Working on the nanoscale gives researchers a lot of insight and control when fabricating and characterizing materials. In larger scale manufacturing, as well as in nature, many materials have the capacity for flaws and impurities that can disrupt their complex structure. This creates several weak points that can easily break under stress. This is common with most glass, which is why it is thought of as such a delicate material.

Scientists at the Columbia University, University of Connecticut, and the U.S. Department of Energy’s (DOE) Brookhaven National Laboratory were able to fabricate a pure form of glass and coat specialized pieces of DNA with it to create a material that was not only stronger than steel, but incredibly lightweight. Materials that possess both of these qualities are uncommon, and further research could lead to novel engineering and defense applications. The results were published in Cell Reports Physical Science. 932-22-9

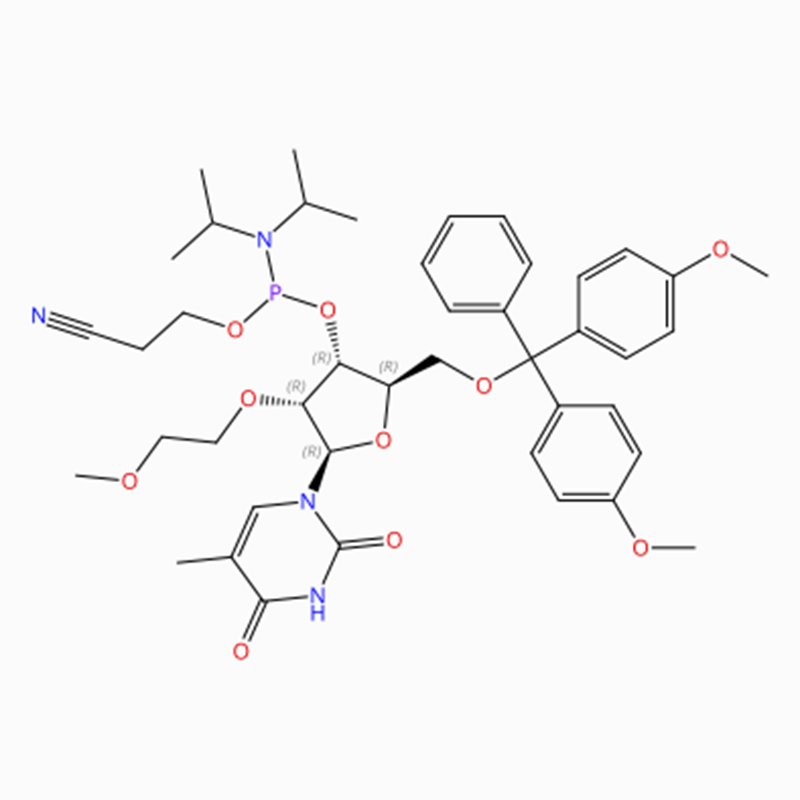

In living things, deoxyribonucleic acid, more commonly known as DNA, carries biological information that instructs the cells of organisms on how to form, grow, and reproduce. The material DNA is made of is known as a polymer, a class of tough, elastic materials that includes plastic and rubber. Their resilience and simplicity have intrigued material scientists and inspired many interesting experiments. Oleg Gang, a Materials Scientist at the Center for Functional Nanomaterials (CFN), a DOE Office of Science User Facility at Brookhaven Lab, and a professor at Columbia University, has been leveraging DNA’s unique properties for materials synthesis for years, resulting in numerous discoveries. This novel technology has inspired an array of innovative applications — from drug delivery to electronics.

Gang had previously worked with the paper’s lead author, Brookhaven postdoctoral researcher Aaron Michelson, on an experiment using DNA structures to build a robust framework for novel materials. DNA molecules behave in an interesting way. The individual nucleotides, basic units of nucleic acids like DNA and RNA, dictate the bonding between complementary sequences. The precise way they bond to each other allows scientists to develop methods to engineer the folding of DNA into specific shapes referred to as origami, named after the Japanese art of paper folding. These DNA shapes are nanoscale building blocks that can be programmed using addressable DNA bonds to “self-assemble.” This means that well-defined structures with a repeating pattern can spontaneously form from these origami DNA blocks.

These blocks then cling together to form a larger lattice — a structure with a repeating pattern. This process allows scientists to build 3D ordered nanomaterials from DNA and integrate inorganic nanoparticles and proteins, as demonstrated by the group’s previous studies. After gaining understanding and control of this unique assembly process, Gang, Michelson, and their team were then able to explore what can be achieved when that biomolecular scaffolding was used to create silica frameworks that preserve the scaffold architecture.

“We focused on using DNA as a programmable nanomaterial to form a complex 3D scaffold,” said Michelson, “and we wanted to explore how this scaffold will perform mechanically when transferred into more stable solid-state materials. We explored having this self-assembling material cast in silica, the main ingredient in glass, and its potential.”

When put to the test, the glass-coated DNA lattice was shown to be four times stronger than steel. What was even more interesting was that its density was about five times lower. While there are materials that are strong and considered fairly lightweight, it has never been achieved to this degree.

While there is still a lot of work to be done before scaling up and thinking about the myriad of applications for such a material, there are still reasons for materials scientists to be excited about what this means going forward. The team plans to look at other materials, like carbide ceramics, that are even stronger than glass to see how they work and behave. This could lead to even stronger lightweight materials in the future.

For more information, contact Denise Yazak at This email address is being protected from spambots. You need JavaScript enabled to view it..

This article first appeared in the February, 2024 issue of Tech Briefs Magazine.

Read more articles from this issue here.

Read more articles from the archives here.

A Breakthrough in Fast-Charging Lithium-Sulfur Batteries

Humanoid Robots: The Next-Generation Robotic Workforce

All-Liquid Iron Flow Battery Is Safe, Economical

The First High-Resolution, 3D-Printed Brain

A New Process for Turning CO2 into Sustainable Fuel

Giving Household Robots Common Sense

Testing New Unmanned Aircraft Technologies

100% Cloud CAD - The Future of Design Is Now

Virtual Twin as an Accelerator of ADAS and AD Development

Innovating Aircraft Interiors: How to Decrease Weight and Optimize Parts Production

Accelerated SDV Development: Virtual Prototypes of Vehicle Super-Integration Processors

Handling Unexpected Biocompatibility Test Results in Medical Device Development

My Opinion: Energy Storage, Part 2

Creating Synthetic Cell Images for Enhanced Microscopy Analysis

Answering Your Questions: Lithium-Air Battery vs. Lithium-Ion

How Much Do You Know About Programmable DC Power Supplies?

Comparison Between Wave Soldering and Reflow Soldering

Printed Electronics: The Future Is Flexible

How Much Do You Know About Fiber Optics?

Polycarbonate Seen As Top Choice for LED Lighting

Mapping Gravity with Motion Control

The Modern Industrial Workhorse: PID Controllers

The Basics of Encoder Selection

Researchers Demonstrate Cutting-Edge Chip Technology for Ultra-Low Power AI...

Smart Sensor Technology for the IoT

Networking the IoT with IEEE 802.15.4/6LoWPAN

Opening Up the Potential of Thin-Film Electronics for Flexible Chip Design

Laser Beam vs. Electron Beam Welding Which process works best for what?

Jet-Propelled Sea Creatures Could Improve Ocean Robotics

Mechanical Carbon Materials for Aircraft Seal Applications

Brushless Motors for In-Tank Fuel Pumps

How Helios Horizon Is Taking Electric Aircraft to New Altitudes

3 eVTOL Companies to Watch in 2024: Archer Aviation, Joby Aviation, and Lilium

The Future of eVTOL Battery Technology

By submitting your personal information, you agree that SAE Media Group and carefully selected industry sponsors of this content may contact you and that you have read and agree to the Privacy Policy.

You may reach us at privacy@saemediagroup.com.

You may unsubscribe at any time.

Protected Nucleosides © 2009-2024 SAE Media Group