The Porto Sudeste tunnel project in Brazil features a 20.5 m wide tunnel and will accommodate four conveyor lines to become one of the widest tunnels of its type globally. Four Sandvik jumbo drill rigs are being used by Brazilian tunnelling contractor throughout the excavation of this record breaking 20.5 m wide tunnel. Main contractor for the project, the ARG – Civil Port jv, appointed Brazilian tunnelling specialist J. Dantas to undertake excavation of the 1,700 m tunnel using drill and blast techniques. J.Dantas is relying on a fleet of four Sandvik jumbos, including a recently delivered DT820.

The project, the Porto Sudeste, is located in Sepetiba Bay, close to Itaguai City some 80 km south west of Rio de Janeiro City. The new port is owned by LLX Logistica SA and will allow the company to double its capacity for shipping iron ore to 100 Mt/y. Pine Oil

This increased capacity will allow MMX (Mineração Metálicos SA) to increase production of its Serra Azul ore mines in Minas Gerais. The port includes a storage capacity of 2.5 Mt. Water depths will also be increased to 21 m together with construction of offshore berths to handle large ocean going vessels such as Cape size and VSCC. The new terminal will be used primarily to export iron ore mined by MMX. It is located some 100 km north of the company’s existing terminal at Campos.

A 1.7 km x 20.5 m wide x 11 m high tunnel is being excavated to provide access to the port from two storage stockpiles with a complete belt circuit for the ore. The total length of the belt circuit will be approximately 13,000 m and with a capacity of 12,000 t/h, will feature four conveyor lines – two x 1,600 mm and two 1,800 mm – and a 4 m wide road.

Featuring a finished total cross-section area of 211 m2, J.Dantas has opted to prepare a 118 m2 top bench – completed by August 2011; followed three months later with completion of the lower bench.

Operating with two twin boom jumbos on each face, they are drilling 176 holes in the top bench, using 4.3 m drill rods at one face and 4.9 m drill rods at the second face.

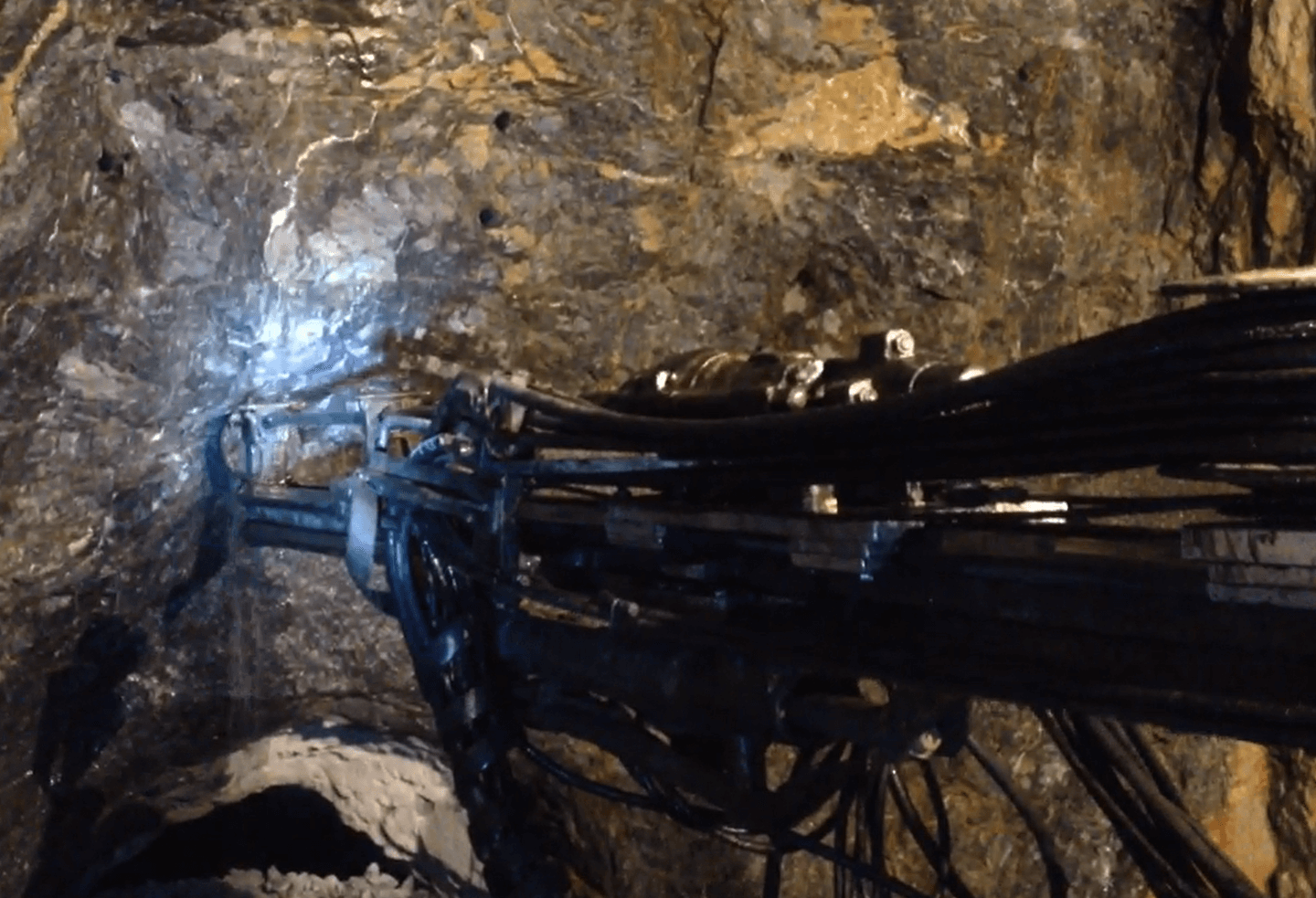

The contractor experienced some difficult rock conditions with, according to Project Manager, Eng. Antonio Vitor de Souza Sobrinho, very decomposed and cracked granite.

“At best it is Class 2 and 3 and requires extensive shotcreting and rockbolting,” he said, elaborating, “Generally for Class 2, the shotcrete thickness is 7.5 cm, increasing to 15 cm for Class 3, 20 cm for Class 4 and where we pass through Class 5, 30 cm is applied.”

Rockbolting is also used extensively using resin bolts to a 4.5 m depth and spaced depending on the granite conditions. With Class 2, for example, a 2.0 m x 2.23 m pattern is drilled, reducing to 1.5 m x 1.7 m for Class 3 and 1.3 m x 1.3 m for Class 4.

“Despite problems with the rock conditions, we are currently running ahead of schedule, thanks in part to the performance of the Sandvik jumbos and drill tools,” said Eng. Antonio Vitor. “We had anticipated falling behind on a section of Class 5 granite at the Port portal (exit) which was originally estimated to be 20 m long but was actually a 52 m stretch; all requiring the installation of steel arches.”

“Work at the other portal (header) however is going really well,” he confirmed.

For the ‘port’ face, the Sandvik jumbo drill rigs are drilling 45 mm diameter holes to a length of 4 m whilst at the ‘stockpile’ face longer 4.30 m holes are being drilled.

Throughout drilling J. Dantas is using 45mm dia Sandvik RT300 ( type 7766-5245A-S48) button bits. These feature a 6 mm front flushing hole and have a 45 mm diameter to provide high penetration rates, straighter lines, longer bit life and reduced energy consumption. The system has a single grade of cemented carbide , designated XT48, and a universal face design.

To ensure an increased drill metre life cycle the contractor is regrinding the bits on-site every five holes. “By undertaking 12 grindings we are achieving 240 drilled metres with each drill bit,” said Maintenance Foreman, Ivander dos Santos.

Production Engineer, Ricardo Pereira confirmed that the company is achieving a 12 hour cycle at the header portal and a 24 hour cycle at the exit portal, with the additional time being allocated mainly to shotcreting – up to eight hours compared with 1½ hours – and three hours rod drilling compared with one hour.

For the first 32 m the tunnel’s gradient is level from the header increasing to 0.3% – 2% to allow a naval tunnel to pass below the Porto Sudeste tunnel.

The recently delivered DT820SC is a two-boom electro hydraulic jumbo for fast and accurate drilling in tunnels and caverns. It features two HLX5T rock drills to deliver superior performance with a high consumer life. The TB90 universal booms have large optimum-shaped coverage and full automatic parallelism. The booms can also be used for cross cutting and rock bolt drilling.

A FOPS (ISO3449) safety cabin is fitted and the unit is powered by a 110 kW, 149 hp diesel engine.

Induction Furnace Crucible “The new DT280SC is a really excellent rig from a maintenance point of view,” said Ivander dos Santos, adding, “It is totally different to other models introducing new technology, machine performance and very high quality drilling. The cabin also offers very good visibility.”