang and Zhang reduced the number of required transducers by using a device called an ergodic relay, which slows down the rate at which information in the form of vibrations flows into a transducer. As explained in a previous story about PATER:

In computing, there are two main ways to transmit data: serial and parallel. In serial transmission, the data are sent in a single stream through one communication channel. In parallel transmission, several pieces of data are sent at the same time using multiple communication channels.

In the system Wang designed with 512 sensors, all of the transducers were working at the same time, with each taking in part of the data about the ultrasonic vibrations generated by the laser pulse.

Since the ultrasonic vibrations from the system come in one short burst, a single transducer would be overwhelmed if it were used to try and collect all the data in that short amount of time. That’s where the ergodic relay comes in.

As Wang describes it, an ergodic relay is a sort of chamber around which sound can echo. When the ultrasonic vibrations pass through the ergodic relay, they are stretched out in time.

The latest version of this technology, called photoacoustic computed tomography through an ergodic relay (PACTER) goes even further, allowing the system to operate using a single transducer that, through the use of software, can collect as much data as 6,400 transducers.

PACTER improves on PATER in two other ways, said Wang. One improvement is that PACTER can create three-dimensional images, whereas PATER can only generate 2D images. This has been enabled by the development of improved software.

“Transitioning to 3D imaging significantly escalates the data requirement. The challenge was funneling the immensely increased data through a single transducer,” Zhang said. “Our solution emerged by altering our approach. Rather than a direct and computationally intensive method of reconstructing 3-D images from the single-transducer data, we first expanded one transducer into thousands of virtual ones. This idea simplified the process of 3D image reconstruction, aligning it more closely with the traditional methods in our photoacoustic imaging.”

Second, unlike PATER, PACTER does not need to be calibrated each time it is used. “With PATER, we had to calibrate it each time to use it and that’s just not practical. We got rid of this per-use single-time calibration,” Wang said.

Calibration was needed because when the system fires a pulse of laser light into tissue, an “echo” of that pulse would bounce back into the transducer, preventing it from sensing direct ultrasound information.

Wang says PACTER gets around that issue by adding a delay line to the system. The delay line forces the echo to take a longer physical path on its way back to the transducer so that it arrives after the direct ultrasound information has been received.

“Even though I always said this was possible, I knew it would be challenging,” Wang said.

The paper describing the work, “Ultrafast longitudinal imaging of haemodynamics via single-shot volumetric photoacoustic tomography with a single-element detector,” appears in the November 30, 2023 issue of Nature Biomedical Engineering.

For more information, contact Emily A. Velasco at This email address is being protected from spambots. You need JavaScript enabled to view it..

This article first appeared in the May, 2024 issue of Photonics & Imaging Technology Magazine.

Read more articles from this issue here.

Read more articles from the archives here.

A Breakthrough in Fast-Charging Lithium-Sulfur Batteries

Humanoid Robots: The Next-Generation Robotic Workforce

All-Liquid Iron Flow Battery Is Safe, Economical

The First High-Resolution, 3D-Printed Brain

A New Process for Turning CO2 into Sustainable Fuel

Giving Household Robots Common Sense

Testing New Unmanned Aircraft Technologies

100% Cloud CAD - The Future of Design Is Now

Virtual Twin as an Accelerator of ADAS and AD Development

Innovating Aircraft Interiors: How to Decrease Weight and Optimize Parts Production

Accelerated SDV Development: Virtual Prototypes of Vehicle Super-Integration Processors

Handling Unexpected Biocompatibility Test Results in Medical Device Development

My Opinion: Energy Storage, Part 2

Creating Synthetic Cell Images for Enhanced Microscopy Analysis

Answering Your Questions: Lithium-Air Battery vs. Lithium-Ion

How Much Do You Know About Programmable DC Power Supplies?

Comparison Between Wave Soldering and Reflow Soldering

Printed Electronics: The Future Is Flexible

How Much Do You Know About Fiber Optics?

Polycarbonate Seen As Top Choice for LED Lighting

Mapping Gravity with Motion Control

The Modern Industrial Workhorse: PID Controllers

The Basics of Encoder Selection

Researchers Demonstrate Cutting-Edge Chip Technology for Ultra-Low Power AI...

Smart Sensor Technology for the IoT

Networking the IoT with IEEE 802.15.4/6LoWPAN

Opening Up the Potential of Thin-Film Electronics for Flexible Chip Design

Laser Beam vs. Electron Beam Welding Which process works best for what?

Jet-Propelled Sea Creatures Could Improve Ocean Robotics

Mechanical Carbon Materials for Aircraft Seal Applications

Brushless Motors for In-Tank Fuel Pumps

How Helios Horizon Is Taking Electric Aircraft to New Altitudes

3 eVTOL Companies to Watch in 2024: Archer Aviation, Joby Aviation, and Lilium

The Future of eVTOL Battery Technology

By submitting your personal information, you agree that SAE Media Group and carefully selected industry sponsors of this content may contact you and that you have read and agree to the Privacy Policy.

You may reach us at privacy@saemediagroup.com.

You may unsubscribe at any time.

Refurbished Ultrasound © 2009-2024 SAE Media Group